Large temperature difference cement slurry for cementing of deep well long isolation section and preparation method thereof

A large temperature difference, cement slurry technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of large annular flow velocity of cement slurry, increased annular flow resistance, and increased wellbore temperature difference, etc. The effect of preventing the problem of water and gas channeling, small water loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

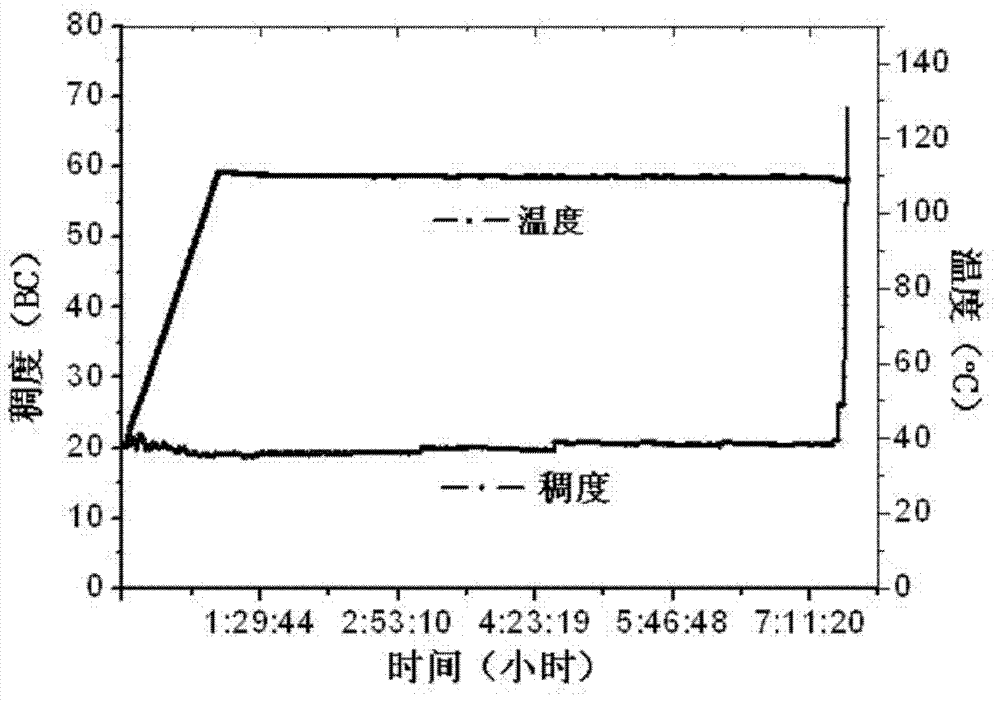

Embodiment 1

[0038] Weigh 100 parts by weight of oil well cement, 0.5 parts by weight of silica fume, 0.5 parts by weight of fly ash, 2 parts by weight of superfine cement, 0.5 parts by weight of bentonite for drilling fluid, 0.2 parts by weight of sodium silicate, 0.3 parts by weight of triethanolamine, 3 parts by weight of aluminum powder are dry mixed into a dry powder mixture. Measure 85 parts by weight of water, weigh 7 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 0.85 parts by weight of ethylenediaminetetramethylene phosphoric acid, and dissolve 0.5 parts by weight of sulfonated alkylnaphthalene formaldehyde resin in water , put the aqueous solution in the mixing container, the agitator rotates at a low speed (4000±200 rpm), and add the weighed dry powder mixture within 15 seconds, cover the lid of the agitator, and turn it at a high speed (12000±500 rpm) Min) and continue to stir for 35 seconds to obtain the cement slurry with large temperature difference for deep w...

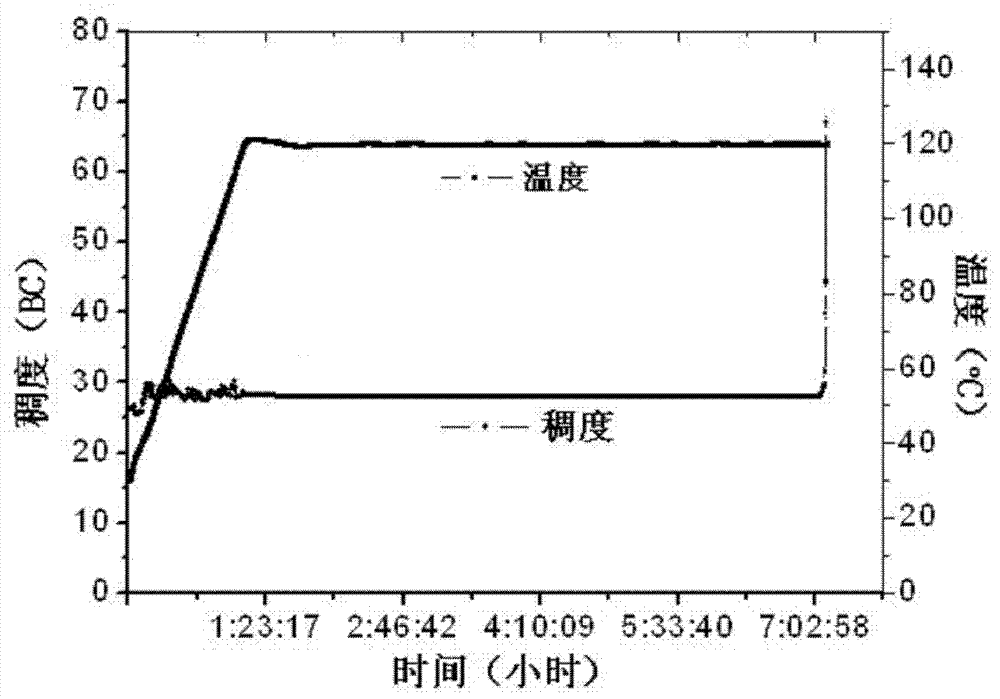

Embodiment 2

[0040] Weigh 100 parts by weight of oil well cement, 5 parts by weight of silicon powder, 1 part by weight of fly ash, 0.5 parts by weight of superfine cement, 1 part by weight of bentonite for drilling fluid, 0.5 parts by weight of sodium thiosulfate, and 0.2 parts by weight of sodium nitrate , 3 parts by weight of aluminum powder are dry mixed into a dry powder mixture. Measure 85 parts by weight of water, weigh 6.5 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 1.7 parts by weight of ethylenediamine tetramethylene phosphoric acid, and dissolve 1 part by weight of sulfonated alkylnaphthalene formaldehyde resin in water , put the aqueous solution in the mixing container, the agitator rotates at a low speed (4000±200 rpm), and add the weighed dry powder mixture within 15 seconds, cover the lid of the agitator, and turn it at a high speed (12000±500 rpm) Min) and continue to stir for 35 seconds to obtain the cement slurry with large temperature difference for the...

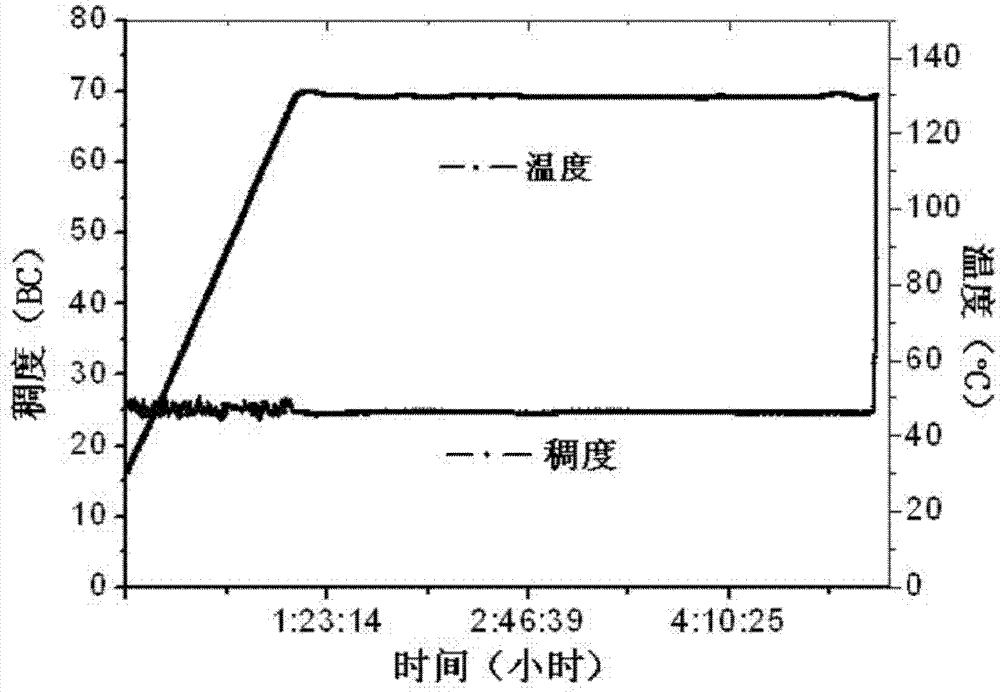

Embodiment 3

[0042] Weigh 100 parts by weight of oil well cement, 10 parts by weight of silicon powder, 0.5 parts by weight of fly ash, 5 parts by weight of superfine cement, 1.5 parts by weight of bentonite for drilling fluid, 1 part by weight of sodium nitrate, and 0.2 parts by weight of triisopropanol 2.8 parts by weight of amine and aluminum powder are dry-blended to form a dry powder mixture. Measure 85 parts by weight of water, weigh 6 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 2.1 parts by weight of ethylenediamine tetramethylene phosphoric acid, and dissolve 1.5 parts by weight of sulfonated alkylnaphthalene formaldehyde resin in water , put the aqueous solution in the mixing container, the agitator rotates at a low speed (4000±200 rpm), and add the weighed dry powder mixture within 15 seconds, cover the lid of the agitator, and turn it at a high speed (12000±500 rpm) Min) and continue to stir for 35 seconds to obtain the cement slurry with large temperature diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com