Anti-cracking steel-concrete combined continuous girder bridge of negative moment region

A negative moment area, concrete technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of insufficient tensile and shear resistance, low crack resistance in negative moment areas, and large amount of structural steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] At present, there is no steel-concrete composite continuous girder bridge with crack resistance in the negative moment zone at home and abroad.

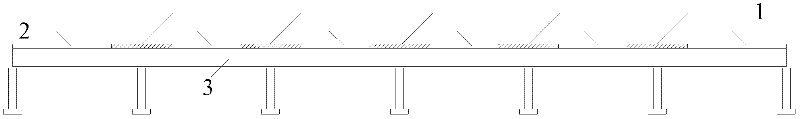

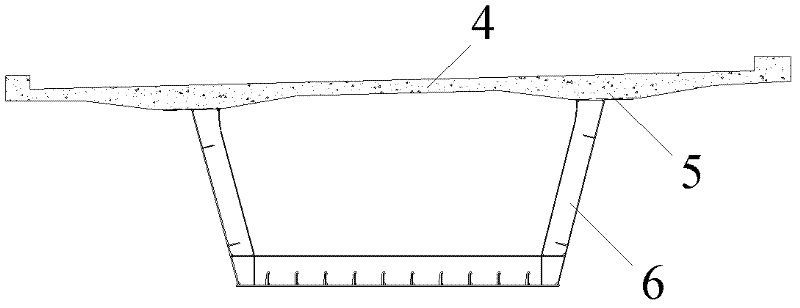

[0036] This example proposes a crack-resistant steel-concrete composite continuous girder bridge in the negative moment zone. The main girder adopts a channel-shaped steel structure, and the bridge deck is a concrete structure. Structural facade layout see figure 1 , the cross-sectional arrangement shows figure 2 , where the section type of the channel steel girder is variable, that is, the type and quantity of the channel box chamber, the top plate, the web and the bottom plate of the channel steel girder can be provided with stiffeners, diaphragms or transverse ribs. The channel-shaped steel main girder structure and shear studs are made of high-quality standard steel; the bridge deck is made of two kinds of concrete materials, and the base material in the negative moment area of the bridge deck is made of dry apparent den...

Embodiment 2

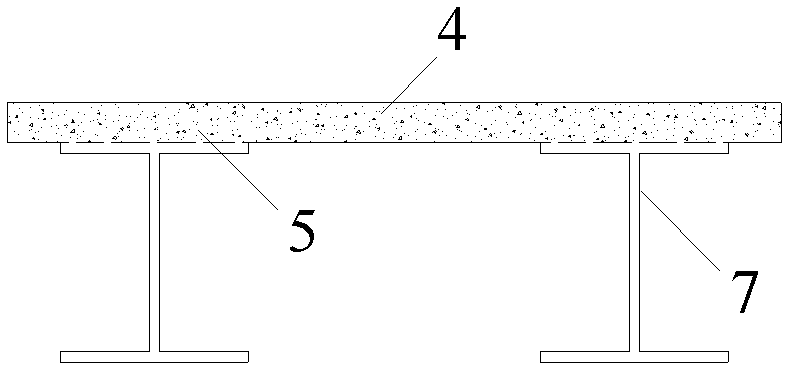

[0052] This example proposes a crack-resistant steel-concrete composite continuous girder bridge in the negative moment zone. Structural facade layout see figure 1 , the cross-sectional arrangement shows image 3 . Among them, the section type of the I-beam main beam structure can be changed, that is, the type and quantity of the I-beam, the top plate, the web plate and the bottom plate of the I-beam main beam can be provided with stiffeners, diaphragms or transverse ribs. The I-beam main girder structure and shear studs are made of high-quality standard steel; the bridge deck is made of two kinds of concrete materials, and the base material in the negative moment area of the bridge deck is made of dry apparent density not less than 2400kg / m 3 High-strength organic polymer fiber concrete, high-strength organic polymer fiber concrete has high tensile strength and high shear strength (more than 20% higher than high-strength ordinary concrete), and prestressed steel bars are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com