Hot sealing and cold cutting device for plastic film bag making machine

A technology of plastic film and cold-cutting device, which is applied in the direction of container manufacturing machinery, packaging, transportation and packaging, etc. It can solve the problems of unqualified bag shape, skew and trimming dislocation, and unsightly appearance, so as to improve appearance characteristics and increase production Efficiency, method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

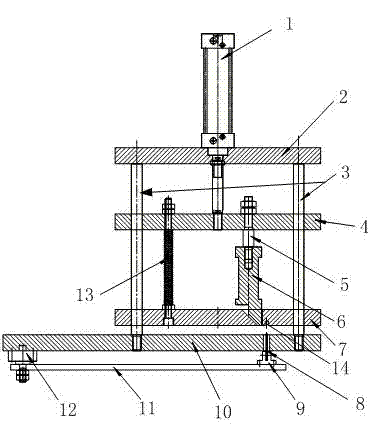

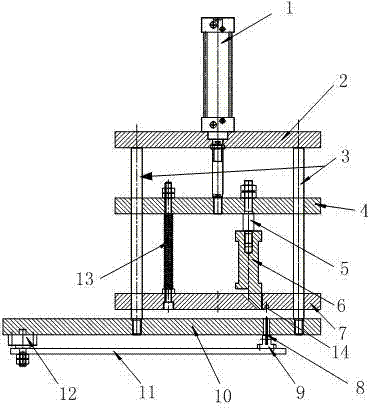

[0012] like figure 1 As shown, the heat-sealing and cold-cutting device for plastic film bag making machine includes an upper fixed plate 2, a lower fixed plate 10, and a cylinder 1. The upper end of the upper fixed plate 2 is fixed with the cylinder 1 and installed in the center of the upper fixed plate 2. At the position, the two ends of the upper fixed plate 2 are fixed on the lower fixed plate 10 by installing the guide rod 3, the guide rod 3 is provided with a slidable upper movable plate 4 and a lower movable plate 7 with spacing, the upper movable plate 4 and the cylinder The piston rod of 1 is fixed, the distance between the upper movable plate 1 and the same side of the lower movable plate 7 is fixed by a spring suspension rod 13, and a heat-sealing knife device 6 is provided between the distance on the other same side, and the heat-sealing knife device 6 The upper end is fixed with the upper movable plate 4 through the connecting rod 5, and the heat-sealing knife at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com