Nontoxic calcium and zinc thermal stabilizer

A heat stabilizer, calcium-zinc technology, applied in the field of non-toxic calcium-zinc heat stabilizers, can solve the problems of extended stability time, poor processability of stabilizers, single stability performance, etc., achieve excellent static performance, improved processing performance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

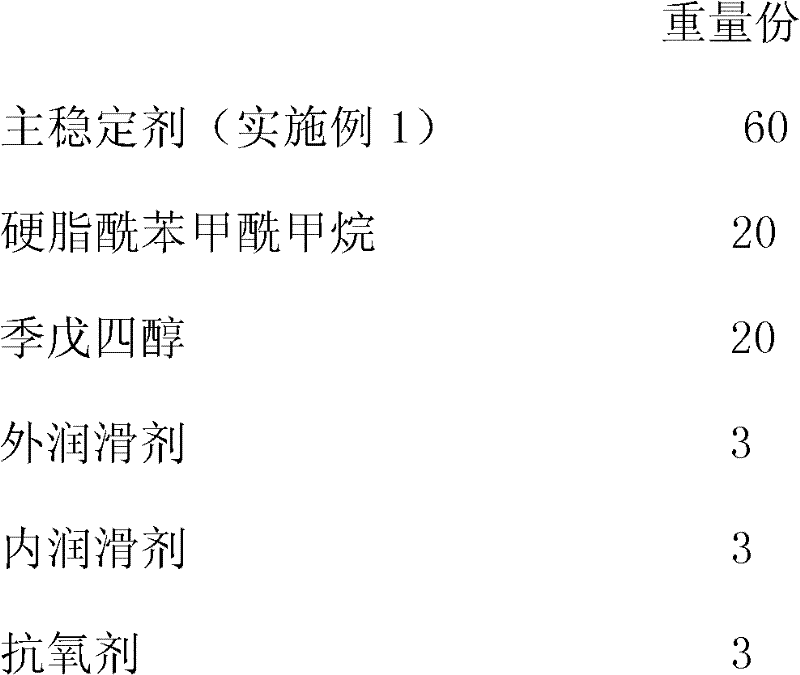

Embodiment 1

[0026] Preparation of main stabilizer;

[0027] a) Add 0.05 mol of stearic acid and 0.05 mol of benzoic acid into a 1000 ml three-necked flask, heat up to 70° C. until completely melted.

[0028] b) Dissolve 0.1 mol of sodium hydroxide (slightly excessive) in a 100ml beaker, add dropwise to a three-necked flask with a dropping funnel, drop it in ten minutes, and maintain the reaction for half an hour.

[0029] c) Raise the temperature to 85°C, then weigh 0.025 mol of zinc sulfate heptahydrate and 0.025 mol of calcium chloride into a 50ml beaker to dissolve completely, add zinc sulfate and calcium chloride at the same time with a dropping funnel, and drop them in half an hour , and maintain the reaction for 1 hour.

[0030] e) The product was washed with water, suction filtered, and dried in an oven at 80° C. for 12 hours until constant weight.

Embodiment 2

[0032] Preparation of primary stabilizer:

[0033] a) Add 0.05 mol of stearic acid and 0.05 mol of benzoic acid into a 1000 ml three-necked flask, heat up to 80-90° C. until completely melted.

[0034] b) Dissolve 0.1 mol of sodium hydroxide (slightly excessive) in a 100ml beaker, add dropwise to a three-necked flask with a dropping funnel, drop it in ten minutes, and maintain the reaction for half an hour.

[0035] c) The temperature is raised to 95° C., and then the zinc chloride of 0.025 mol is weighed and completely dissolved, and then added into the flask with a dropping funnel, and then 0.025 mol of calcium chloride is weighed and added to a 50 ml beaker to completely dissolve, and then added respectively with the dropping funnel, Dropping finished in half an hour, and finally maintained the reaction for 1 hour.

[0036] e) The product was washed with water, suction filtered, and dried in an oven at 80° C. for 12 hours until constant weight.

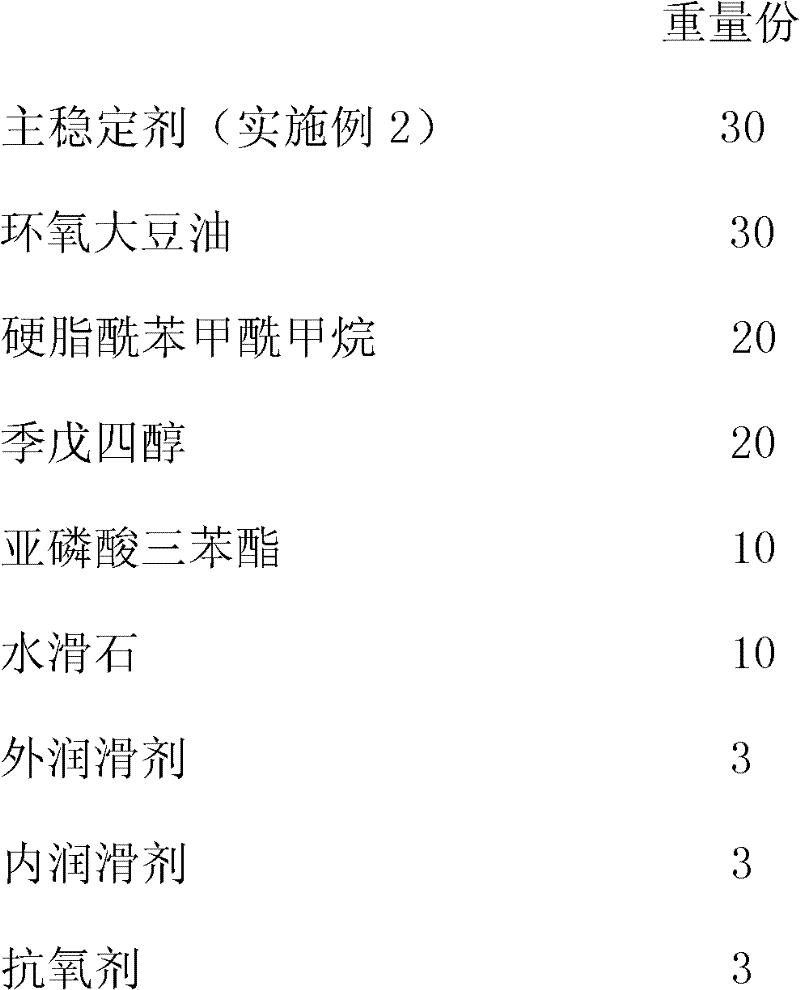

Embodiment 3

[0038] Preparation of primary stabilizer:

[0039] a) Add 0.05 mol of stearic acid and 0.1 mol of benzoic acid into a 1000 ml three-necked flask, heat up to 80-90° C. until completely melted.

[0040] b) Dissolve 0.15 mol of sodium hydroxide (slightly excessive) in a 100 ml beaker, add it into a three-necked flask with a dropping funnel, drop it in ten minutes, and maintain the reaction for half an hour.

[0041] c) Raise the temperature to 95°C, then weigh 0.03 mol of calcium chloride to dissolve completely and add it into the flask first with a dropping funnel, then weigh 0.03 mol of zinc sulfate heptahydrate and add it to a 50ml beaker to dissolve completely, then add it separately with a dropping funnel , respectively controlled for half an hour to finish dripping, and finally maintained the reaction for 1 hour.

[0042] e) The product was washed with water, suction filtered, and dried in an oven at 80° C. for 12 hours until constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com