Biological deoxidation denitrification method in oxidative environment groundwater and device thereof

A technology for oxidizing environment and groundwater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of simple operation, low cost, economy and environmental protection advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

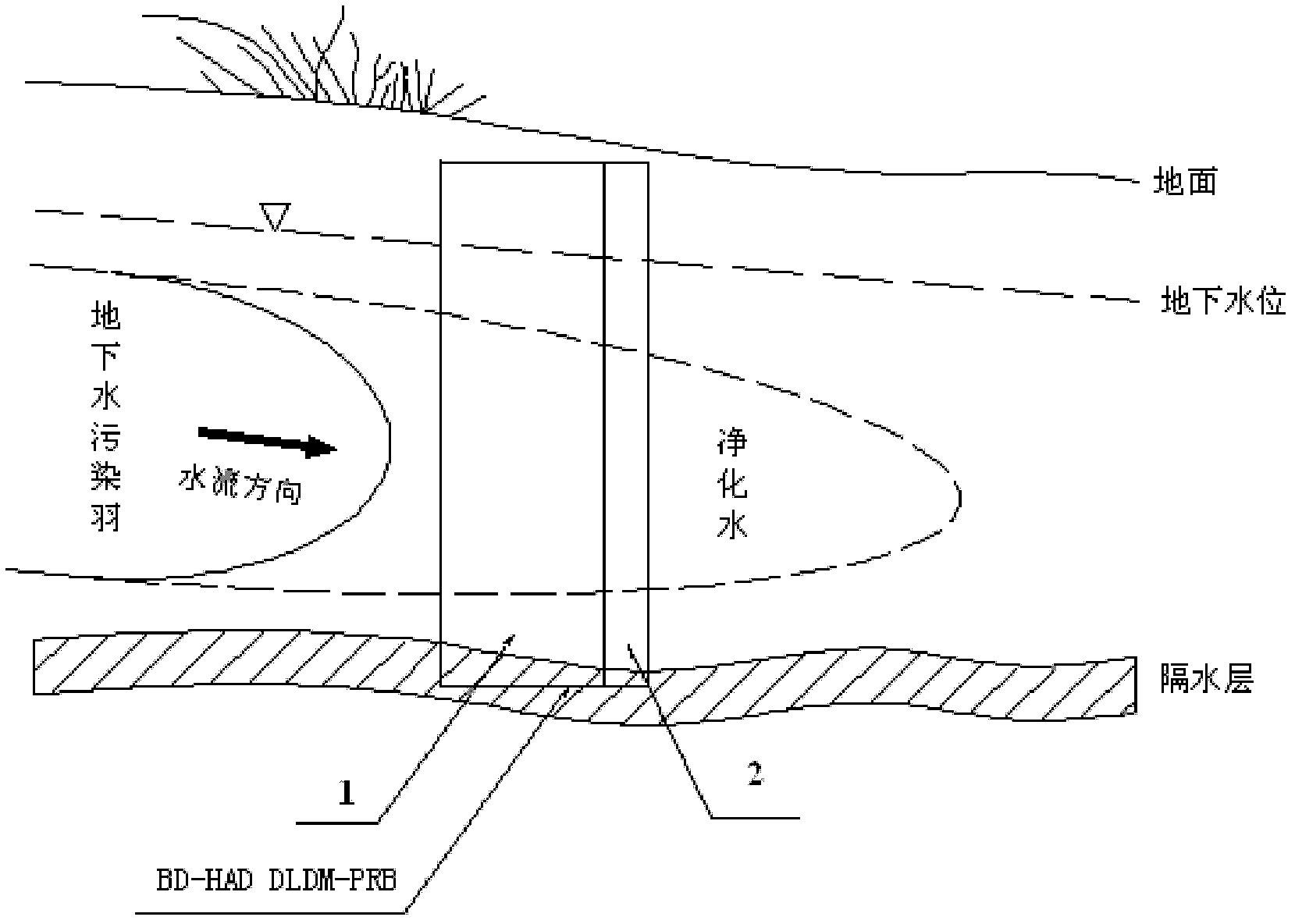

[0070] Example 1 Biological Oxygen Removal and Denitrification Device for Groundwater in Oxygenating Environment

[0071] Such as figure 1As shown, the biological deoxygenation and denitrification device for groundwater in an oxidative environment of the present invention is a double-layer double-media osmotic reaction grid, which is composed of an upstream layer 1 and a downstream layer 2. Pine bark is added in the upstream layer 1, and pine bark is added in the downstream layer. Add zero-valent iron and sand to layer 2. The particle size of pine bark is 2.0-11.0mm. Zero-valent iron can be sponge iron, whose Fe 0 The content is >60.6%, and the particle size is 0.15-2.0mm. The sand particles can be natural river sand with a particle size of 0.45-2.0 mm. The function of the sand particles is to prevent the sponge iron plates from agglomerating and maintain the hydraulic conditions of the downstream layer unchanged. The masses of pine bark, sponge iron and sand grains are 7....

Embodiment 2

[0072] Static domestication and enrichment of embodiment 2 microorganisms

[0073] 2.1 Materials and Instruments

[0074] Pine bark: industrial grade, particle size 2.0~11.0mm, BET=0.46m 2 / g, Purchased from Beijing Zhongshu Dalin Flower Market;

[0075] Sponge Iron: Industrial Grade, Fe 0 >60.6%, the main impurity is SiO 2 , with a particle size of 0.15-2.0 mm, purchased from Beijing Kaibiyuan Co., Ltd.;

[0076] Sand: natural river sand with a particle size of 0.45-2.0mm;

[0077] NaHCO 3 : Beijing Chemical Plant (analytical pure);

[0078] NaNO 3 : Shantou Xilong Chemical Co., Ltd.;

[0079] K 2 HPO 4 : Beijing Fine Chemical Co., Ltd.;

[0080] Wide Mouth Frosted Jar (20L).

[0081] Microbial inoculum source: the inoculum source of aerobic heterotrophic bacteria, heterotrophic denitrification bacteria and autotrophic denitrification bacteria was taken from the soil in the corn field in the suburbs of Beijing (0.3m below the ground), with a particle size of 0.1...

Embodiment 3

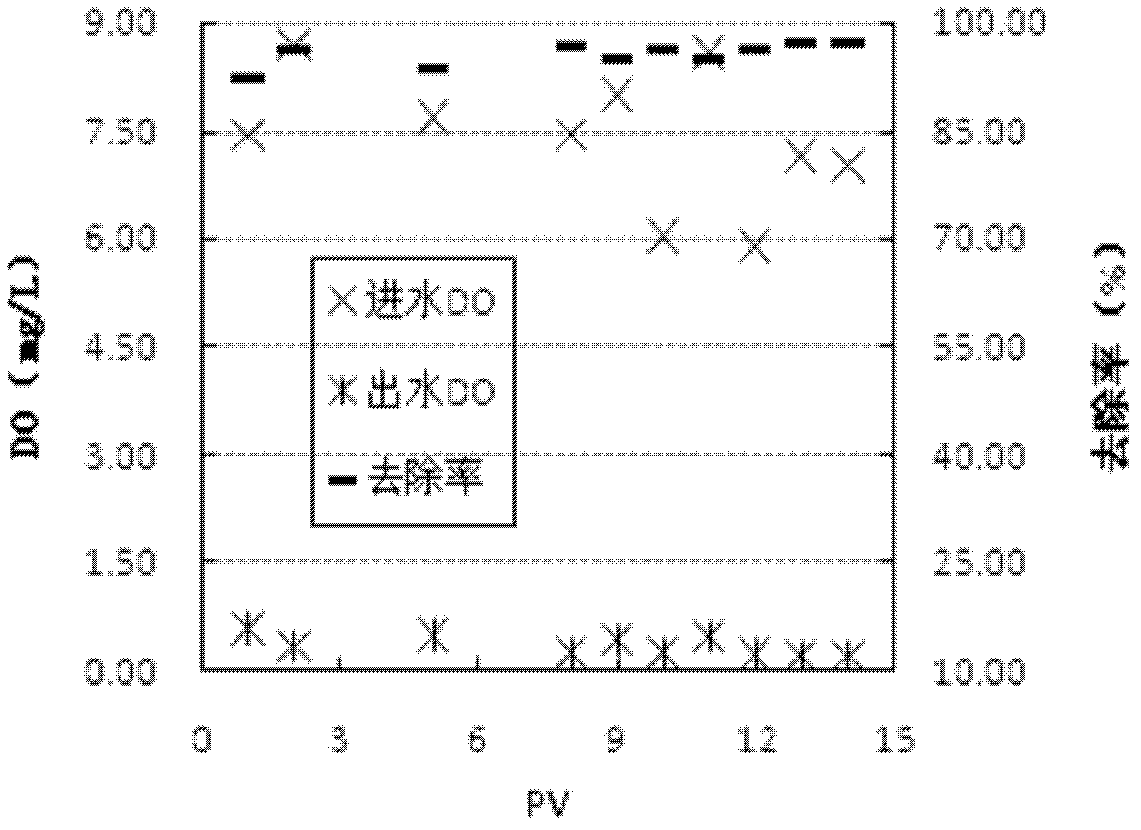

[0091] Example 3 Preparation of Biological Oxygen Removal-Heterotrophic / Autotrophic Denitrification Double-layer Dual-Media Osmotic Reaction Grid (BD-HAD DLDM-PRB) and Its Effect on DO and NO in Groundwater 3 -N removes the application

[0092] 3.1 Materials and instruments

[0093] Pine bark: industrial grade, particle size 2.0~11.0mm, BET=0.46m 2 / g, Purchased from Beijing Zhongshu Dalin Flower Market;

[0094] Sponge iron: industrial grade, particle size 0.15-2.0mm, Fe 0 >60.6%, the main impurity is SiO 2 , BET=0.49m 2 / g, Purchased from Beijing Kaibiyuan Co., Ltd., the particle size is 0.15-2.0mm;

[0095] Sand: natural river sand with a particle size of 0.45-2.0mm.

[0096] 3.2 Preparation of BD-HAD DLDM-PRB

[0097] 1) For sieving pine bark, the selected particle size is 2.0-11.0mm; for sieving sponge iron, the selected particle size is 0.15-2.0mm; for sieving sand, the selected particle size is 0.45-2.0mm.

[0098] 2) Weigh the pine bark, sponge iron and san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com