Drill hole vector stress sensor for mine

A stress sensor and sensor technology, applied in the field of stress sensors, can solve the problems of easy damage, time-consuming and laborious, and difficulty in determining the direction of the sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

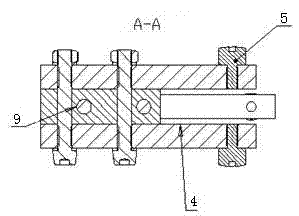

[0025] The present invention is a mine-used drilling vector stress sensor. The core adopts three balance beam sensors with an included angle of 120°, and each balance beam sensor is equipped with a 1cm 2 The force-measuring nut, and the electronic compass part is added in the circuit, the maximum principal stress and direction, the minimum principal stress and direction on a certain plane can be calculated, and remote transmission can be carried out, which solves the problem that the sensor core in the prior art is easy to Technical problems such as damage, single measurement direction, and unextractable data.

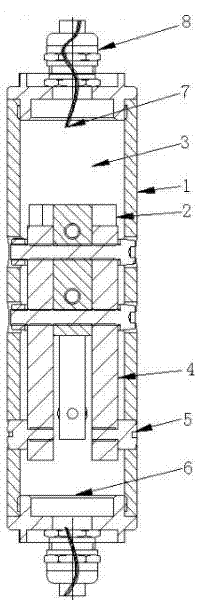

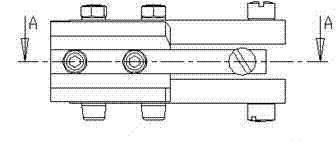

[0026] see figure 1 The vector stress sensor for mine drilling is composed of three parts: integrated circuit module 3, core body 2 and shell 1. The model of integrated circuit module 3 is MSP430F149. Potting and sealing to protect internal measurement components and integrated circuits from external influences. The outer casing 1 is made of stainless steel to protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com