Nano-spraying electrode as well as manufacturing method and application thereof

A production method and nano-spray technology, applied in the field of analytical chemistry, can solve the problems of cumbersome production process, unstable spray, short service life, etc., and achieve the effects of improving mass spectrometry sensitivity, reducing detection limit and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

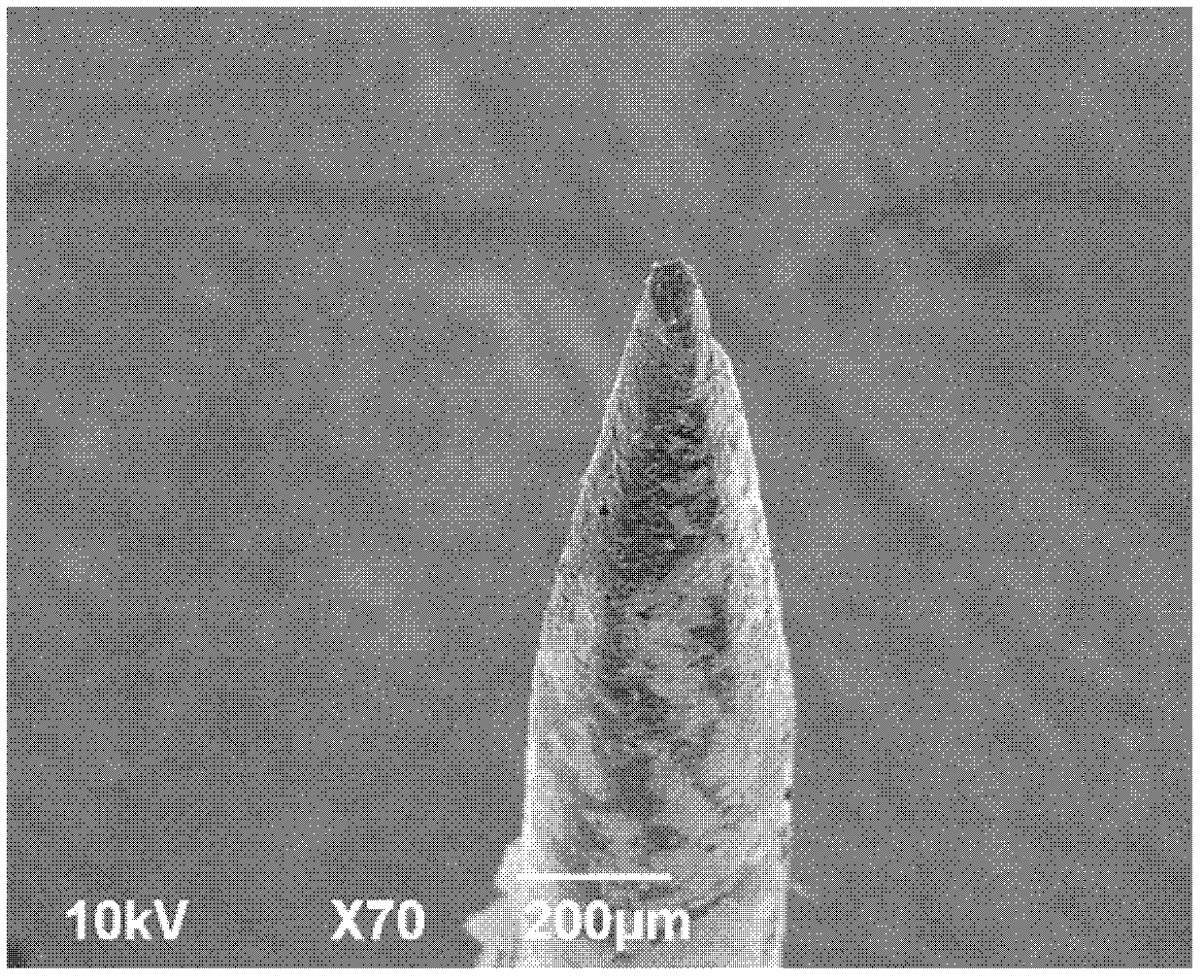

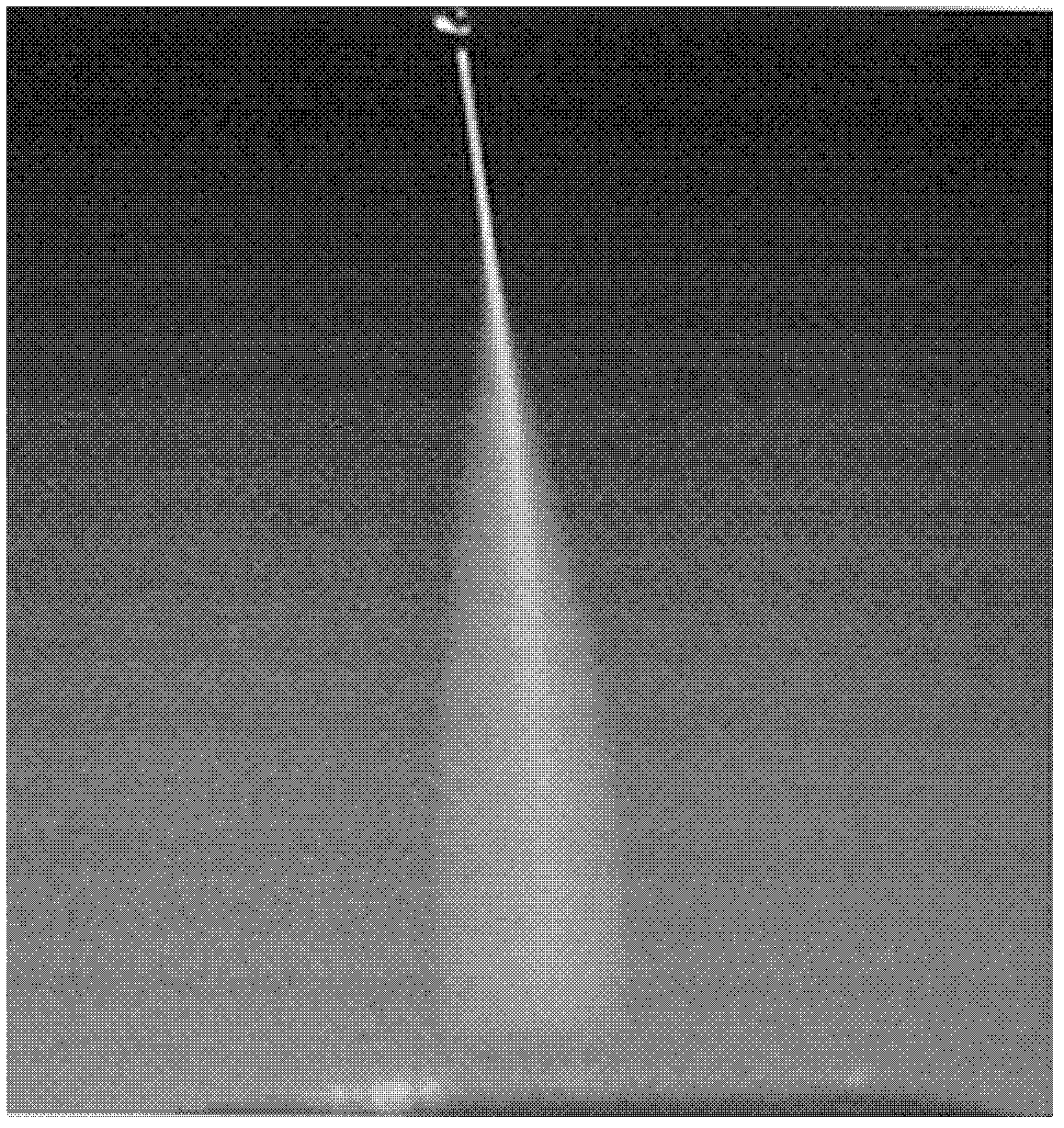

[0038] One, make the nanospray electrode of the present invention

[0039] a) Make the tip of the quartz capillary needle: cut off a quartz capillary with a length of 10-11 cm and an inner diameter of 50 μm, burn off the polyimide coating at one end for about 0.3-0.5 cm, and remove the polyimide coating with sandpaper One end of the capillary was ground into a symmetrical tip; then the tip was soaked in ethanol to remove the silicon particles on the tip, and placed for later use;

[0040] b) Making a conductive coating: cut the gold foil so that it is 1-2cm long and 0.1-0.3cm wide, and the thickness of the gold foil can be 0.1-8μm, preferably 0.12μm; pass the cut gold foil through the epoxy resin Adhered to the tip of the quartz capillary needle;

[0041] c) feed water or an organic solvent into the quartz capillary needle, and check whether the outlet is blocked to ensure that the tip is not blocked; the recommended organic solvent is methanol, acetonitrile or acetone, prefe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com