Self-compacting concrete mixture for plate-type ballastless track of railway

A slab-type ballastless track and self-compacting concrete technology, which is applied in the field of self-compacting concrete, can solve problems such as joint separation, easy segregation, and easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The content of the present invention is further described below in conjunction with the examples, but the content of the present invention is not limited only to the following examples.

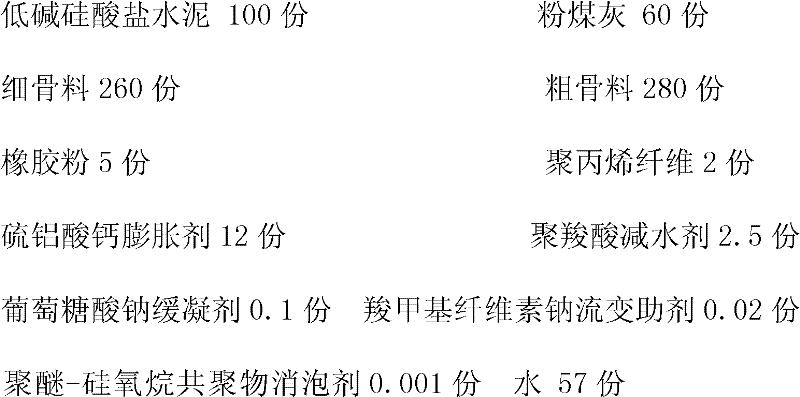

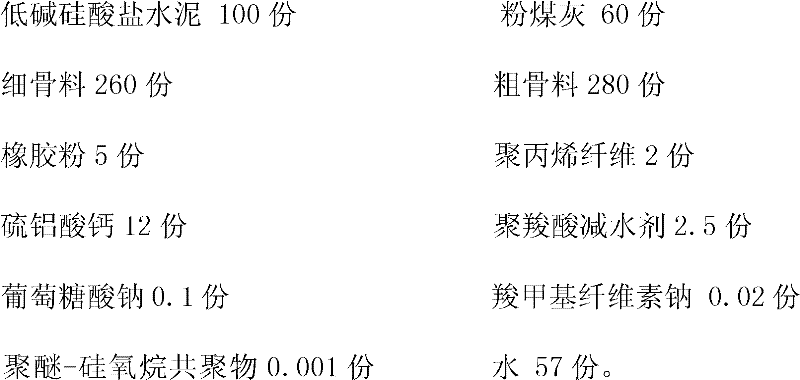

[0023] The super-early-strength grouting material for railway ballastless track structure repair of this embodiment is composed of ultra-fine cement, admixture, redispersible latex powder, polymer emulsion, expansion agent, water reducer, coagulant, retarder agent, rheology additive, and defoamer are mixed and stirred on site. The parts by weight of each component are:

[0024]

[0025] The performance indicators of the obtained fresh concrete mixture are: the time required for the slump cylinder to expand to 500mm is 4s, the expansion degree is 650mm, the height difference of the "J" ring is 14mm, the time for the "L" meter is 9s, and the time for the "L" meter is two seconds. The side height ratio is 0.91; the hardened concrete performance indicators are: 3d compressive strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com