Modified thermoplastic phenolic resin and preparation method for same

A phenolic resin and thermoplastic technology, applied in the field of modified thermoplastic phenolic resin and its preparation, can solve the problems of complicated process and long production cycle, and achieve the effect of simple process, short production cycle and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

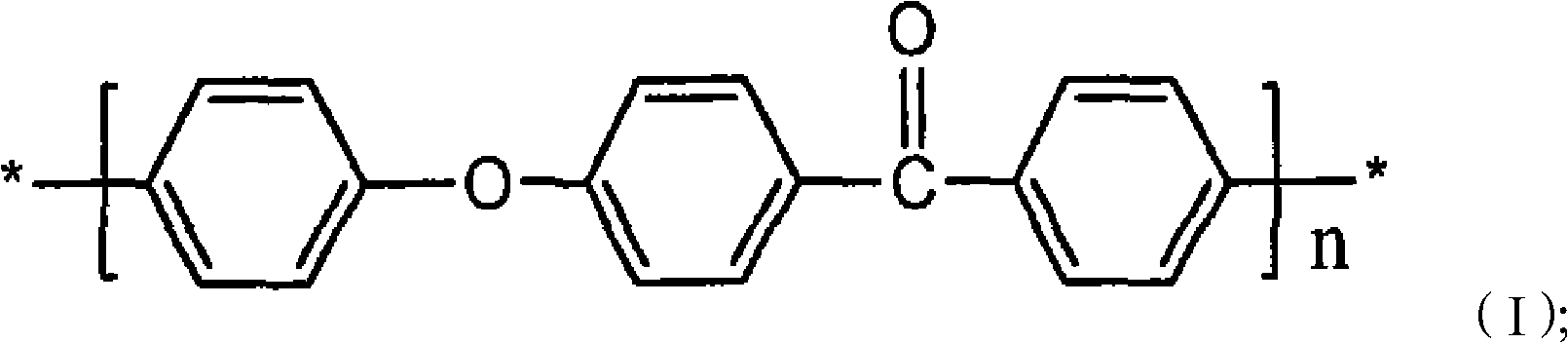

[0022] The invention provides a kind of preparation method of modified thermoplastic phenolic resin, comprises the following steps:

[0023] dissolving polyetheretherketone in phenolic compounds to obtain a first solution;

[0024] The polycondensation reaction between the first solution and the aldehyde compound occurs under the catalysis of the catalyst to obtain a modified thermoplastic phenolic resin, and the polyetheretherketone accounts for the total mass of the polyether ether ketone, the phenolic compound and the aldehyde compound. 0.5% to 20%.

[0025] The present invention directly dissolves polyether ether ketone in phenolic compounds, which not only overcomes the insoluble defect of polyether ether ketone, but also does not require pretreatment such as sulfonation and chloromethylation of polyether ether ketone, so that polyetherether ether Ketones, phenolic compounds and aldehyde compounds undergo polycondensation reaction under the catalysis of the catalyst to o...

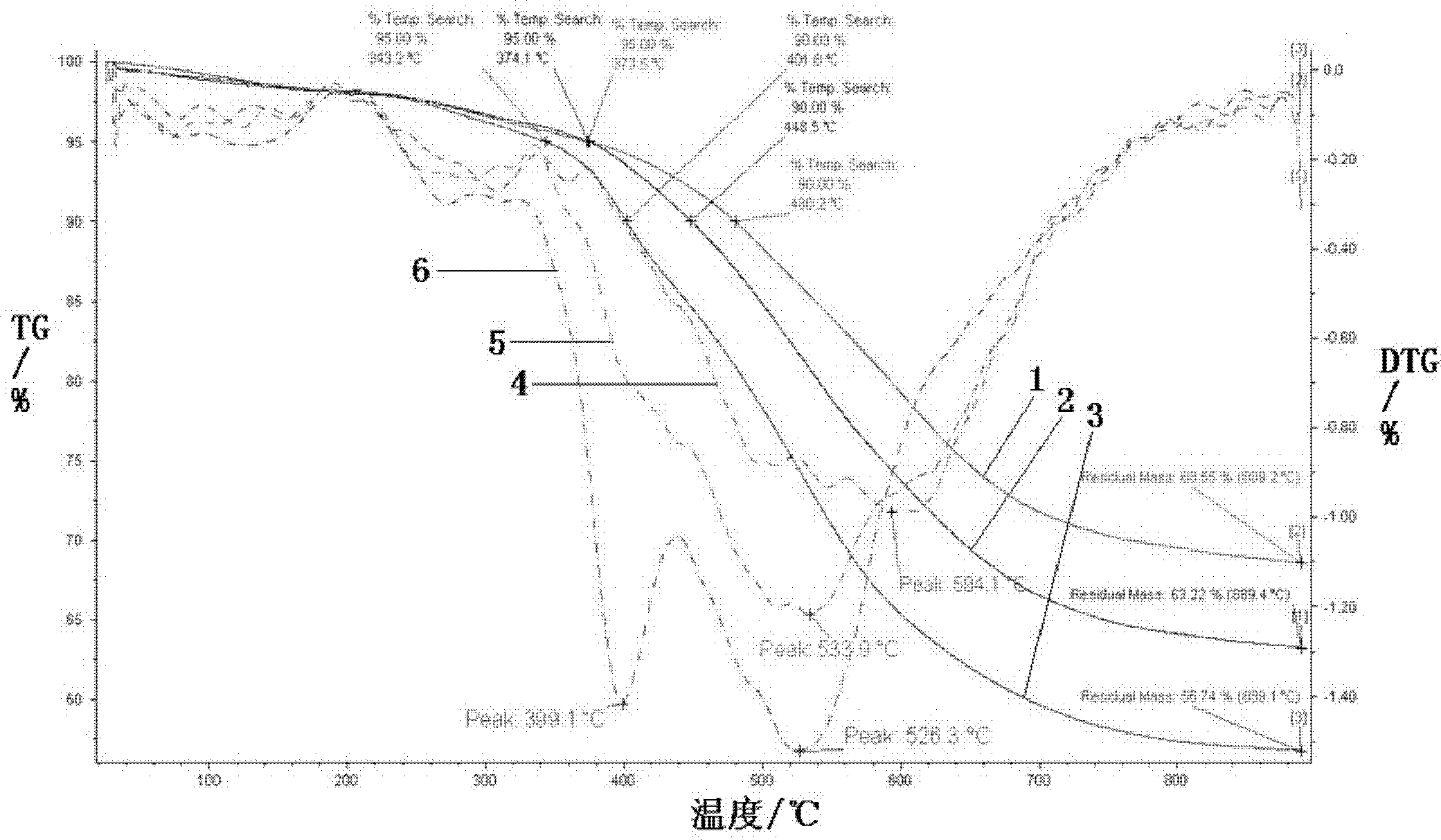

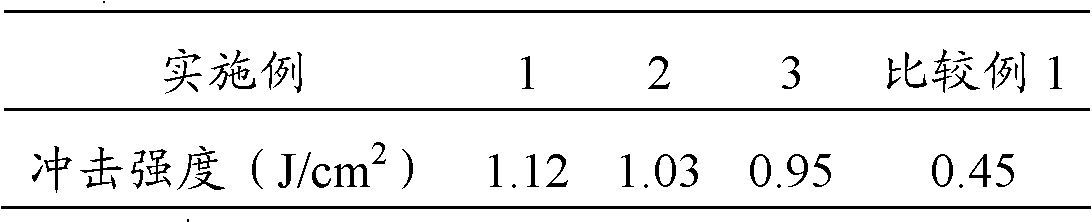

Embodiment 1

[0044] Pure resin polyether ether ketone injection molding pellets purchased from Nanjing Shousu Special Engineering Plastic Products Co., Ltd. were pulverized into 250-mesh powder.

[0045] Add 500g of phenol into a reaction vessel with a thermometer, a stirring device, and a reflux condenser, heat up to 170°C, add 30g of the polyetheretherketone powder, and stir to dissolve; when the polyetheretherketone is completely dissolved, cool down the reaction material To 60°C, add 5g of oxalic acid, 345g of formaldehyde solution with a mass concentration of 37%, raise the temperature to 100°C, react at a constant temperature for 3 hours, finish the reaction and carry out atmospheric distillation, heat to 170°C, and then distill under reduced pressure at 8000Pa to obtain 525g modified thermoplastic phenolic resin.

Embodiment 2

[0047] Pure resin polyether ether ketone injection molding pellets purchased from Nanjing Shousu Special Engineering Plastic Products Co., Ltd. were pulverized into 200-mesh powder.

[0048] Add 500g of phenol and 50g of cresol into a reaction vessel equipped with a thermometer, a stirring device, and a reflux condenser, heat up to 170°C, add 25g of the polyetheretherketone powder, and stir to dissolve; when the polyetheretherketone is completely dissolved Cool the reaction mass to 60°C, add 5g of oxalic acid and 361g of formaldehyde solution with a mass concentration of 37%, raise the temperature to 100°C, react at a constant temperature for 3 hours, finish the reaction and carry out atmospheric distillation, heat to 170°C, and then decompress under 8000Pa pressure Pressure distillation yielded 603g of modified thermoplastic phenolic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com