Negative active material for lithium secondary battery and lithium secondary battery comprising same

A negative electrode active material, lithium secondary battery technology, applied in secondary batteries, lithium storage batteries, battery electrodes, etc., can solve the problems of display capacity decline, volume expansion change, short cycle life, etc., and achieve small volume expansion and large capacity. , the effect of high capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] An example of a method of manufacturing the negative electrode active material of the present invention is described below. However, the following method is only for illustrating one embodiment of the present invention, and the present invention is not limited thereto.

[0039] First, silicon and at least one metal element other than silicon are melted in an inert environment (S1).

[0040]In the method according to the present invention, any alloying element may be used for the silicon alloy as long as it can be used to manufacture an anode active material. For example, at least two elements selected from the group consisting of Sn, Zr, Mn, Ni, Fe, Ca, Ce, La, Cr, Al, Co, Sb, Bi, As, Ge, Pb, Zn, Cd can be used together , In, Ti and Ga, but not limited thereto.

[0041] When the raw material is melted, it is preferably melted under an inert environment to prevent inclusion of impurities therein.

[0042] Then, the molten liquid is powdered by a rapid solidification m...

Embodiment 1

[0060] (Manufacture of negative electrode active materials)

[0061] Metals were mixed by weights shown in Table 2 below, and melted by high-frequency heating under an argon atmosphere to produce alloy melts. By using a pressure of 80kg / cm 2 The alloy melt was quenched by gas spraying of argon gas, thereby producing alloy powder with an average diameter of about 100 μm. At this point, the quenching rate is 1×10 5 K / sec.

[0062] The obtained alloy powder was ball milled at 1000 rpm for 15 hours to produce silicon alloy powder.

[0063] (manufacturing of secondary batteries)

[0064] The obtained negative electrode active material powder was mixed with acetylene black as a conductive material and polyvinylidene fluoride (PVdF) as a binder at a weight ratio of 93:2:5, and then mixed with N-methyl-2 - Pyrrolidone (NMP) mixing to make negative electrode slurry. The obtained electrode slurry was coated on one surface of a copper current collector, dried at about 130°C for 2 hou...

experiment example 1

[0067] (Experimental example 1: measure the volume ratio of inactive phase)

[0068] It is not easy to measure the volume ratio of the inactive phase by a direct method, so it is measured and calculated according to the following procedure.

[0069] (1) Measure the density of silicon alloy

[0070] A hydrometer (AccuPyc 1340, Micromeritics Instrument Corp. USZ) was used as a device for measuring the density of the solid.

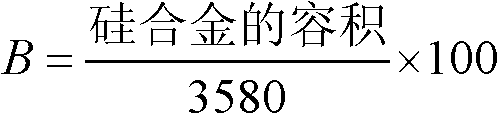

[0071] (2) Weight ratio of active phase (silicon phase) (B)

[0072] Equation 1

[0073]

[0074] (3) Weight ratio of inactive phase (C)

[0075] Equation 2

[0076] C=100-B

[0077] (4) Assume that the density of the active phase (silicon phase) is 2.33.

[0078] (5) Calculate the density (D) of the inactive phase

[0079] Equation 3

[0080]

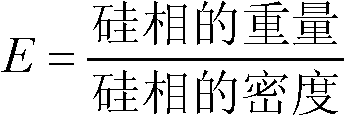

[0081] (6) Volume of active phase and inactive phase (E, F)

[0082] Here, the term "volume" refers to the volume of the active phase and the inactive phase assuming that the weight of the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com