Process and die for forging big circular ring with rectangular section

A technology with a rectangular cross-section and a circular ring, which can be used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., and can solve the problems of complex processing technology and waste of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

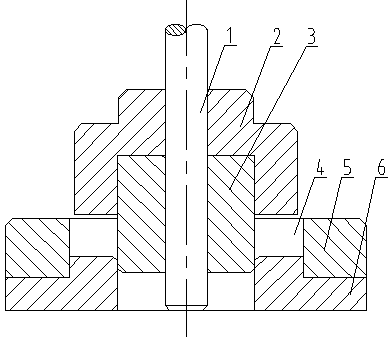

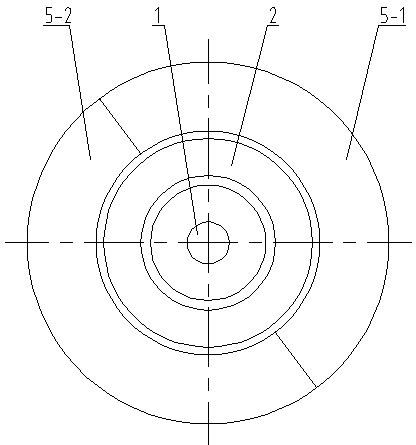

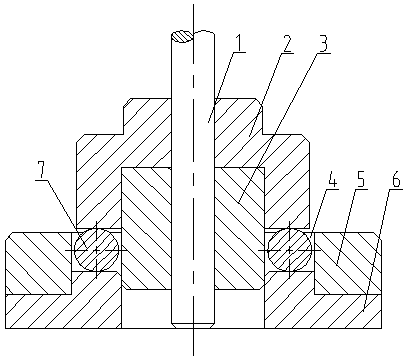

[0018] see as Figure 3-4 Shown:

[0019] The forging process and mold of the rectangular cross-section large ring of the present invention are illustrated by taking the manufacturing of a gear blank with an outer diameter of Φ483.9mm; an inner diameter of Φ430.5mm; and a thickness of 21mm as an example.

[0020] 1. Cutting. According to the size requirements of the large circular ring with a rectangular cross-section of the processed part, the round steel bar with a suitable diameter is accurately calculated according to the metal processing theory, and the length of the bar is accurately calculated from the diameter of the selected round bar to ensure the maximum Material utilization. Manufacture the ring gear blank with the size of Φ483.9×Φ430.5×21 (mm) according to the needs, that is, to manufacture a rectangular ring with a cross-section of 26.7×21 (mm), and calculate it with a metal allowance of 5%. The diameter of the round steel should be Φ27.38mm, and the round ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com