Steel pipe water-filling pressure intensity test table

A water injection pressure and strength test technology, which is applied in the direction of applying stable tension/pressure to test material strength, using liquid/vacuum degree to measure liquid tightness, and measuring the rate of increase and deceleration of fluid, etc., can solve time-consuming, labor-intensive and economical problems Large losses, expensive advanced equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

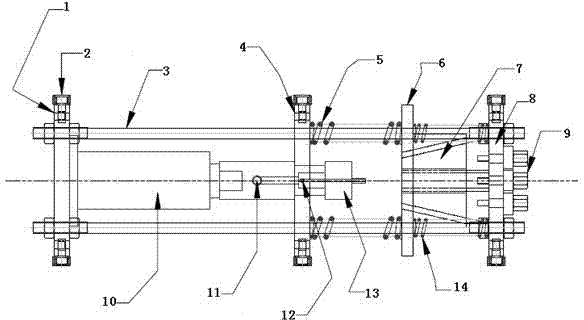

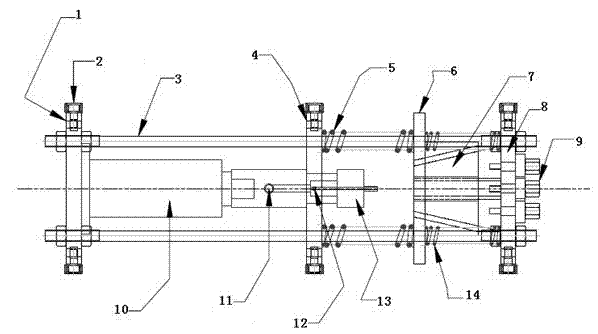

[0016] This embodiment is used in the water injection pressure strength test bench of steel pipe hydraulic pressure testing machine, the main structure is as attached figure 1 As shown, it comprises two parallel elastic sliding rails 3, and the two ends of the elastic movable rails 3 are respectively provided with a tooling positioning plate and a three-jaw self-fixing core slideway plate 8; the tooling positioning plate is provided with an oil cylinder base plate 1 and The tooling positioning mobile bearing 2; the middle part of the elastic movable road rod 3 is provided with an oil cylinder elastic movable positioning plate 4, and an elastic pressure cylinder 10 and a water pressure booster are arranged between the oil cylinder elastic movable positioning plate 4 and the tooling positioning plate, and the oil cylinder is elastically movable and positioned A three-jaw chuck moving plate 6 is provided between the plate 4 and the three-jaw self-fixing slideway plate 8; a positiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com