Method and device for extruding continuous long glass fibers

A long glass fiber, square technology, applied in the field of polymer processing methods and devices, can solve the problems of affecting the quality of extrusion, uneven distribution of glass fiber, difficulty in glass fiber extrusion, etc., to improve production efficiency, easy to implement, Create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention: a method for realizing the continuous long glass fiber extrusion, extruding the continuous long glass fiber and the plastic matrix through the mold of the independent flow channel, during the extrusion process, the continuous long glass fiber is formed in the independent flow channel It advances in the form of a sine wave, and finally extrudes through a die, so that the continuous long glass fibers are evenly distributed in the product.

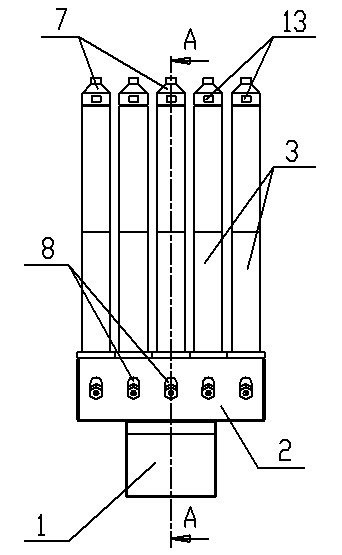

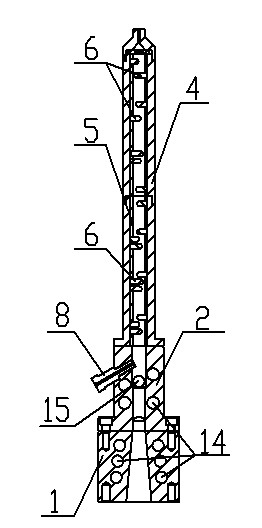

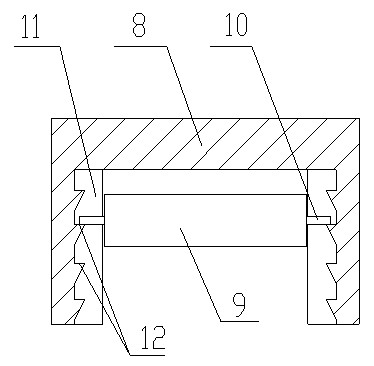

[0020] The structure of the device for continuous long glass fiber extrusion is as follows: figure 1 As shown, including the base 1, the hot runner 2 is connected to the base 1, and the heating pipe 14 is provided in the side walls of the base 1 and the hot runner 2; The feed inlet 8 is connected with more than one independent flow channel 3 at the front end of the hot runner 2; the independent flow channel 3 includes a cylindrical self-heating outer shell 4 (the processing of the self-heating outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com