Production method for preparing composite particle glass raw material by utilizing silica powder waste and application thereof

A technology for composite granules and glass raw materials, applied in the field of preparing composite granulated glass raw materials, can solve the problems of large consumption of heavy soda ash, high production cost, environmental pollution, etc., to optimize the quality of glass raw materials, reduce raw material costs, and reduce melting temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

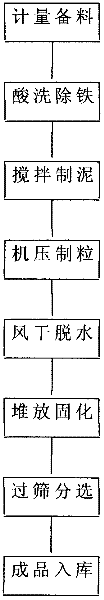

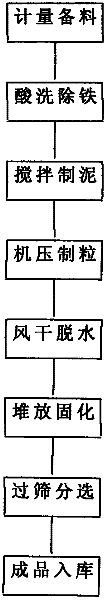

Method used

Image

Examples

Embodiment 1

[0088] A kind of production method that utilizes silica sand powder to prepare above-mentioned composite particle glass raw material, it is to carry out according to the following steps successively:

[0089] (1) Measuring and preparing materials: weigh materials according to the following proportions by weight:

[0090] Silica sand powder 1.0 parts,

[0091] 1.0 parts of light soda ash,

[0092] 0.6 parts of water.

[0093] The above-mentioned silica sand powder refers to the fine powder of silica sand below 150 mesh.

[0094] The weight portion proportioning of above-mentioned light soda ash is by Na 2 CO 3 count.

[0095] (2) Pickling and iron removal: Prepare 20% dilute sulfuric acid solution in the pickling tank, wash the silica sand powder in the pickling tank, and make the iron ion Fe contained in the silica sand powder material +2 , Fe +3 It can fully contact with the dilute sulfuric acid solution to the greatest extent to react, and remove the Fe contained in t...

Embodiment 2

[0109] A kind of production method that utilizes silica sand powder to prepare above-mentioned composite particle glass raw material, it carries out according to the following steps successively:

[0110] (1) Measuring and preparing materials: weigh materials according to the following proportions by weight:

[0111] Silica sand powder 1.0 parts,

[0112] 0.5 parts of light soda ash,

[0113] 0.4 parts of water.

[0114] The above-mentioned silica sand powder refers to the fine powder of silica sand below 150 mesh.

[0115] The weight portion proportioning of above-mentioned light soda ash is by Na 2 CO 3 count.

[0116] Then operate according to the method described in the first (2) to (8) steps in Example 1, the composite particle glass raw material can be obtained: it is a solid granular composition, and its main components are: SiO 2 、Na 2 SiO 3 、Na 2 CO 3 , NaHCO 3 , and the rest are Al 2 o 3 , CaO, MgO, K 2 O and unavoidable mineral impurities, its particle...

Embodiment 3

[0118] A kind of production method that utilizes silica sand powder to prepare above-mentioned composite particle glass raw material, it carries out according to following steps successively:

[0119] (1) Measuring and preparing materials: weigh materials according to the following proportions by weight:

[0120] Silica sand powder 1.0 parts,

[0121] 1.5 parts of light soda ash,

[0122] 0.8 parts of water.

[0123] The above-mentioned silica sand powder refers to the fine powder of silica sand below 150 mesh.

[0124] The weight portion proportioning of above-mentioned light soda ash is by Na 2 CO 3 count.

[0125] (2) Pickling and iron removal: Use a circulation pump to extract 20% of the dilute salt solution to spray and circularly wash the silica sand powder, so that the dilute salt solution and the iron ion Fe contained in the silica sand powder material +2 , Fe +3 Fully contact and react, the Fe contained in the silica sand powder can be separated and removed +2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com