Method for producing drinking water deep purification activated carbon by utilizing Datong coal

A deep purification, activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of complex production method of agglomerated activated carbon, high product production cost, unstable performance, etc. The effect of stable product quality and good drinking water purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

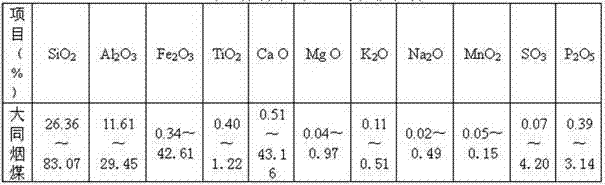

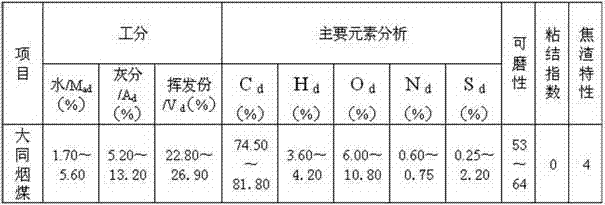

[0030] A method for preparing active carbon for deep purification of drinking water from Datong bituminous coal, including crushing, grinding, briquetting, carbonization, activation and screening processes, the raw coal used is Datong bituminous coal; the crushing process is: sending the raw coal into Known crushing equipment is crushed to a particle size of 3-5mm; the described grinding process is: the raw material crushed coal is pulverized by a ball mill, and more than 99% of the particles after grinding are required to pass through a 200 mesh sieve; the described briquetting process is : Utilize the dry rolling granulator equipment to carry out dry briquetting molding of the powder after grinding under the pressure of 27MPa; the carbonization process is: sending the briquetting material into the horizontal external heating rotary furnace Carbonization, carbonization temperature: 500°C, carbonization time: 38min, heating rate: 10°C / min; the activation process is: put the car...

Embodiment 2

[0032] A method for preparing activated carbon for deep purification of drinking water from Datong coal, comprising crushing, pulverizing, briquetting, carbonization, activation and screening processes, the raw coal used is Datong bituminous coal; the crushing process is: crushing the raw coal into The particle size of 3-5mm; the described milling process is: more than 99% of the particles after the raw material crushing and coal milling are required to pass through a 200 mesh sieve; The briquetting process is carried out under the following conditions; the carbonization process is: send the briquette material into the carbonization furnace for carbonization, the carbonization temperature is 530°C, the carbonization time is 45min, and the heating rate is 3°C / min; the activation process is: Send the carbonized material into the activation furnace for activation, the activator is water vapor, the activation temperature: 800°C, and the activation time: 230 minutes; the screening p...

Embodiment 3

[0035] A method for preparing activated carbon for deep purification of drinking water from Datong coal, comprising crushing, pulverizing, briquetting, carbonization, activation and screening processes, the raw coal used is Datong bituminous coal; the crushing process is: crushing the raw coal into The particle size of 3-5mm; the described milling process is: the particle fineness of the raw material crushed coal after milling requires more than 99% to pass through a 200 mesh sieve; the described briquetting process is: the powder after grinding is at 29MPa The briquetting process is carried out under a certain pressure; the carbonization process is: send the briquette material into the carbonization furnace for carbonization, the carbonization temperature: 550°C, the carbonization time: 74min, and the heating rate is 5°C / min; the activation process The method is: send the carbonized material into the activation furnace for activation, the activator is water vapor, the activati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com