Poly-vinyl versatate-vinyl acetate-ethylene emulsion and emulsion polymerization preparation method

A technology of polyvinyl tertiary carbonate and tertiary ethylene carbonate, applied in the field of terpolymer and its preparation, can solve the problems of unsatisfactory water resistance, solvent resistance and acid resistance, restricting the application and development of VAE emulsion, low strength, etc. , to achieve the effect of moderate molecular weight and distribution, excellent creep resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. Ingredients

[0027] a. Preparation of surfactants

[0028] With deionized water as solvent, weigh 26 kg of compound polyvinyl alcohol (i.e. polyvinyl alcohol 05-88, polyvinyl alcohol 14-98 and polyvinyl alcohol 17-88 mixed according to mass ratio 30:49:45), emulsifier 3.2kg of octylphenol polyoxyethylene ether and 1.8kg of reducing agent zinc sulfoxylate formaldehyde are prepared into 500kg of surfactant solution for use.

[0029] b. Preparation of monomer solution

[0030] 540 kg of vinyl acetate (VAc) with a purity of 99.5% and 5.4 kg of vinyl tertiary carbonate were mixed uniformly to obtain a monomer solution for use.

[0031] c. Preparation of oxidizing agent

[0032] Weigh 2.57 kg of hydrogen peroxide solution with a mass concentration of 35%, and dilute it to prepare an oxidizing agent hydrogen peroxide solution with a mass concentration of 1.8% for use.

[0033] 2. Polymerization

[0034] Put 500kg of surfactant solution and 2 / 3 of monomer solution into...

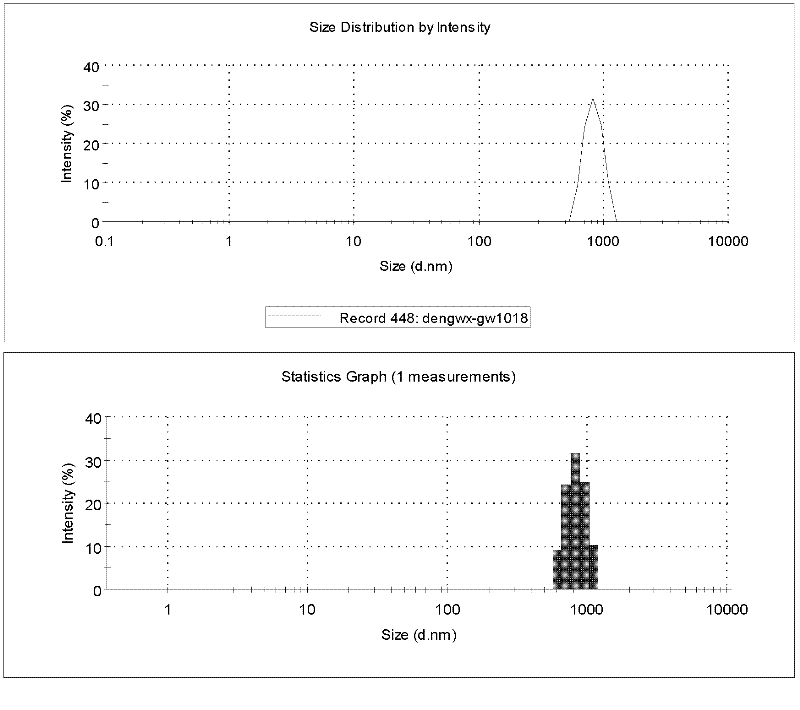

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com