Floating junction solar cell back passivation structure based on heterojunction and preparation technology thereof

A technology for solar cells and preparation processes, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of energy band mismatch at heterojunctions and affect the collection efficiency of photogenerated holes, and achieve low surface recombination rate , avoid the effect of high temperature process and high open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

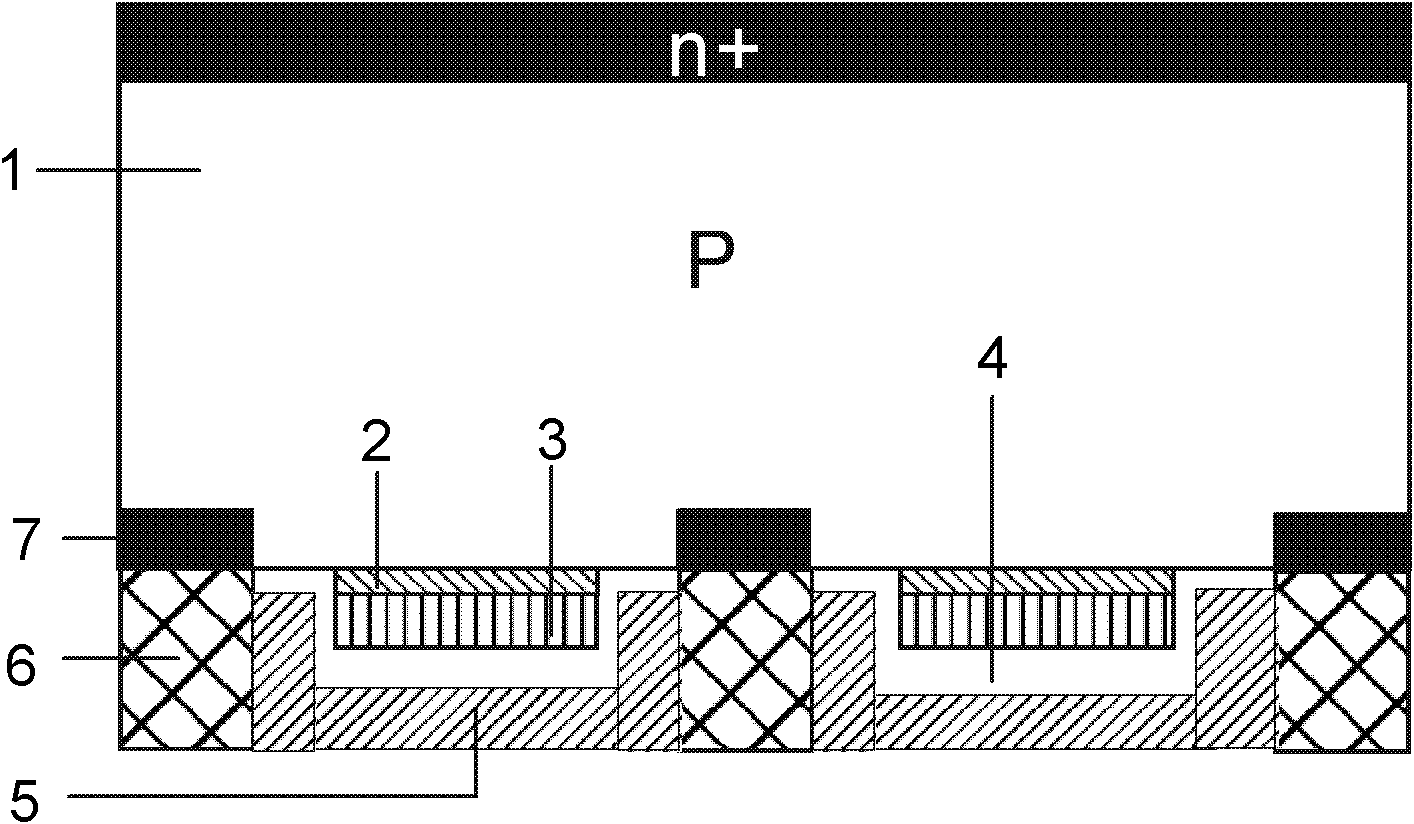

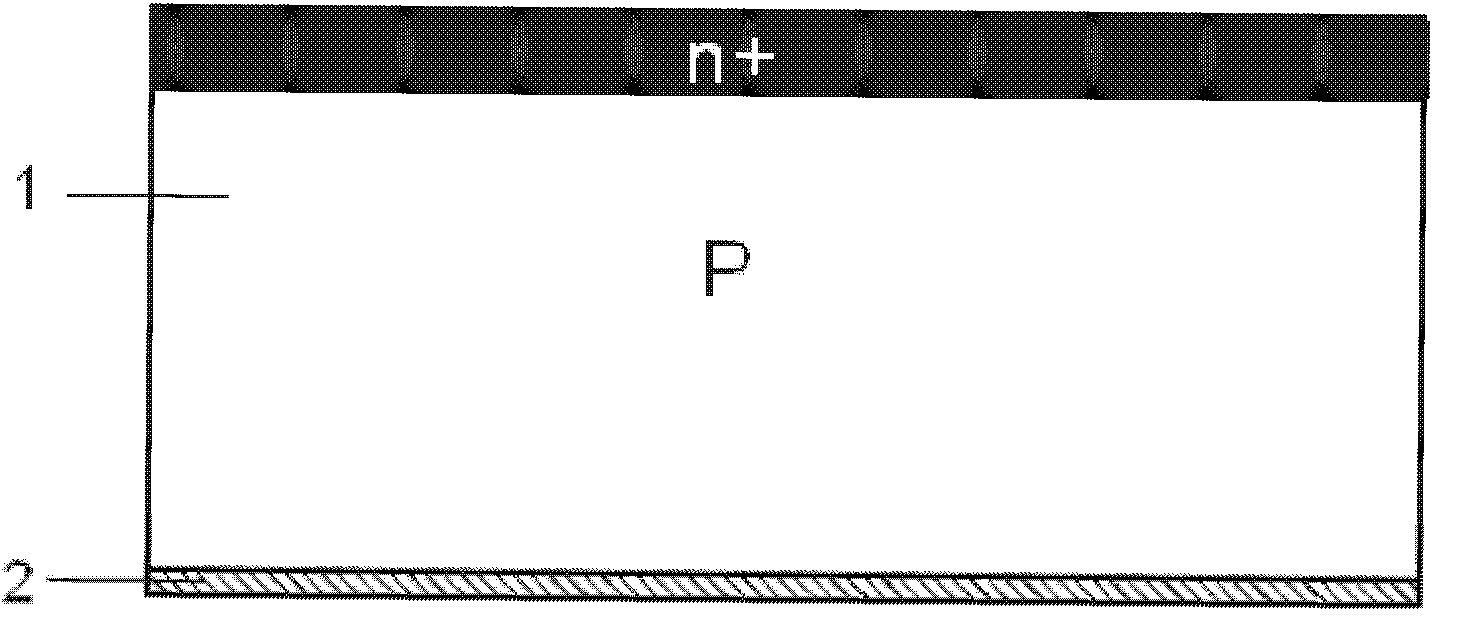

[0031] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0032] The following takes a P-type crystalline silicon substrate as an example to describe how to realize the structure of the present invention by using the improved pulse laser annealing process. Because the structure of the present invention is only aimed at the formation of back passivation and back electrode, described embodiment only introduces the specific process realization of forming solar cell back passivation and back electrode, the P-N emitter electrode, SiNx anti-reflection film and front side of solar cell front The electrode part can be realized with conventional crystalline silicon solar cell technology. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com