Microfluidic-control preparation method for microsphere of polymethylmethacrylate-coated cadmium telluride (CdTe) quantum dot

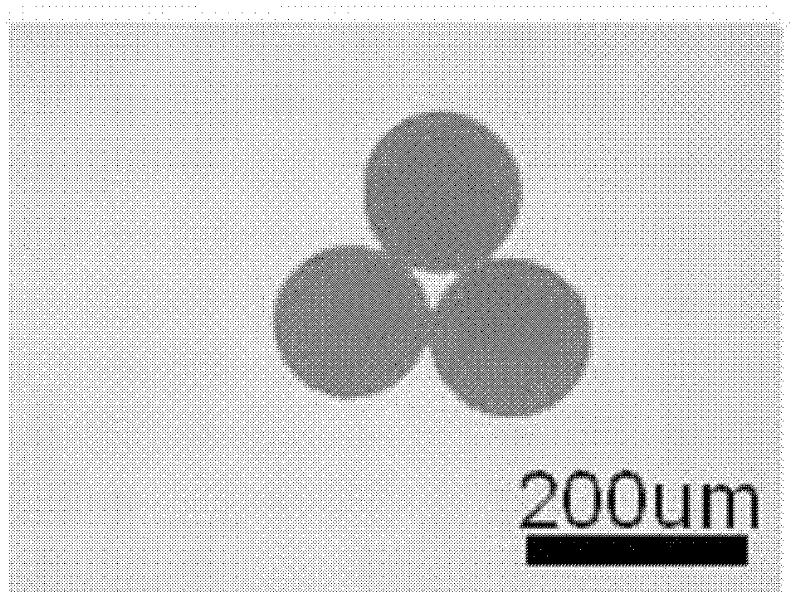

A technology of polymethyl methacrylate and quantum dots, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of quantum dot dissolution, etc., and achieve the effect of simple preparation method, long fluorescence lifetime and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

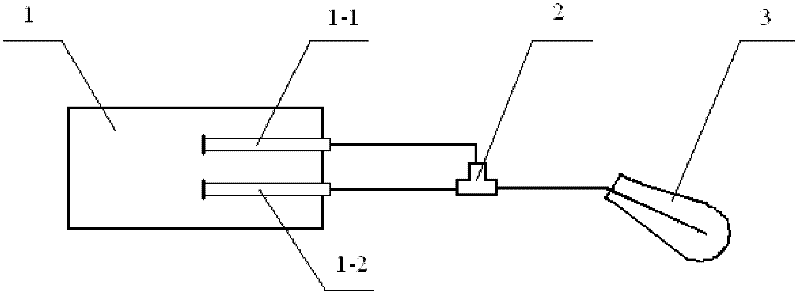

[0017] Specific embodiment 1: A microfluidic control preparation method of polymethyl methacrylate-wrapped CdTe quantum dot microbeads in this embodiment is carried out according to the following steps:

[0018] 1. Preparation of sodium tellurium hydride: Weigh sodium borohydride at a temperature of 0°C to 5 ℃ cold water and tellurium powder, first add sodium borohydride into the container, and put the container on an ice-water bath, then add the weighed cold water, then add the weighed tellurium powder, stir for 10h ~ 12h, to obtain tellurium hydride sodium solution;

[0019] Two, the preparation of cadmium telluride quantum dots: a, according to the mass volume ratio of cadmium hydroxide and N, N-dimethylformamide is 1g: 285mL~290mL, the mass volume ratio of cadmium hydroxide and lactic acid is 1g: 1.5 mL~1.6mL, the mass volume ratio of cadmium hydroxide and α-mercaptoglycerol is 1g: 1.4mL~1.5mL, the mass volume ratio of cadmium hydroxide and the sodium telluride hydride so...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the temperature of the cold water in step 1 is 1° C. to 4° C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the stirring time in step 1 is 10.5h-11.5h. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com