Carbon-carrying core-shell type platinoid-platinum catalyst for indirect electrolytic hydrogen production and preparation method thereof

A platinum catalyst and core-shell technology, which is applied in the field of carbon-supported core-shell platinum-copper-platinum catalyst for indirect electrolysis hydrogen production and its preparation, can solve the problems of complicated operation process, inability to effectively improve catalytic efficiency, etc., and achieve high catalytic performance. The effect of activity, small particle size, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

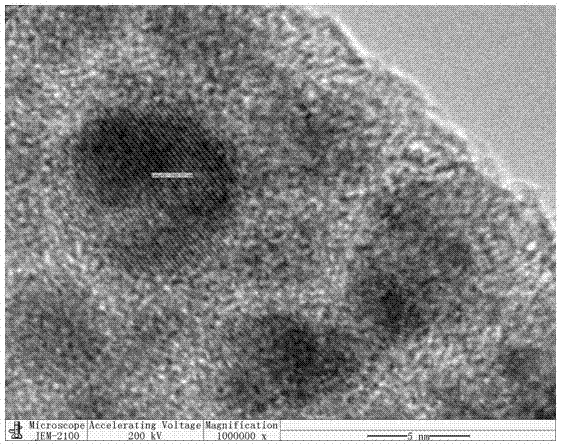

Image

Examples

Embodiment 1

[0031] A. Plain acrylonitrile graphite cloth with a surface density of 0.20g / cm 2 The graphite fiber cloth is the carbon carrier, the size is 40×40mm 2 The graphite fiber cloth was ultrasonically cleaned with analytical pure acetone for 15 minutes, and then cleaned at 7×10 -3 In a vacuum environment of Pa, ion beam cleaning is carried out to obtain a clean and activated fresh surface. Finally, ion beams are used to bombard platinum targets embedded with several small copper targets, and PtCu particles are deposited on the surface of graphite fiber cloth to prepare carbon-supported nanocrystalline films. Catalyst (PtCu / C);

[0032] B. Place the carbon-supported nanocrystalline thin film catalyst (PtCu / C) obtained in step A in H2 with a mass concentration of 0.50mol / L 2 SO 4 Soak in the solution until the carbon-supported nanocrystalline thin film catalyst is covered, the soaking temperature is 50°C, and the soaking time is 10 minutes;

[0033] C. After the catalyst treat...

Embodiment 2

[0037] A. Plain acrylonitrile graphite cloth with a surface density of 0.20g / cm 2 The graphite fiber cloth is the carbon carrier, the size is 40×40mm 2 The graphite fiber cloth was ultrasonically cleaned with analytical pure acetone for 15 minutes, and then cleaned at 7×10 -3 In a vacuum environment of Pa, ion beam cleaning is carried out to obtain a clean and activated fresh surface. Finally, ion beams are used to bombard platinum targets embedded with several small copper targets, and PtCu particles are deposited on the surface of graphite fiber cloth to prepare carbon-supported nanocrystalline films. Catalyst (PtCu / C);

[0038] B. Place the carbon-supported nanocrystalline thin film catalyst (PtCu / C) obtained in step A in H2 with a mass concentration of 0.75mol / L 2 SO 4 Soak in the solution until the carbon-supported nanocrystalline thin film catalyst is covered, the soaking temperature is 50°C, and the soaking time is 10 minutes;

[0039] C. After the catalyst treat...

Embodiment 3

[0043] A. Plain acrylonitrile graphite cloth with a surface density of 0.20g / cm 2 The graphite fiber cloth is the carbon carrier, the size is 40×40mm 2 The graphite fiber cloth was ultrasonically cleaned with analytical pure acetone for 15 minutes, and then cleaned at 7×10 -3 In a vacuum environment of Pa, ion beam cleaning is carried out to obtain a clean and activated fresh surface. Finally, ion beams are used to bombard platinum targets embedded with several small copper targets, and PtCu particles are deposited on the surface of graphite fiber cloth to prepare carbon-supported nanocrystalline films. Catalyst (PtCu / C);

[0044] B. Place the carbon-supported nanocrystalline thin film catalyst (PtCu / C) obtained in step A in H2 with a mass concentration of 1.00mol / L 2 SO 4 Soak in the solution until the carbon-supported nanocrystalline thin film catalyst is covered, the soaking temperature is 50°C, and the soaking time is 10 minutes;

[0045] C. After the catalyst treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com