Additive and chemical tempering process for glass

A chemical tempering and additive technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as hindering ion exchange, accelerating ion exchange, etc., achieving stable ion exchange quality, increasing K+ concentration, and purifying molten salt. The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A chemical tempering process for glass, the method comprising the following steps:

[0015] (1) Process the sodium aluminum silicate system glass into a thin slice of 110mm×55mm×0.55mm;

[0016] (2) cleaning and drying the processed glass;

[0017] (3) the additive of the present invention is added KNO according to the weight ratio of 1: 24 3 In molten salt, heated to 410°C and kept at a constant temperature for 50 hours, the weight percent of additives is composed of: potassium hydroxide: 2%, potassium carbonate: 4%, diatomaceous earth 94%;

[0018] (4) Rapidly heat up the dried glass in step (2) to 350° C., and keep it warm for 50 minutes;

[0019] (5) Put the glass into the prepared molten salt and process it for 10 hours to carry out ion exchange;

[0020] (6) cooling and cleaning the ion-exchanged glass to obtain chemically tempered glass.

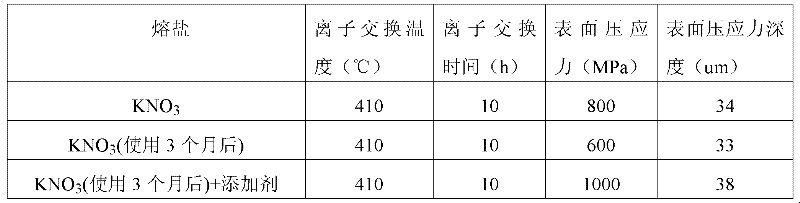

[0021] After the above ion exchange, a compressive stress layer of about 38um is formed on the glass surface, the surface...

Embodiment 2

[0023] (1) Process the sodium aluminum silicate system glass into a thin slice of 110mm×55mm×0.55mm;

[0024] (2) cleaning and drying the processed glass;

[0025] (3) The additive of the present invention is added KNO according to the weight ratio of 1: 20 3 In molten salt, heated to 440°C and kept at constant temperature for 24 hours, the weight percentage of additives is: potassium hydroxide: 4%, potassium carbonate: 6%, diatomaceous earth 90%;

[0026] (4) Rapidly heat up the dried glass in step (2) to 380° C., and keep it warm for 30 minutes;

[0027] (5) Put the glass into the prepared molten salt and process it for 4 hours to carry out ion exchange;

[0028] (6) cooling and cleaning the ion-exchanged glass to obtain chemically tempered glass.

[0029] After the above ion exchange, a compressive stress layer of about 38um is formed on the glass surface, the surface stress can reach about 950MPa, and the service life of the salt bath is ≥10 months.

Embodiment 3

[0031] (1) Process the soda-lime-silicon system glass into thin slices of 110mm×55mm×0.55mm;

[0032] (2) cleaning and drying the processed glass;

[0033] (3) the additive of the present invention is added KNO according to the weight ratio of 1: 17 3 In molten salt, heated to 400°C and kept at a constant temperature for 70 hours, the weight percentage of additives is: potassium hydroxide: 8%, potassium carbonate: 10%, diatomaceous earth 82%;

[0034] (4) Rapidly heat up the dried glass in step (2) to 300° C., and keep it warm for 90 minutes;

[0035] (5) Put the glass into the prepared molten salt and process it for 24 hours to carry out ion exchange;

[0036] (6) cooling and cleaning the ion-exchanged glass to obtain chemically tempered glass.

[0037] After the above ion exchange, a compressive stress layer of about 55um is formed on the glass surface, the surface stress can reach about 900MPa, and the service life of the salt bath is ≥10 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface stress | aaaaa | aaaaa |

| Surface stress | aaaaa | aaaaa |

| Surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com