Method for preparing tetrapropyl ammonium hydroxide by utilizing bipolar membrane electrodialysis

A technology of tetrapropylammonium hydroxide and bipolar membrane electrodialysis, which is applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of resin quality decline, high price, difficult separation, etc., and achieve Reduce energy consumption, achieve the effect of raw material cost, low cost and multiple selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

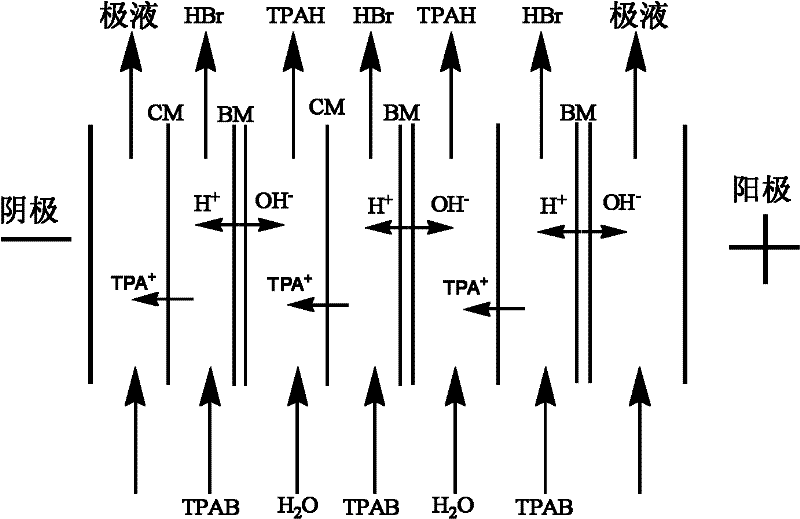

[0032] The preparation of tetrapropyl ammonium hydroxide adopts bipolar membrane electrodialysis equipment to carry out, and described bipolar membrane electrodialysis equipment is made up of 2 bipolar membrane electrodialysis devices connected in series, and described bipolar membrane electrodialysis device is made up of two sides The polar liquid chamber is composed of an electrodialysis compartment sandwiched between the polar liquid chambers on both sides.

[0033] A bipolar membrane electrodialysis device with a two-compartment structure, the area of each membrane is 200mm×400mm, a total of 20 pairs (that is, 20 groups of units composed of bipolar membranes and cation exchange membranes) bipolar membranes, cation exchange membranes Form a membrane stack, the bipolar membrane electrodialysis device is composed of anolyte chambers on both sides, the anolyte chamber is divided into an anode chamber and a cathode chamber, the left side is a cathode chamber, and the right sid...

Embodiment 2

[0036] The preparation of tetrapropyl ammonium hydroxide adopts bipolar membrane electrodialysis equipment to carry out, and described bipolar membrane electrodialysis equipment is made up of 2 bipolar membrane electrodialysis devices connected in series, and described bipolar membrane electrodialysis device is made up of two sides The polar liquid chamber is composed of an electrodialysis compartment sandwiched between the polar liquid chambers on both sides.

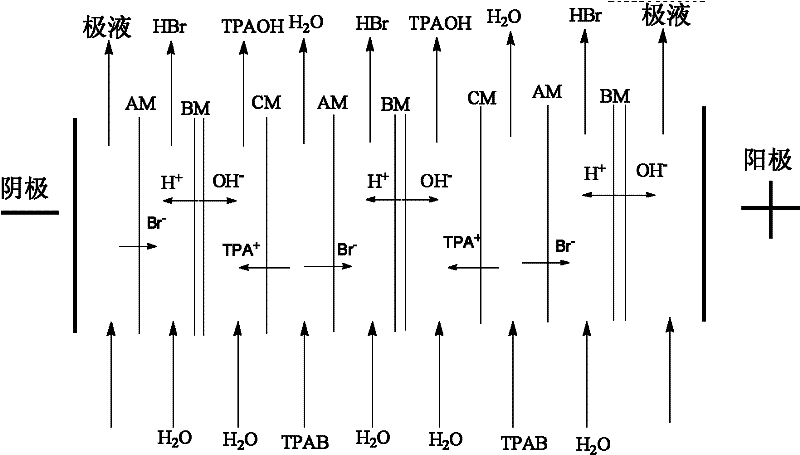

[0037] A bipolar membrane electrodialysis device with a three-compartment structure is adopted. The area of each membrane is 200 mm × 800 mm. A total of 40 pairs of bipolar membranes, anion and cation exchange membranes form a membrane stack. The bipolar membrane electrodialysis device consists of two The polar liquid chamber on the side is composed of the electrodialysis compartment sandwiched between the polar liquid chambers on both sides. The polar liquid chamber is divided into a cathode chamber and an anode cham...

Embodiment 3

[0040] The preparation of tetrapropyl ammonium hydroxide adopts bipolar membrane electrodialysis equipment to carry out, and described bipolar membrane electrodialysis equipment is made up of 2 bipolar membrane electrodialysis devices connected in series, and described bipolar membrane electrodialysis device is made up of two sides The polar liquid chamber is composed of an electrodialysis compartment sandwiched between the polar liquid chambers on both sides.

[0041] A bipolar membrane electrodialysis device with a four-compartment structure is adopted. The area of each membrane is 200mm×800mm. A total of 40 pairs of bipolar membranes, anion exchange membranes and 80 cation exchange membranes form a membrane stack. The bipolar membrane electrodialysis The dialysis device is composed of anolyte chambers on both sides and an electrodialysis compartment sandwiched between the anolyte chambers on both sides. The anolyte chamber is divided into a cathode chamber and an anode cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com