Oilfield oil sludge treatment method

A technology of sludge and oil sludge, which is applied in the direction of sludge treatment, mining wastewater treatment, chemical instruments and methods, etc., and can solve the problems of sludge pollution and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

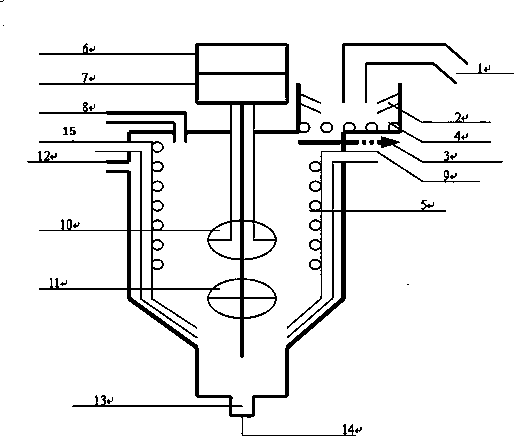

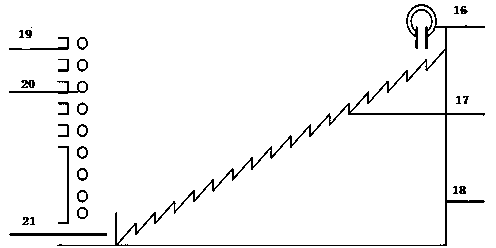

Image

Examples

Embodiment 1

[0032] 1) Select the landed oil sludge in the oil production area of Karamay Oilfield, which is semi-solid and dark brown, with no obvious crude oil accumulation condensate, crude oil and soil are closely attached, and the oil sludge contains 14.30% oil, 34.60% water, and the rest is solid matter .

[0033] 2) Using screw feeder, according to 4m 3 Feed rate per hour pushes the viscous sludge into the hot and high-pressure jet water injection basket, and removes iron metal at the same time. Conditions: heating temperature 90°C, stirring time 60min, solid-liquid ratio 1:4, chemical concentration respectively 0.5% w / w demulsifier, 1.0% w / w gel breaker, 10% w / w organic solvent, start stirring and washing, after heating, medicament, degreasing, aeration homogenization, centrifugal separation and natural sedimentation combined process , The sand content rate in the recovered oil liquid is 0.4%, the oil content rate in the mud sand is 0.3%, and the water content rate in the oil is...

Embodiment 2

[0035]1) The selected oil sludge from Fengcheng Oil Production Plant of Karamay Oilfield is semi-fluid, dark brown, with obvious crude oil accumulation condensate, oil content is 51.30%, water content is 9.25%, and the rest is solid matter. Because the oil sludge comes from the heavy oil production area, it has high content of asphaltene and colloid, and its appearance is relatively viscous and semi-fluid.

[0036] 2) Using screw feeder, according to 4m 3 Feed rate of / h pushes the viscous sludge into the hot and high-pressure jet water injection basket, and at the same time carries out metal adsorption and removal. Conditions: heating temperature is 90°C, stirring time is 80min, solid-liquid ratio is 1:5, and the concentrations of chemicals are respectively Demulsifier 1.0% w / w, gel breaker 1.5% w / w, organic solvent 15% w / w, start stirring and washing, after heating, medicament, degreasing, aeration homogenization, centrifugal separation and natural sedimentation combined pro...

Embodiment 3

[0038] 1) The selected sludge from the No. 5 Oil Production Plant of Karamay Oilfield contains 13.60% oil, 20.25% water, and the rest is solid matter. This sludge is aged sludge stored in the oilfield for a long time, so the content of asphaltene and colloid is high, and there is almost no light component.

[0039] 2) Using screw feeder, according to 4m 3 Feed rate of / h pushes the viscous sludge into the hot and high-pressure jet water injection basket, and at the same time carries out metal adsorption and removal. Conditions: heating temperature 95°C, stirring time 90min, solid-liquid ratio 1:6, chemical concentration respectively Demulsifier 1.2% w / w, gel breaker 2.0% w / w, organic solvent 15% w / w, start stirring and washing, after heating, medicament, degreasing, aeration homogenization, centrifugal separation and natural sedimentation combined process, The recovered oil has a sand content of 0.8%, an oil content of 2.0% in mud and sand, and a water content of 2.0% in oil. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com