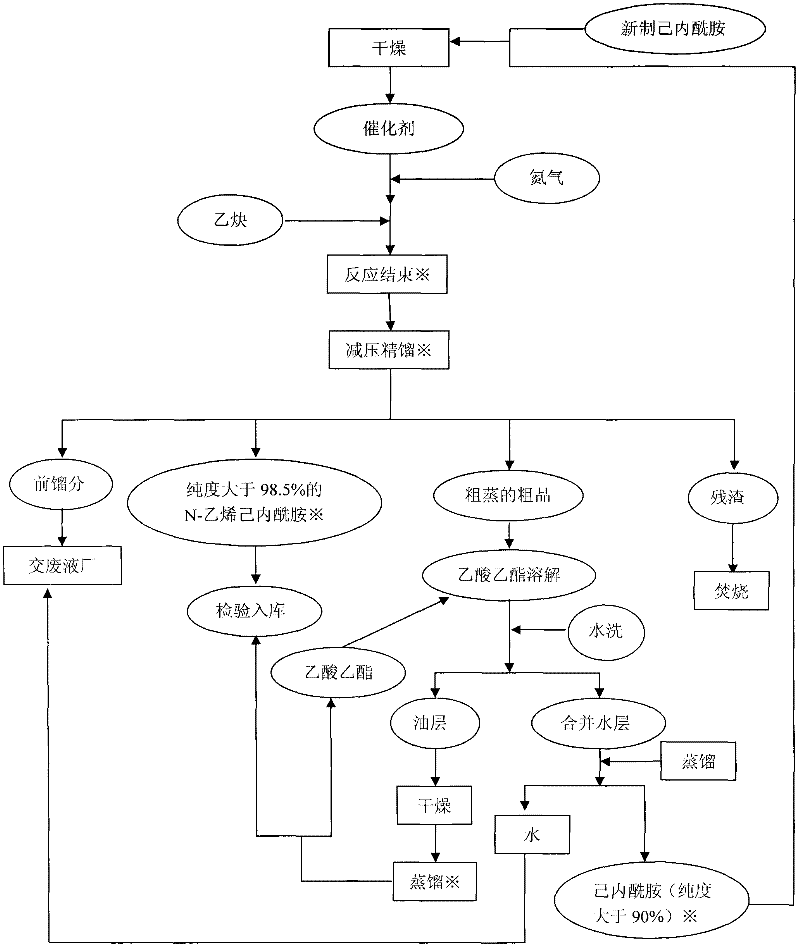

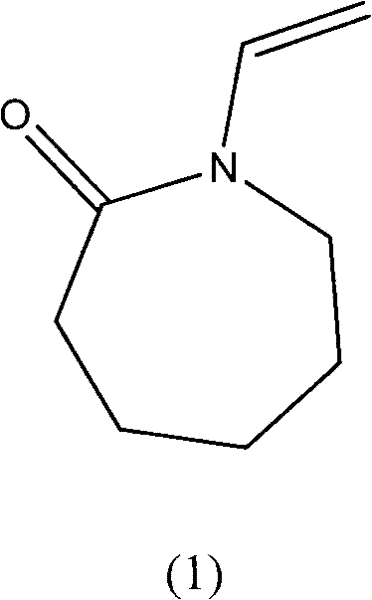

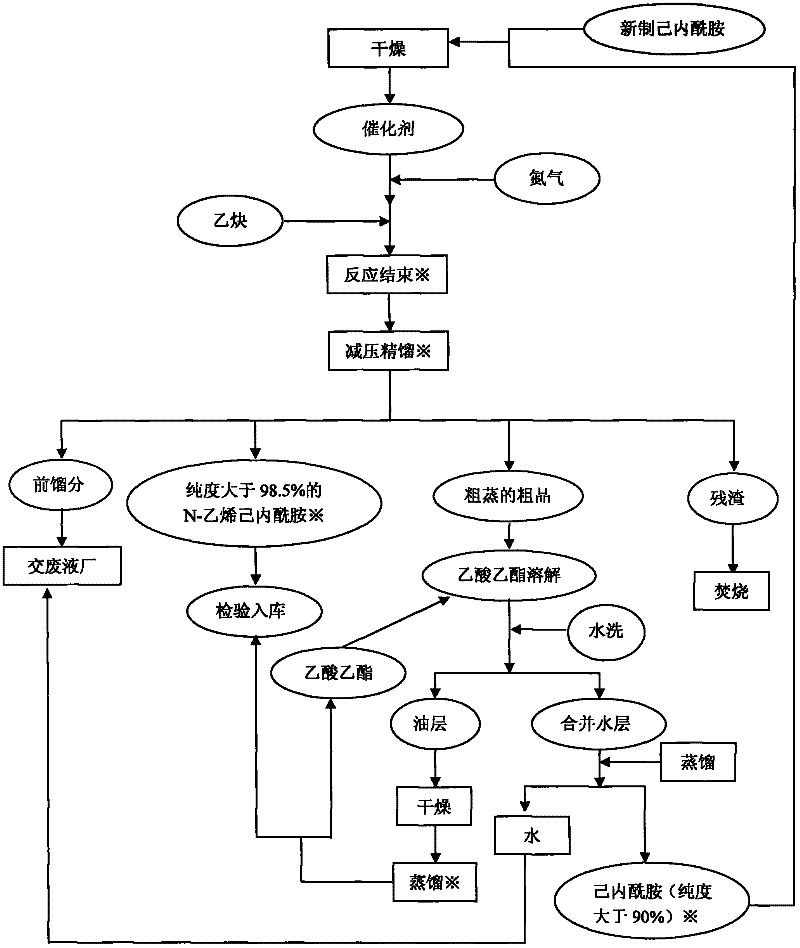

Preparation method for N-vinyl caprolactam capable of recycling raw materials

A vinyl caprolactam, caprolactam technology, applied in the direction of organic chemistry and the like, can solve the problems of difficult to realize industrialization, numerous process steps, dangerous process operation, etc., and achieve the effect of reducing solvent consumption, shortening reaction time, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Take 800 kg of dried caprolactam (purity > 95%) and 16 kg of potassium hydroxide in the jet loop reactor, pass nitrogen at 90°C for 2 hours to discharge the air and moisture in the reactor, and close Reactor (keep a certain amount of nitrogen in the kettle), feed acetylene, the temperature is controlled at 130 ± 3 ° C, the reaction stops after 10 hours, and 906 kg of N-vinyl caprolactam with a content of 58% (GC) is obtained mother liquor.

[0039] 2. 906 kilograms of N-vinyl caprolactam mother liquors with a content of 58% (GC) obtained in step 1 are placed in a rectifying still of 1.5 tons, start rectifying after the closed system, and set the still temperature to be 150°C. The vacuum degree is 30mmHg, adjust the reflux ratio of the rectifying tower, and after the reflux at the top of the rectifying tower is stable for one hour, the distillate tends to be stable and start to collect products, GC monitoring, after collecting 355 kg of products with a purity of more ...

Embodiment 2

[0043] 1. Take 800 kilograms of dry raw material caprolactam (purity > 95%) and 16 kilograms of potassium hydroxide in the jet loop reactor, pass nitrogen at 100 ° C for 2 hours to discharge the air and moisture in the reactor, and close the reaction Still (keep a certain amount of nitrogen in the still), feed acetylene, the temperature is controlled at 100 ± 3 ° C, the reaction stops after 16 hours, and 902 kg of N-vinyl caprolactam crude product with a content of 56.6% (GC) is obtained mother liquor.

[0044] 2. Place 902 kilograms of N-vinyl caprolactam crude product mother liquor with a content of 56.6% (GC) obtained in step 1 in a 1.5-ton rectification kettle, start rectification after the closed system, and set the kettle temperature to 150°C , the vacuum degree is 30mmHg, adjust the reflux ratio of the rectifying tower, and after the reflux at the top of the rectifying tower is stable for one hour, the fraction tends to be stable and begins to collect products, GC monit...

Embodiment 3

[0048] 1. Take dry 800 kilograms of raw material caprolactam (purity > 95%) and 16 kilograms of potassium methylate in the jet loop reactor, pass nitrogen at 90 ° C for 2 hours to discharge the air and moisture in the reactor, and close the reactor (keep a certain amount of nitrogen in the still), feed acetylene, and the temperature is controlled at 150 ± 3° C., and the reaction stops in 8 hours to obtain 912 kg of N-vinyl caprolactam mother liquor with a content of 58.9% (GC).

[0049] 2. 912 kilograms of N-vinyl caprolactam mother liquors with a content of 58.9% (GC) obtained in step 1 are placed in a rectifying still of 1.5 tons, start rectifying after the airtight embodiment, and set the temperature of the still to be 150°C. The vacuum degree is 20mmHg, after one hour of reflux at the top of the kettle, the distillate tends to be stable and begins to collect products. GC monitors and collects 377 kg of products with a purity of more than 98.5%. After the purity is lower tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com