Automatic ladle slag outflow detection system and method thereof

An automatic detection and steel slag technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze fluids, etc., can solve the problem of affecting the judgment of the slag under the large ladle, such as the control of sliding nozzles, and achieve the effect of easy playback analysis and avoiding signal overshoot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. The following examples are only used to illustrate and explain the present invention, but not to limit the technical solution of the present invention.

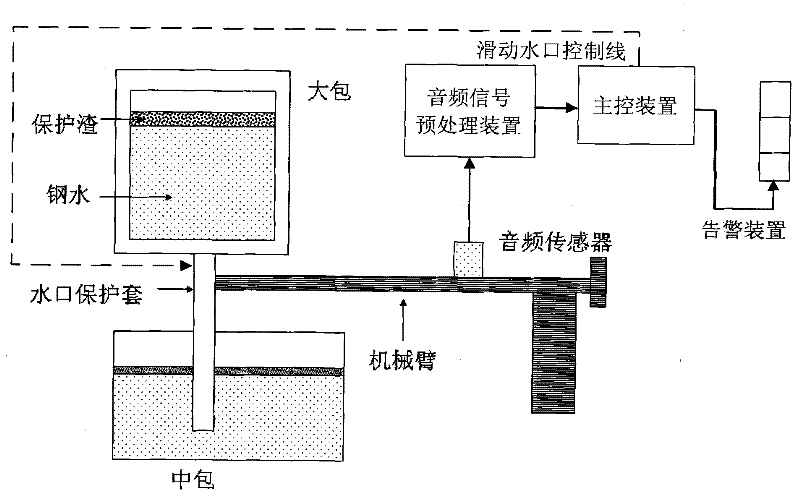

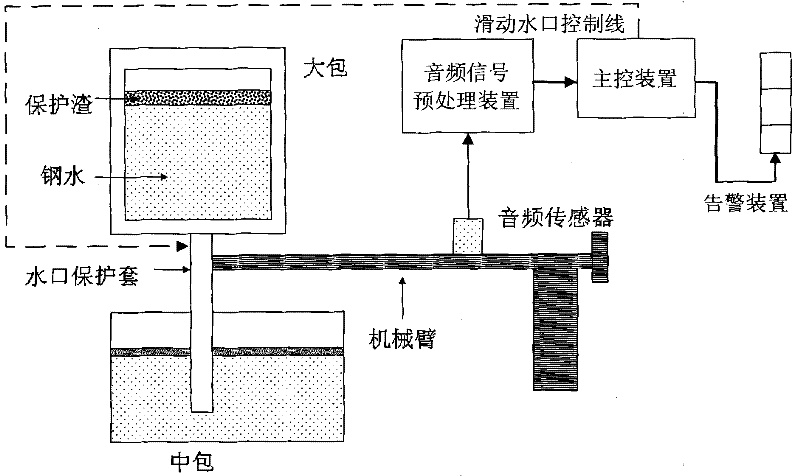

[0053] like figure 1 Shown is the structure of an embodiment of the automatic detection system for slag slag provided by the present invention, which includes an audio sensor, an audio signal preprocessing device and a main control device connected in sequence, wherein:

[0054] The audio sensor is used to collect the corresponding sound signal when the molten steel and steel slag flow out of the nozzle, and convert it into a corresponding analog waveform and output it to the audio signal preprocessing device;

[0055] The above-mentioned audio sensor can be installed inside or outside the end of the manipulator away from the nozzle, such as figure 1 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com