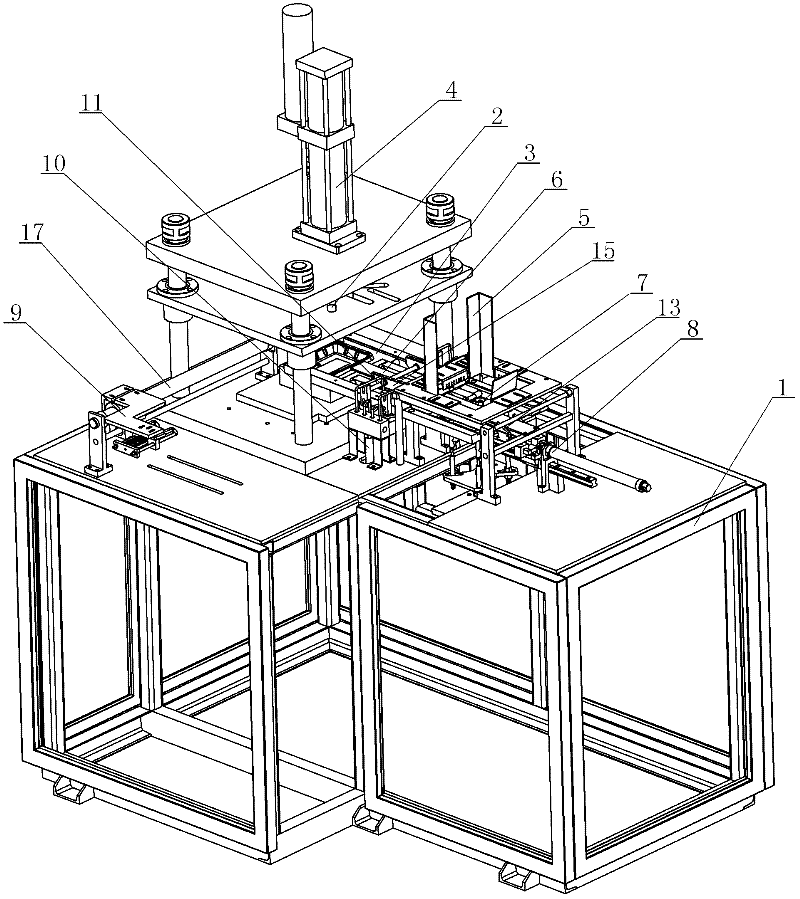

Fully-automatic paper plate or meal box forming machine

A fully automatic, forming machine technology, applied in the direction of cardboard items, etc., can solve the problems of insufficient feeding and disorderly output, and achieve the effects of high pass rate, neat stacking, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

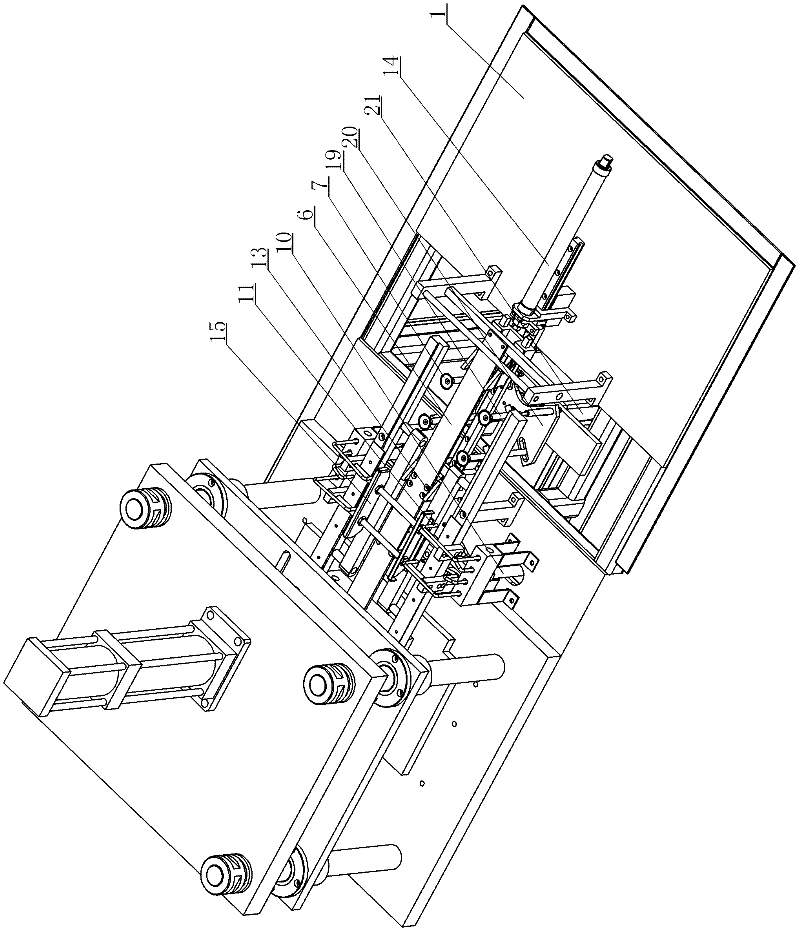

[0019] Depend on figure 1 combine Figure 2-Figure 5 As shown, the fully automatic paper dish lunch box forming machine includes a frame 1, an upper mold 2 and a lower mold 3 are installed on the frame 1, the upper mold 2 is driven by a booster cylinder 4 fixed on the frame 1, and the frame 1 is provided with a cardboard warehouse 5 and a platform 6, the platform 6 is located under the cardboard warehouse 5 and leads to the lower mold 3, and the vacuum suction cup 7 with linear lifting movement is arranged under the cardboard warehouse 5. The vacuum suction cup 7 is made of rubber material, and the vacuum suction cup 7 is pasted. After the cardboard is pressed, the internal air is extruded, and a vacuum is formed inside the vacuum suction cup 7 to suck the cardboard. The frame 1 is provided with a linear reciprocating cardboard propulsion device 8, and the cardboard propu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com