Method for preparing nitrogen doping hollow carbon nanocages

A technology of nanocage and hollow carbon, which is applied in the direction of nanocarbon, nanotechnology, nanotechnology, etc., can solve the problems such as the preparation method of nitrogen-doped carbon nanocage that has not yet been seen, and achieve easy recycling and reuse, high specific surface area, mesoporous high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

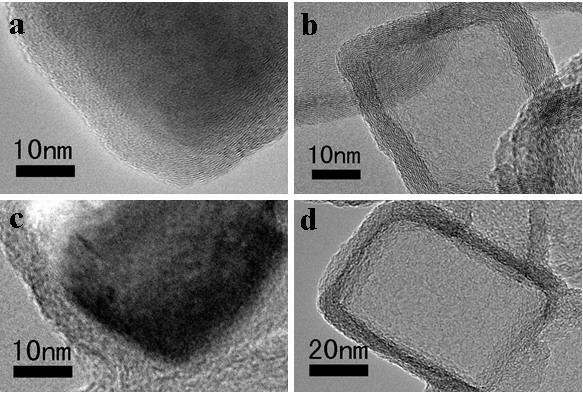

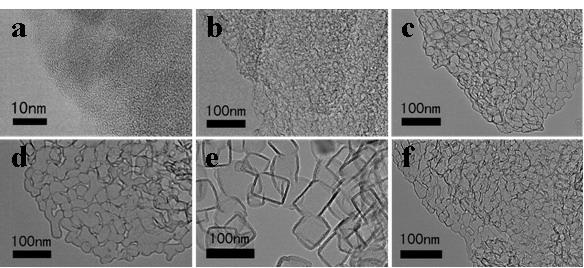

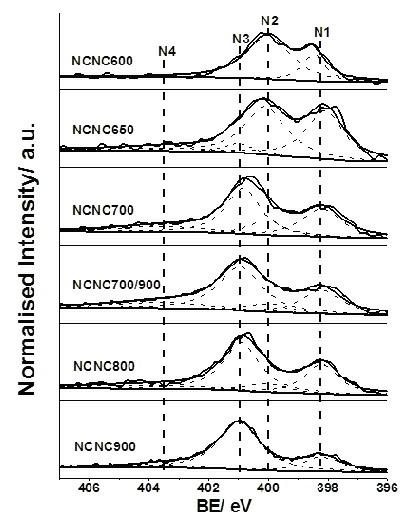

Embodiment 1

[0042] Weigh basic magnesium carbonate and add it into the reaction tube, spread it evenly, put it into the central area of the tube furnace, then repeatedly fill it with argon and evacuate it with a mechanical pump for 3-5 times. Under an argon atmosphere (50 sccm), the temperature was raised to 650 °C at a rate of 10 °C per minute, and 0.020 ml / min of pyridine was input with a convection pump, and the reaction was carried out for 60 min. ) protection down to room temperature, collect the powder from the reaction tube, soak in 1mol / L hydrochloric acid solution for 60min, filter, wash with deionized water until neutral, and dry to obtain nitrogen-doped hollow carbon nanocages. After testing, the nitrogen content is about 12%. The specific surface area is about 1800 m 2 ?g -1 , the pore volume can reach 4.20 cm 3 ?g -1 , the particle size is about 10~30 nm, and the mesoporosity is higher than 99.7%.

Embodiment 2

[0044] Weigh basic magnesium carbonate and add it into the reaction tube, spread it evenly, put it into the central area of the tube furnace, then repeatedly fill it with argon and evacuate it with a mechanical pump for 3-5 times. Under an argon atmosphere (50 sccm), the temperature was raised to 700 °C at a rate of 10 °C per minute, and 0.020 ml / min of pyridine was input with a convection pump, and the reaction was carried out for 60 min. ) protection down to room temperature, collect the powder from the reaction tube, soak in 10mol / L hydrochloric acid solution for 60min, filter, wash with deionized water until neutral, and dry to obtain nitrogen-doped hollow carbon nanocages. After testing, the nitrogen content is about 11%. The specific surface area is about 1650 m 2 ?g -1 , the pore volume can reach 3.90 cm 3 ?g -1 , the particle size is about 10~40 nm, and the mesoporosity is higher than 99.5%.

Embodiment 3

[0046] Weigh basic magnesium carbonate and add it into the reaction tube, spread it evenly, put it into the central area of the tube furnace, then repeatedly fill it with argon and evacuate it with a mechanical pump for 3-5 times. Under an argon atmosphere (50 sccm), the temperature was raised to 800 °C at a rate of 10 °C per minute, and 0.020 ml / min of pyridine was input with a convection pump, and the reaction was carried out for 60 min. ) protection down to room temperature, collect the powder from the reaction tube, soak in 1mol / L hydrochloric acid solution for 30min, filter, wash with deionized water until neutral, and dry to obtain nitrogen-doped hollow carbon nanocages. After testing, the nitrogen content is about 10%. The specific surface area is about 1100 m 2 ?g -1 , the pore volume can reach 2.50 cm 3 ?g -1 , the particle size is about 10~40 nm, and the mesoporosity is higher than 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com