Automatic machining machine tool for four-station valve body

An automatic processing, four-station technology, applied in the field of machine tools, can solve the problems of low production efficiency, low efficiency, no longer suitable for large-scale production of valves, etc., to improve processing efficiency, ensure stability, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

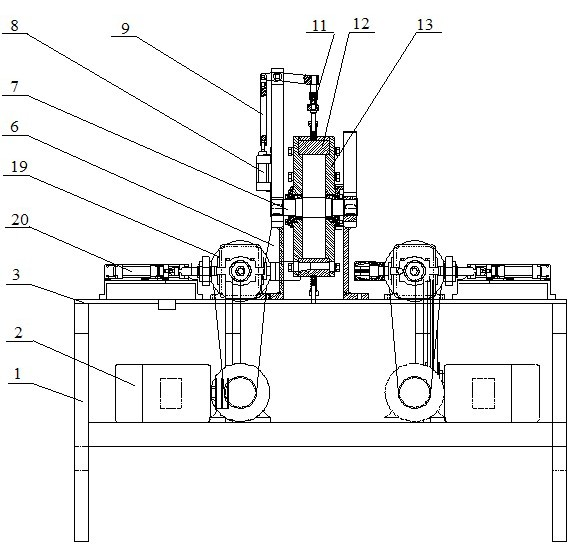

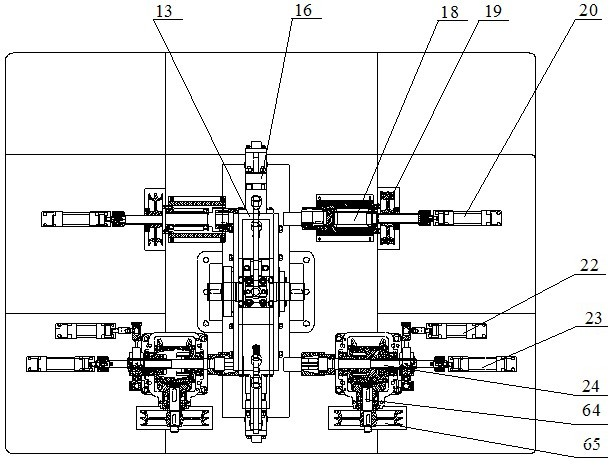

[0056] like figure 1 , figure 2 As shown, the four-station valve body automatic processing machine tool of the present invention includes a rotary mechanism and a bracket; the rotary mechanism is arranged on the bracket;

[0057] The support includes a frame 1 and a frame 3; the frame 3 is supported by the frame 1;

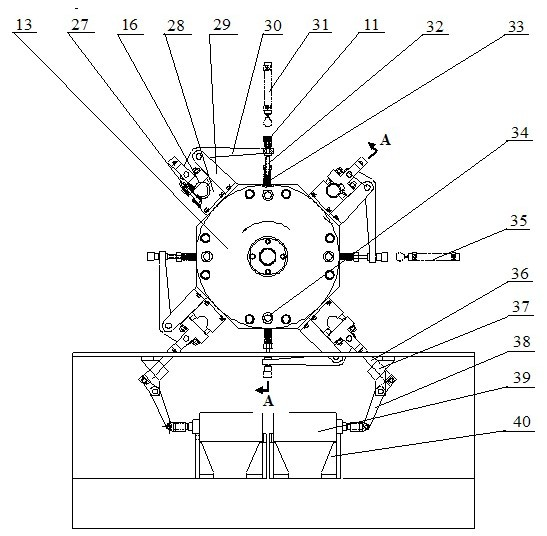

[0058] like image 3 , Figure 4 As shown, the rotary mechanism includes a rotary disc 13, which is arranged on the main shaft 7, and the rotary disc 13 is connected with the overrunning clutch 44 through bolts, and the outer circle of the overrunning clutch 44 cooperates with the gear 43 through a needle roller; the overrunning clutch 44 is also arranged on the on spindle 7;

[0059] Under the action of the hydraulic cylinder, the rack moves left and right, driving the gear 43 meshed with it to rotate, and the gear 43 drives the rotary plate 13 to rotate through the overrunning clutch 44 to realize the conversion of the station;

[0060] There are four grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com