Method for dyeing fabric by using reactive dye and soaping fabric dyed by reactive dye, and equipment

A technology of reactive dyes and dyeing equipment, which is applied in dyeing methods, textile material processing, liquid/gas/steam textile material processing, etc., can solve the problems of upgrading and utilization of unfavorable dyeing workshops, and achieve shortening of soaping treatment time, Effects of reducing equipment power or chemical consumption and maintaining high temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

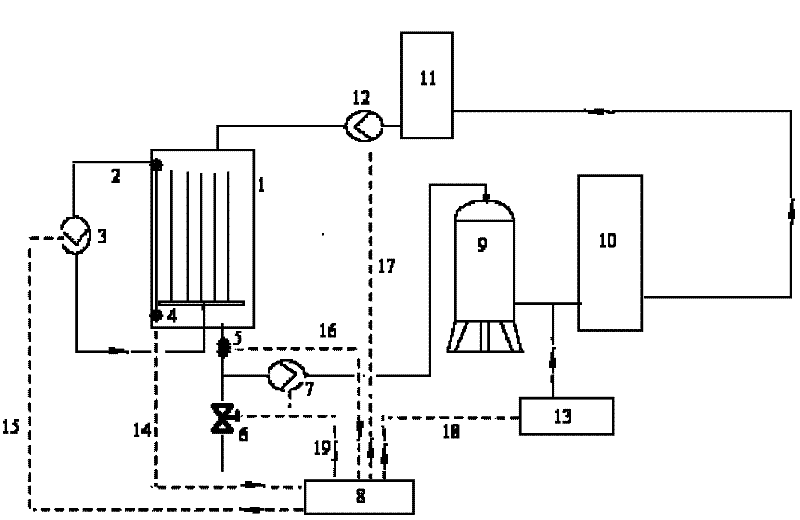

[0022] refer to figure 1 , is a device schematic diagram of a reactive dye dyeing and soaping method, which is composed of dyeing equipment arranged in series in series (consisting of cylinder body 1 in the figure, dye liquor circulation pipeline 2 and dye liquor circulation pump 3), hydrolysis dye decolorization device ( Consists of intermediate decolorization system inlet pump 7, filter 9, catalytic decolorization reaction equipment 10, decolorization liquid storage tank 11, and decolorization system outlet pump 12) to form a circulation treatment equipment, in which the dyeing equipment is reactive dye intermittent dyeing vat or continuous dyeing method The soaping water tank, the hydrolysis dye decolorization device is a high-temperature dyeing wastewater treatment device, which can be a complete set of microwave-ultraviolet photocatalytic oxidation-electrochemical combined technology. The hydrolysis dye decolorization device has a decolorization liquid storage tank, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com