Supercritical steam oxidization test device

An oxidation test, water vapor technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of cost increase, high-pressure pipeline stress corrosion, high cost, etc., achieve manufacturing difficulty and cost reduction, high temperature control accuracy, uniformity Tropical wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

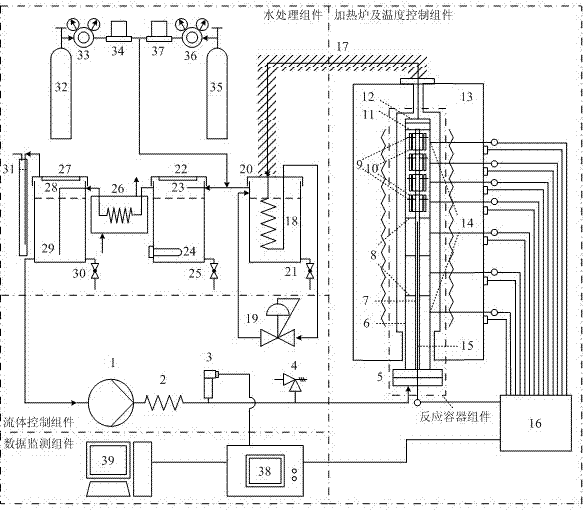

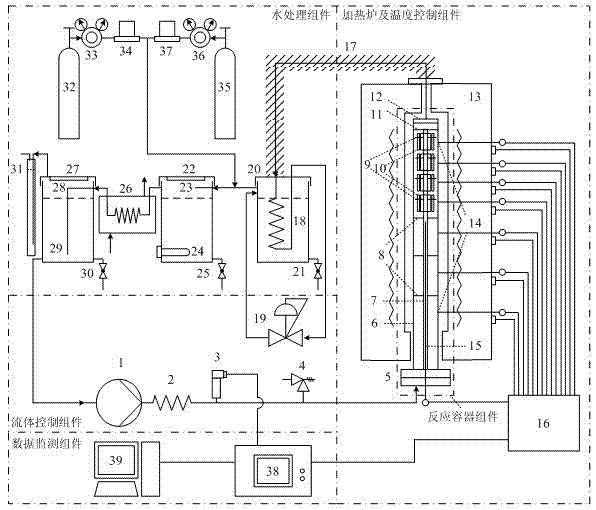

[0026] Such as figure 1 As shown, a supercritical water vapor oxidation test device provided by the present invention includes five parts: a fluid control assembly, a reaction vessel assembly, a heating furnace and a temperature control assembly, a water treatment assembly, and a data monitoring assembly, wherein the fluid control assembly, the reaction vessel assembly It is connected with the water treatment components through stainless steel pipes and pipe joints to form a medium circulation loop.

[0027] The fluid control components include: high-pressure metering pump 1, which can be selected according to the test requirements. Generally, the maximum working pressure > 30MPa, the maximum flow rate > 10L / h, the pump outlet is equipped with a damping mechanism, which is the damper 2; the back pressure valve 19, adjust And stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com