Coating method for reinforcing high silica glass fiber fabric

A high-silica glass fiber and glass fiber technology, applied in fiber treatment, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of many equipment, complex process flow, unfavorable industrial production, etc., to simplify process steps, improve Mechanical properties and the effect of improving high temperature antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh 61.83 grams of boric acid, 119.35 grams of triethanolamine and 422.75 grams of ethanol, and prepare a solution;

[0029] 2) Immerse the high-silica glass fiber fabric in an ethanol solution for surface coating for 1 minute, and dry it at 80°C;

[0030] 3) heat-treating the high-silica glass fiber-coated fabric for 1 hour under a nitrogen flow at a temperature of 160°C;

[0031] 4) heat-treating the high-silica glass fiber-coated fabric for 1 hour at a temperature of 180° C. under nitrogen flow;

[0032] 5) In a nitrogen atmosphere and at a temperature of 350°C, heat-treat the high-silica glass fiber coated fabric for 1 hour, and obtain a reinforced high-silica glass fiber coated fabric product after cooling;

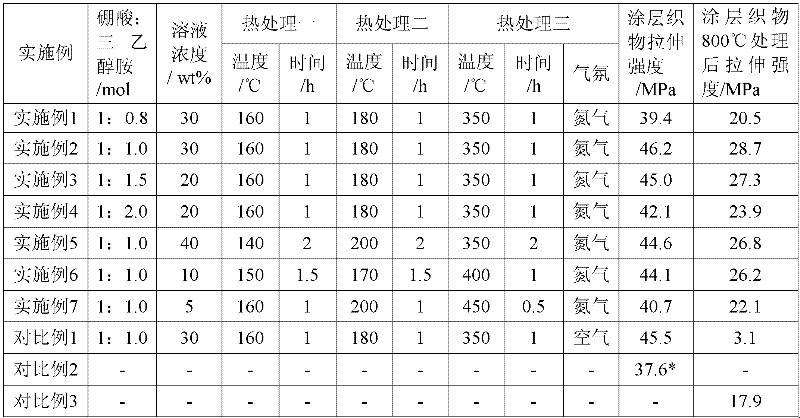

[0033] 6) test the tensile strength of the high silica glass fiber coated fabric product, the test results are shown in Table 1;

[0034] 7) Heat-treat the high-silica glass fiber coated fabric for 1 hour in an air atmosphere at a temperature of 800° C., ...

Embodiment 2

[0036] 1) Weigh 61.83 grams of boric acid, 149.19 grams of triethanolamine and 492.38 grams of ethanol, and prepare a solution;

[0037] 2) Immerse the high-silica glass fiber fabric in an ethanol solution for surface coating for 1 minute, and dry it at 70°C;

[0038] 3) heat-treating the high-silica glass fiber-coated fabric for 1 hour under a nitrogen flow at a temperature of 160°C;

[0039] 4) heat-treating the high-silica glass fiber-coated fabric for 1 hour at a temperature of 180° C. under nitrogen flow;

[0040] 5) In a nitrogen atmosphere and at a temperature of 350°C, heat-treat the high-silica glass fiber coated fabric for 1 hour, and obtain a reinforced high-silica glass fiber coated fabric product after cooling;

[0041] 6) test the tensile strength of the high silica glass fiber coated fabric product, the test results are shown in Table 1;

[0042] 7) Heat-treat the high-silica glass fiber coated fabric for 1 hour in an air atmosphere at a temperature of 800° C....

Embodiment 3

[0044] 1) Weigh 61.83 grams of boric acid, 223.79 grams of triethanolamine and 1142.48 grams of ethanol, and prepare a solution;

[0045] 2) Immerse the high-silica glass fiber fabric in an ethanol solution for surface coating for 2 minutes, and dry it at 70°C;

[0046] 3) heat-treating the high-silica glass fiber-coated fabric for 1 hour under a nitrogen flow at a temperature of 160°C;

[0047] 4) heat-treating the high-silica glass fiber-coated fabric for 1 hour at a temperature of 180° C. under nitrogen flow;

[0048] 5) In a nitrogen atmosphere and at a temperature of 350°C, heat-treat the high-silica glass fiber coated fabric for 1 hour, and obtain a reinforced high-silica glass fiber coated fabric product after cooling;

[0049] 6) test the tensile strength of the high silica glass fiber coated fabric product, the test results are shown in Table 1;

[0050] 7) Heat-treat the high-silica glass fiber coated fabric for 1 hour in an air atmosphere at a temperature of 800° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com