Magnesium oxide for magnesium phosphate concrete, preparation method of magnesium oxide and magnesium phosphate concrete

A technology of magnesium phosphate cement and magnesium oxide, which is applied in the field of medical biomaterials to achieve the effect of enhancing adhesion, ensuring stability and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 magnesium oxide preparation

[0041] In the following examples 1-6, the magnesia used is a mixture of two magnesia with different reactivity at different calcination temperatures, and the reactivity of magnesia calcined at high temperature is lower than that of magnesia calcined at low temperature.

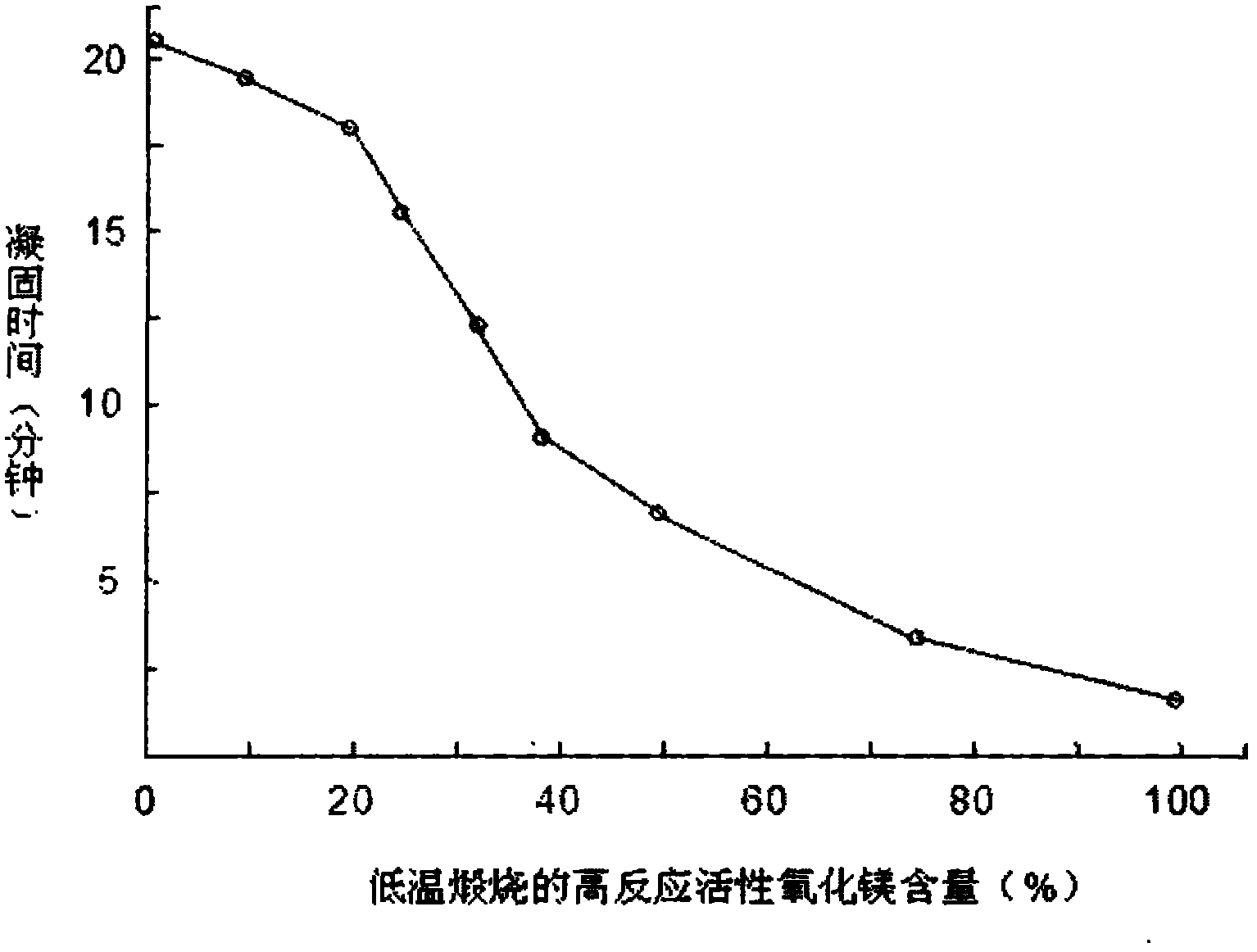

[0042] Taking the calcining temperature as 1300 DEG C and 1600 DEG C as raw materials, the preparation method is specifically described: (1) first determine the target setting time of cement according to the requirements of magnesium phosphate cement. The time is determined to be 8 minutes, and then two kinds of magnesia with different reactivity at different calcination temperatures are used: one is calcination temperature of 1300°C and calcination time of 2 hours, the other is calcination temperature of 1600°C, and the calcination temperature is 1600°C. The burning time is 5 hours. Among them, the setting time of cement obtained by using magnesium oxide calc...

Embodiment 2

[0044] Magnesium phosphate cement powder composition (mass percentage): magnesium oxide 45%; potassium dihydrogen phosphate 41%; sodium dihydrogen phosphate 3%; magnesium dihydrogen phosphate 1%; hydroxyapatite 5%; calcium sulfate hemihydrate 2% ; Sugar additives 2%, of which sucrose accounts for 90%, dextran (70,000 molecular weight) accounts for 10%; glutamic acid 1%.

[0045] According to the ratio of 10:2.5 (mass volume ratio, g / ml), mix the powder and activator water, stir into a paste, for injection or direct use.

Embodiment 3

[0047] Magnesium phosphate cement powder composition (mass percentage): magnesia 30%; potassium dihydrogen phosphate 58%; sodium dihydrogen phosphate 1%; hydroxyapatite 2%; calcium sulfate hemihydrate 5%; sugar additives 3.5% , wherein sucrose accounts for 85%, dextran (70,000 molecular weight) accounts for 15%; glutamic acid 0.5%.

[0048] According to the ratio of 10:2.5 (mass volume ratio, g / ml), mix the powder and water, stir into a paste, for injection or direct use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com