A thermodynamic cycle system using carbon dioxide as a cycle working medium

A circulating working medium and heater technology, which is applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as poor thermodynamic properties, low waste heat recovery rate, flammability, etc., achieve good thermodynamic properties, and improve waste heat utilization rate, the effect of reducing the lower limit of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the accompanying drawings.

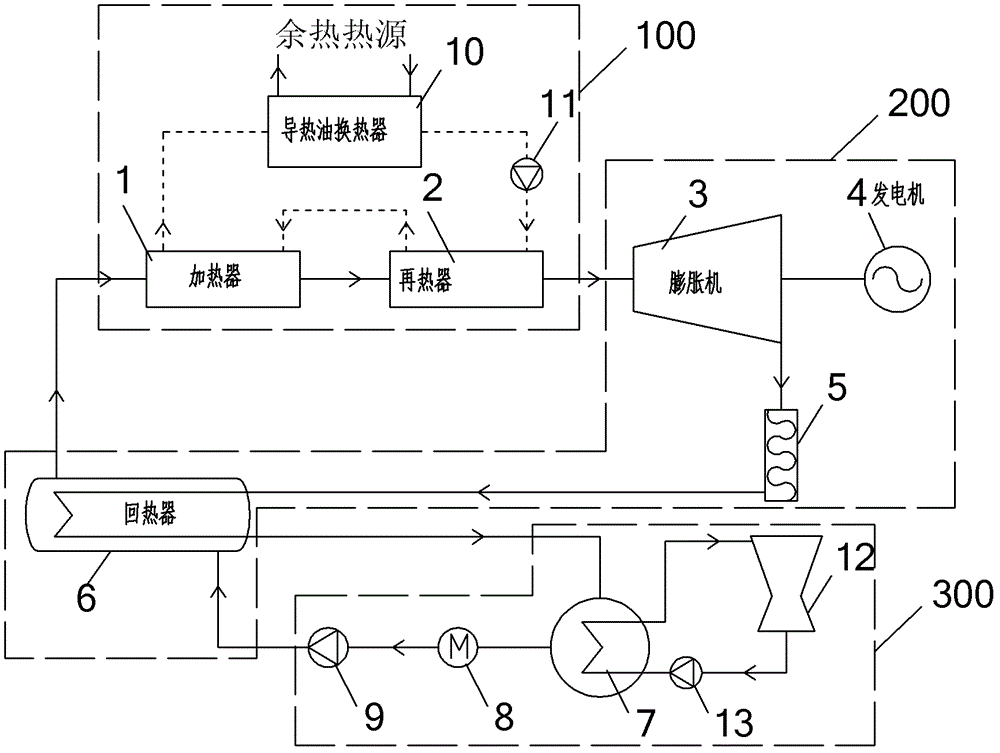

[0013] Such as figure 1 Shown, the present invention is a kind of utilization CO 2 As a thermal cycle system for circulating working fluid, it is installed in the low-temperature waste heat environment widely present in the industrial field. Heater 1, heater 2, heat transfer oil heat exchanger 10 and heat oil pump 11 form heat recovery module 100, expander 3, generator 4, lubricating oil separation device 5 and regenerator 6 form expansion power generation module 200, condenser 7. A flow controller 8 , a working medium pump 9 , a cooling water tower 12 and a cooling water pump 13 form a condensation module 300 .

[0014] Heater 1, heater 2, expander 3, and lubricating oil separation device 5 are connected to the condenser 7 through the tube (shell) side of the regenerator 6, and the condenser 7, flow controller 8, and working medium pump 9 are reheated The shell (pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com