Method for realizing biogas slurry reutilization by recycling biogas slurry

A technology of resource utilization and biogas slurry, which is applied in the direction of chemical instruments and methods, methods based on microorganisms, biochemical equipment and methods, etc., to achieve the effects of wide application range, reduced operating costs and floor space, and multiple means of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

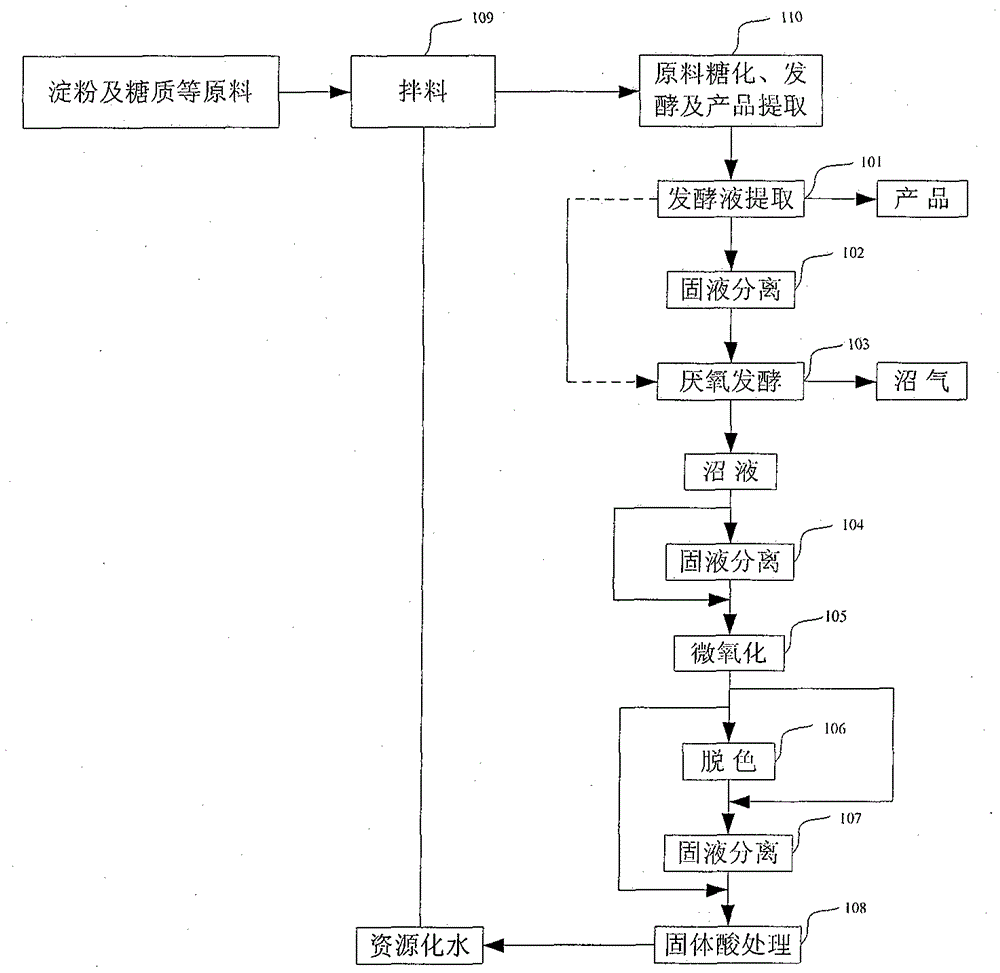

[0047] Embodiment one: a kind of method that realizes biogas slurry reuse to produce alcohol, such as figure 2 As shown, it mainly includes the following process steps:

[0048] Step 201: The alcoholic fermentation liquid is distilled to obtain distillation waste liquid and products, and the total COD of the distillation waste liquid is 100000 mg / L;

[0049] Step 202: The alcohol distillation waste liquid undergoes solid-liquid separation to obtain centrifuged mother liquor and distiller's grains; here, step 202 can be selected according to actual needs;

[0050] In this embodiment, this step is selected to be performed, and the solid-liquid separation adopts the decanter centrifugation method for separation, and the solid-liquid separation adopts other separation methods and does not affect the implementation of this example;

[0051] Step 203: Cool the waste liquid from step 201 or step 202 to 55°C, enter the first-stage high-temperature anaerobic UASB reactor, maintain th...

Embodiment 2

[0062] Embodiment two: a kind of method that realizes biogas slurry reuse to produce alcohol:

[0063] Different from the first embodiment above, in this embodiment, if figure 2 Shown include the following process steps

[0064] Step 201: The alcohol fermentation liquid is distilled to obtain distillation waste liquid and products, and the total COD of the distillation waste liquid is 95000 mg / L;

[0065] In this embodiment, step 202 is not selected;

[0066] In step 203: will enter the first-stage high-temperature anaerobic UASB reactor, adjust the maintenance temperature to 50°C, and adjust the hydraulic retention time (HRT) to 6d;

[0067] In this embodiment, step 204 is selected to be executed, and the solid-liquid separation adopts horizontal screw centrifugation and then is separated in series by a plate-and-frame filtration method;

[0068] In step 205: maintain the temperature and adjust it to 50° C., feed air with an air ratio of 6 L / L.min and keep stirring for 2 ...

Embodiment 3

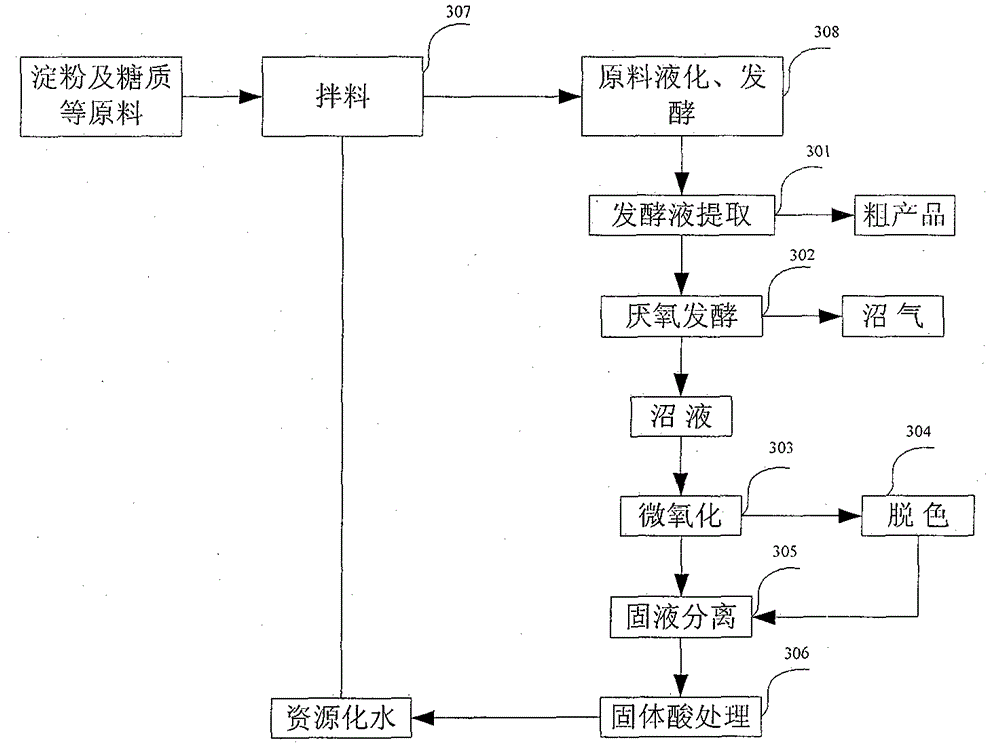

[0074] Embodiment three: a kind of method that realizes biogas slurry reuse to produce citric acid, such as image 3 As shown, it mainly includes the following process steps:

[0075] Step 301: The citric acid fermentation broth adopts the method of calcium salt precipitation to obtain the extraction waste liquid and the crude product, and the total COD of the extraction waste liquid is 15000 mg / L; using other extraction methods does not affect the implementation of the present invention;

[0076] Step 302: Put the extraction waste liquid into the first-stage high-temperature anaerobic UASB reactor, maintain the temperature at 60° C., maintain the hydraulic retention time (HRT) at 2 days, and keep the pH at 7.5-8.0. The first-stage high-temperature anaerobic effluent undergoes natural settlement and is cooled to 45°C at the same time. The settled sludge is filtered through a plate and frame, and the filtrate and effluent enter the second-stage medium-temperature UASB reactor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com