Ultra fast cooling and conventional laminar flow cooling method for medium plate

An ultra-fast cooling and laminar cooling technology, applied in the field of metallurgy, can solve the problems of difficult to control the shape of the steel plate, difficult to correct the shape of the steel plate, difficult to produce medium and thick plates, etc., to achieve good process performance, improve cooling speed, and adjust flexibly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

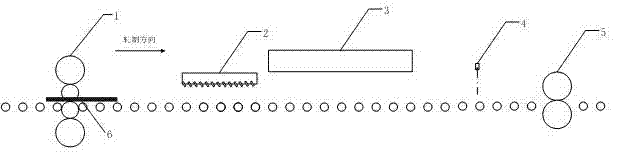

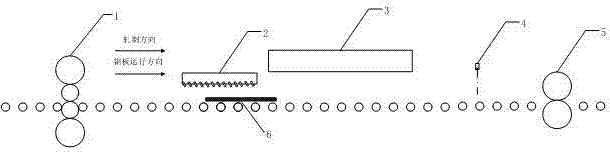

[0035] Straightening first and then forward cooling method: to produce EH36 ship plate with a thickness of 40mm, using attached figure 1 The deployed equipment implements straightening first and then forward cooling technology, which is characterized by the use of ultra-fast cooling equipment alone. Step 1 is shown in the attachment figure 2 : Step 1: Dephosphorize the steel billet heated to 1000~1200℃, and then transport it from the conveyor roller table to the rolling mill for multiple passes to make a final-rolled medium-thick plate with a target thickness of 40mm or more. See step 2 Attached image 3 After the steel plate 6 exits the rolling mill 1, it is transported by the conveyor roller table. The rapid (at full roll speed) air cooling passes through the ultra-rapid cooling equipment 2 and the conventional laminar flow cooling equipment 3. The passing speed is the maximum roller table speed, and the two sets of water cooling equipment are not turned on. , Straightening st...

Embodiment 2

[0037] The method is basically the same as that of the above-mentioned Example 1, the difference is that the ultra-fast cooling equipment 2 is used alone to cool the 40mm thick EH36 marine steel plate 6 to 550°C, see attached Figure 5 Step 4. The cooling rate is controlled at 30°C / s, Image 6 As shown in step 5, the super fast cooling water supply pressure is also 0.5 MPa, and the steel plate 6 is transported to the cooling bed after controlled cooling. Example 2: Ultra-rapid cooling equipment 2 After straightening first and then forward cooling process, compared with the conventional laminar cooling, first straightening and then forward cooling process, the yield strength of the steel plate is increased by 8-12%, and the tensile strength is increased by 4 -6%.

[0038] Examples 1 and 2 both use ultra-fast cooling equipment alone. Example 1 "cools the steel plate to 450°C, the cooling rate is controlled at 15°C / s, and the ultra-fast cooling water supply pressure is 0.5MPa,", Exam...

Embodiment 3

[0040] Straightening first and then forward cooling method: to produce 50mm thickness EH36 ship plate, according to the attached figure 1 The shown combined arrangement of ultra-rapid cooling equipment 2 and conventional laminar flow cooling equipment 3, the steel plate 6 is heated to 1200 ℃, rolled into a steel plate with a thickness of 50 mm, see attached figure 2 Step 1: After the steel plate 6 exits the rolling mill 1, it is transported by the conveyor roller table, and the rapid air cooling passes through the ultra-rapid cooling equipment 2 and the conventional laminar flow cooling equipment 3. The two sets of water cooling equipment are not turned on, see attached image 3 Step 2. Go to the straightening machine 5 for straightening. After the straightening is completed, the drive motor of the transfer roller reverses, so that the steel plate 6 is reversed and quickly air cooled through the ultra-fast cooling device 2 and the conventional laminar flow cooling device 3, see at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com