Method for warehousing cigarette cases via automatic logistics system

A logistics system and piece of cigarette technology, applied in packaging, conveyor belt packaging, etc., can solve the problems of high human resource cost and labor intensity, damaged and dangerous pieces of cigarette group, etc., to improve the stability of equipment operation, Eliminate damage, reduce the cost of human resources and the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

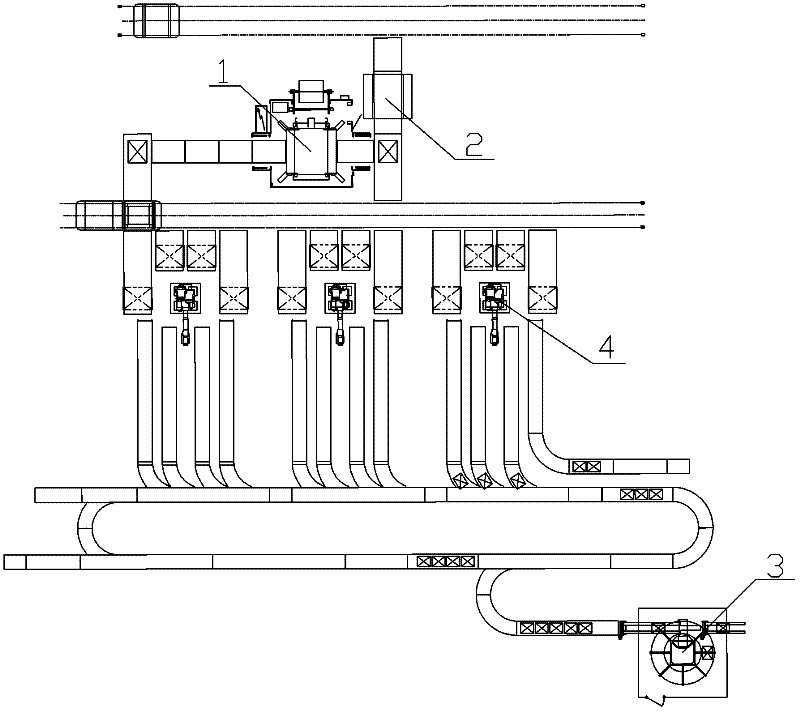

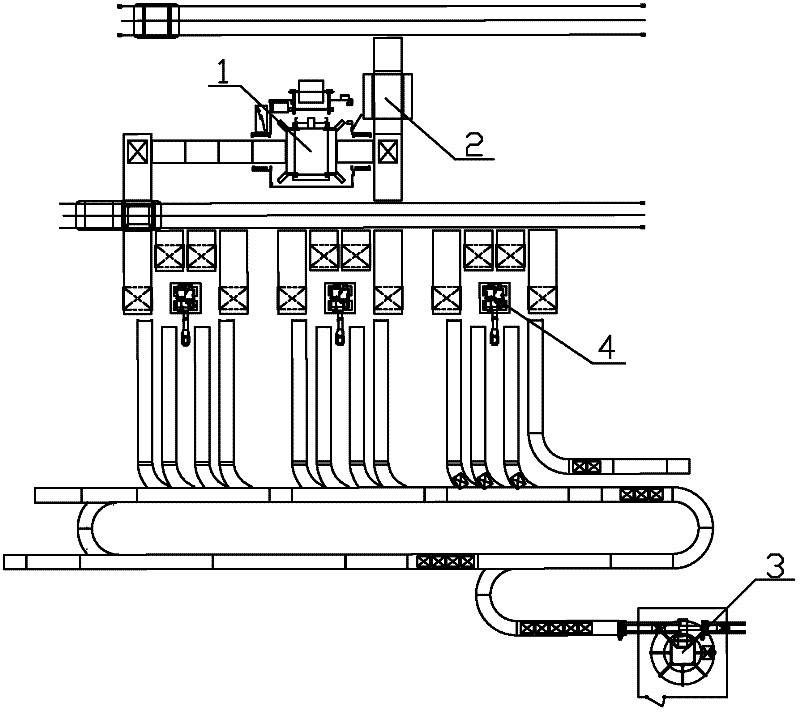

[0013] Such as figure 1 As shown, the pieces of cigarettes are output by the spiral descending machine 3 and sent to the stacking robot 4; the stacking robot 4 stacks the pieces of cigarettes into a cigarette group; 1. First check the height of the piece cigarette group, call the preset film model in the system according to the height of the piece cigarette group, cut the plastic mold used for the film, and then coat the piece cigarette group. The plastic mold adopts a single-layer polyethylene stretch film; after the cigarette pack passes through the automatic laminating machine 1, it also passes through the manual binding station 2, and then is sent to the finished product warehouse for storage; the manual binding station 2 does not work under normal conditions, when the automatic laminating machine When 1 breaks down, manual strapping platform 2 starts to work.

[0014] Since the cigarette packs are covered with a plastic film, there will be no shift and deformation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com