Steel-framed structural greenhouse

A greenhouse and steel frame technology, applied in horticulture, greenhouse cultivation, climate change adaptation and other directions, can solve the problems of long production process, low cost, and the plastic cover is not easy to open casually, so as to achieve easy cover and open, increase firmness and The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

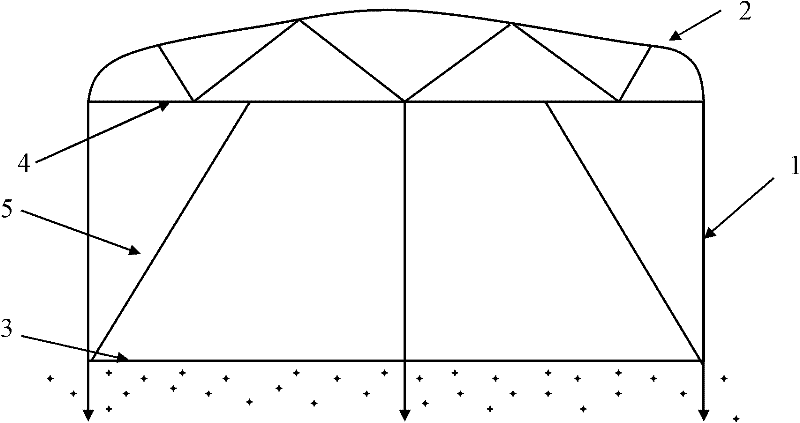

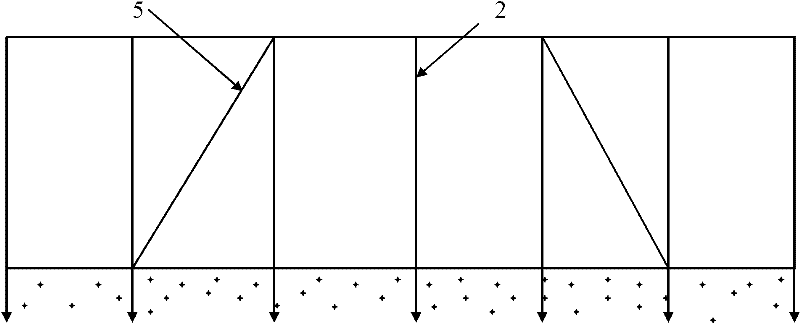

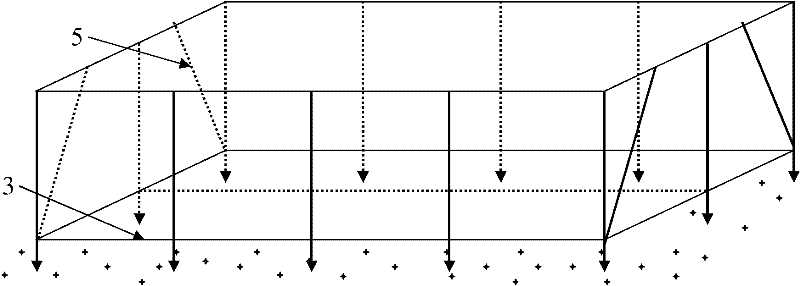

[0015] Choose a piece of farmland with flat terrain and uniform fertility as the site for greenhouse construction. Build a length 19, width 9, height 2.5m, such as figure 1 -The plastic greenhouse shown in Figure 5, the side is the plastic film or wall that can be opened and closed, the plastic film on the shed is fixed by the rope that is tied with sandbags, and the ground contact part of the side is then directly compacted with sandbags. The required materials, specifications and dosage are as follows:

[0016]

[0017]

[0018] Based on the materials listed above, according to figure 1 -The rainproof plastic greenhouse with steel frame structure built by the method in Figure 5 has been well tested in the monitoring of water demand and consumption of crops in the semi-arid area of western Liaoning. The stability is better than that of ordinary vegetable greenhouses, ensuring the scientific research and observation. accuracy and continuity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com