System for treating heavy metal wastewater

A waste water treatment system, heavy metal technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of serious scaling, exceeding the standard, and low removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

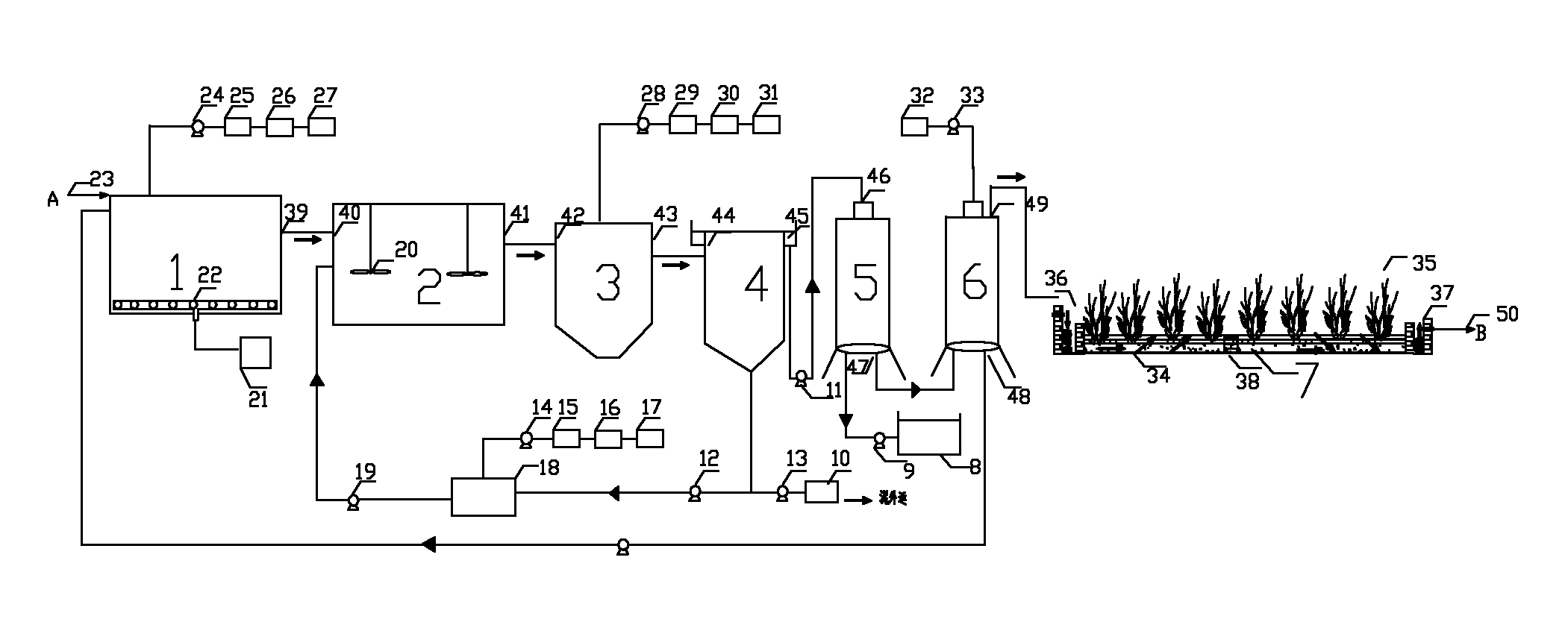

[0022] The preferred embodiment of the heavy metal wastewater treatment system of the present invention is:

[0023] It is mainly composed of aeration tank, neutralization tank, flocculation tank, thickening tank, mechanical filter tank, adsorption column and functional wetland in sequence. Wastewater flows into the system from the inlet of the aeration tank and is discharged from the outlet of the functional wetland.

[0024] The bottom of the aeration tank is provided with a microporous aeration device, and the Fe in the wastewater is removed by aeration. 2+ oxidized to Fe 3+ , increase Fe in the aeration tank 3+ concentration. At the same time, the system is equipped with an iron salt dosing system, which is fed by Fe 2 (SO 4 ) 3 Storage tank, Fe 2 (SO 4 ) 3 Dissolution tank, Fe 2 (SO 4 ) 3 Reservoir and Fe 2 (SO 4 ) 3 Solution metering pump composition, Fe 2 (SO 4 ) 3 The storage tank is equipped with Fe with a concentration of 0.1mol / L~1mol / L 2 (SO 4 )...

specific Embodiment

[0032] like figure 1 As shown, the heavy metal wastewater treatment system is mainly composed of an aeration tank 1, a neutralization tank 2, a flocculation tank 3, a thickening tank 4, a mechanical filter tank 5, an adsorption column 6, and a functional wetland 7.

[0033] The raw water A of the heavy metal wastewater in the non-ferrous metal mining area enters the aeration tank 1 from the water inlet 23 of the aeration tank 1. The bottom of the aeration tank 1 is equipped with a microporous aeration device 22, and the air is blown in by the blower 21, and the aeration Fe in wastewater 2+ Oxidized to Fe 3+ . At the same time, the heavy metal wastewater system is equipped with an iron salt dosing system, which consists of Fe 2 (SO 4 ) 3 Storage tank 27, Fe 2 (SO 4 ) 3 Dissolving tank 26, Fe 2 (SO 4 ) 3 Reservoir 25 and Fe 2 (SO 4 ) 3 Solution metering pump 24 forms. Fe 2 (SO 4 ) 3 Fe in storage tank 27 2 (SO 4 ) 3 The solid is shaken off to Fe 2 (SO 4 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com