Humic acid biofertilizer and its preparation method

A humic acid and bio-fertilizer technology, applied in the field of agricultural fertilizers, can solve problems such as land fertility decline and land compaction, and achieve the effects of reducing fertilizer consumption, reducing labor, and enhancing natural environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

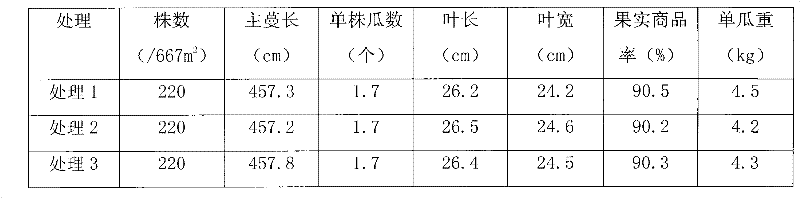

Embodiment 1

[0042] A kind of humic acid bio-fertilizer, comprises the organic raw material of following weight portion:

[0043] Humic Acid 50

[0044] Ammonium bicarbonate 5

[0045] rapeseed 5

[0046] Tung oil 1

[0047] Rice Bran 1

[0048] Chicken 0.1

[0049] Alcohol 0.1

[0050] soybeans 1

[0051] Prepare as follows:

[0052] A. Weigh humic acid, rapeseed oil, tung oil, rice bran, and soybean, respectively, and pulverize them by weight, mix and stir with chicken blood and alcohol;

[0053] B. Send the mixture of step A into the fermentation tank, add an appropriate amount of enzyme agent, and ferment for 12 days. The temperature of the fermentation tank is kept at 20 degrees. After fermentation, gray hair-like mycelium is produced, and the fermentation with water content below 15% is obtained. thing;

[0054] C, pulverizing the fermented product to obtain humic acid biological fertilizer without inorganic fertilizer.

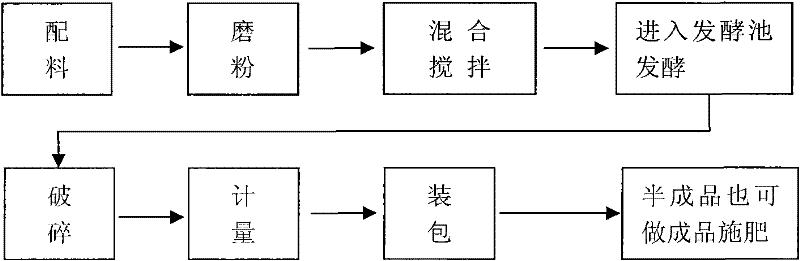

[0055] The specific preparation steps can be seen in...

Embodiment 2

[0057] A kind of humic acid bio-fertilizer, comprises the organic raw material of following weight portion:

[0058] Humic Acid 70

[0059] ammonium bicarbonate 15

[0060] rapeseed 15

[0061] Tung Youku 7

[0062] Rice Bran 7

[0063] Chicken blood 0.5

[0064] Alcohol 0.5

[0065] soybeans 5

[0066] A. Weigh humic acid, rapeseed oil, tung oil, rice bran, and soybean, respectively, and pulverize them by weight, mix and stir with chicken blood and alcohol;

[0067] B, the mixture of step A is sent into the fermentation tank, and an appropriate amount of enzyme agent is added, fermented for 17 days, and the temperature of the fermentation tank is maintained at 30 degrees. After fermentation, gray hair-like mycelium is produced, and the water content is below 15%. fermented product;

[0068] C, pulverizing the fermented product to obtain humic acid biological fertilizer without inorganic fertilizer.

Embodiment 3

[0070] A kind of humic acid bio-fertilizer, comprises the organic raw material of following weight portion:

[0071] Humic Acid 60

[0072] ammonium bicarbonate 10

[0073] rapeseed 8

[0074] Tung oil 5

[0075] Rice Bran 5

[0076] Chicken blood 0.2

[0077] Alcohol 0.3

[0078] soybeans 2

[0079] A. Weigh humic acid, rapeseed oil, tung oil, rice bran, and soybean, respectively, and pulverize them by weight, mix and stir with chicken blood and alcohol;

[0080] B, the mixture of step A is sent into the fermentation tank, and an appropriate amount of enzyme agent is added, fermented for 15 days, and the temperature of the fermentation tank is maintained at 25 degrees. After fermentation, gray hair-like mycelium is produced, and the water content is below 15%. fermented product;

[0081] C, pulverizing the fermented product to obtain humic acid biological fertilizer without inorganic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com