Diaphragm for flow battery and preparation method thereof

A liquid flow battery and diaphragm technology, which is applied to battery pack parts, fuel cell parts, circuits, etc., can solve problems such as battery performance deterioration, vanadium ion penetration, and battery efficiency reduction, and achieve excellent chemical stability and long-term The effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

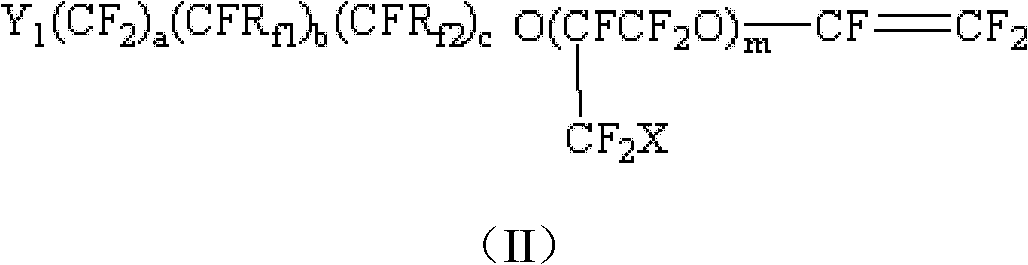

[0049] The exchange capacity is 1.35mmol / g tetrafluoroethylene and m=0, a=2, b=0, c=0, Y in the formula (III) i =SO 2 The perfluorosulfonic acid resin formed by alkali hydrolysis and acidification after monomer copolymerization of F is dispersed in DMF to form a 50% dispersion liquid, and the dispersion liquid is prepared into a film with a thickness of 30 microns by solution casting. One side spray formula (III) a=3, Y 1 , Y 2 = F and formula (V) b = 6 molar ratio 1: 1 mixture of two substances, the thickness is 5 microns, heated at 250 ° C for 60 min to obtain a flow battery separator modified by sulfonimide polycondensate .

Embodiment 2

[0051] The exchange capacity is 1.00mmol / g tetrafluoroethylene and m=1, a=2, b=0, c=0, Y in the formula (II) i =SO 2 The monomer of F is copolymerized into a perfluorosulfonic acid resin formed by alkali hydrolysis and then acidification, and is dispersed in DMSO to form a 40% dispersion liquid. This dispersion liquid is prepared into a film with a thickness of 50 microns by solution casting. One side of the film is sprayed with formula (III) a=6, Y 1 , Y 2 =F and the mixture of formula (VI) d=3 molar ratio 1: 1, thickness is 2 microns, spray formula (IV) c=6 on the other side of film, X 1 、X 2 = Cl and formula (VI) d = 6 mixture of molar ratio 1:1, the thickness is 1 micron; the films sprayed on the above two surfaces are first reacted at 50°C for 100min, and then heated to 250°C for 100min to obtain One side was -SO 2 Flow battery separator modified by NHCO-polycondensate and modified by imide on the other side.

Embodiment 3

[0053] The exchange capacity is 1.20mmol / g tetrafluoroethylene and m=1, a=2, b=0, c=0, Y in the formula (II) 1 =SO 2 F monomer and m=0, a=4, b=0, c=0, Y 1 =SO 2 The monomer of F is terpolymerized to form a perfluorosulfonic acid resin through an extruder, and a film with a thickness of 80 μm is extruded at 190°C. After the above film was hydrolyzed with 10% sodium hydroxide at 80°C for 8 hours and acidified with sulfuric acid for 2 hours, the formula (III) a=6, Y was cast on one side of the film 1 , Y 2 = F and formula (VI) d = 6 mixture of molar ratio 1:1, thickness is 8 microns. Then put the film at 200°C for 3 hours heat reaction to form one side with -SO 2 NHCO-polycondensate modified flow battery separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com