Automatic hydraulic channeling machine

A grooving machine and hydraulic technology, which is applied in the field of automatic hydraulic grooving machines, can solve difficult problems such as groove technology, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

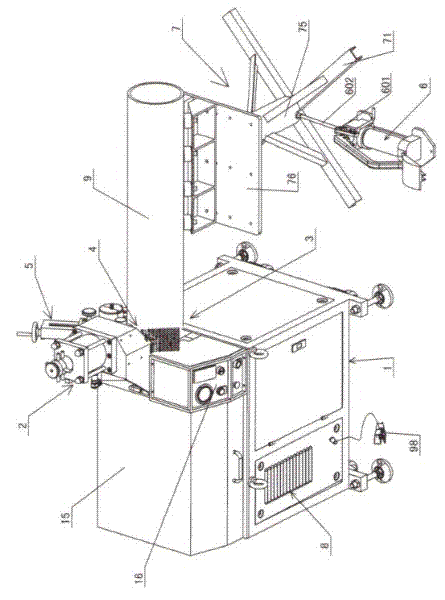

[0032] The invention relates to an automatic hydraulic grooving machine, such as Figure 1-Figure 18 As shown, it is characterized by including:

[0033] ① The frame part is equipped with 1, including the chassis 11, the table 12, the caster 13, the machine foot 14, the shield 15 and the panel 16;

[0034] ② Oil cylinder system 2, including oil cylinder base 21, piston rod 22, piston 23, cylinder body 24, oil cylinder upper end cover 25, upper and lower oil pipes 26, 27, adjustment nut 282, adjustment rod 285, lock nut 281, scale cover 284 ;

[0035] ③ Grooving mechanism 3, including main motor 31, power head 4, coupling 32, main shaft 33, bearing 34, knurling wheel 35, pressure roller guide shaft 43, pressure roller 41 and pressure roller shaft 42;

[0036] ④ guide wheel mechanism 4, including guide wheel shaft 51, guide wheel 52, sliding adjustment knob 53, adjustment bolt 54, guide block 55, hand wheel 56, screw mandrel 57, screw mandrel slider 58 and guide wheel frame 59...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com