Activated sludge culture method suitable for high-salt sewage

A technology for high-salt sewage and activated sludge, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Plant operation and other issues, to achieve the effect of simple cultivation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: This activated sludge culture method suitable for high-salt sewage adopts the following process steps.

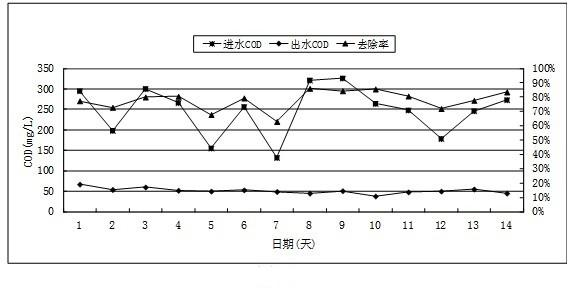

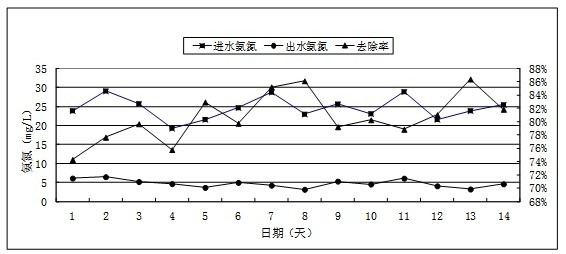

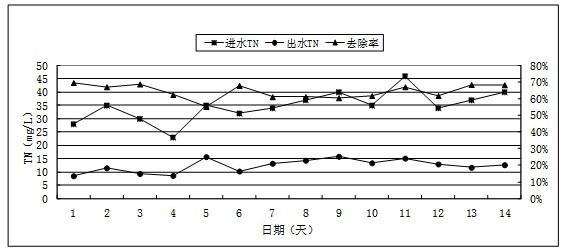

[0023] 1. Equipment and raw materials: the total effective pool capacity of the biochemical pool used is about 5400m 3 ;Water quality of high salinity sewage to be treated: PH: 6~9, COD 120mg / L, TP 1.8mg / L, TN 45mg / L, ammonia nitrogen 28mg / L, BOD 20mg / L, chloride 6000mg / L; The nutrients are configured from industrial grade glucose, phosphate fertilizer and urea, and its composition ratio is BOD 5 :N:P=100:5:1.

[0024] 2. The steps of cultivating and domesticating are:

[0025] (1) Poor exposure: put 200m in the biochemical pool 3 The seed mud (accounting for 3.7% of the tank capacity), then add sewage with a chloride ion concentration of 1000mg / L and a COD of 350mg / L until the biochemical tank is full, and carry out stuffy exposure; after 10 days, the degradation rate of COD reaches 45-55%, then stop Stuffy exposure: during the stuffy exposure peri...

Embodiment 2

[0028] Embodiment 2: This activated sludge cultivation method suitable for high-salt sewage adopts the following process steps.

[0029] 1, equipment and raw material are identical with embodiment 1.

[0030] 2. The steps of cultivating and domesticating are:

[0031] (1) Stuffed exposure: except that the amount of seed mud input accounts for 3.0% of the pool volume, the chlorine ion concentration of the added sewage is 500 mg / L, and the COD is 250 mg / L, the rest of the steps are the same as in Example 1;

[0032] (2) Intermittent water intake: In addition to the 2.0h static settling at the end of the boring exposure, the discharge of the supernatant accounts for 9.0% of the pool volume, and the injection of high-salt sewage accounts for 9.0% of the pool volume until the chloride ion concentration in the biochemical pool is equal to the chloride ion concentration of the high-salt sewage. Except 90.0%, all the other steps are identical with embodiment 1;

[0033] (3) Continuo...

Embodiment 3

[0034] Embodiment 3: This activated sludge culture method suitable for high-salt sewage adopts the following process steps.

[0035] 1, equipment and raw material are identical with embodiment 1.

[0036] 2. The steps of cultivating and domesticating are:

[0037] (1) Stuffed exposure: Except that the amount of seed mud input accounts for 5.0% of the pool volume, the chlorine ion concentration of the added sewage is 750mg / L, and the COD is 300mg / L, the rest of the steps are the same as in Example 1;

[0038](2) Intermittent water intake: In addition to the static settling for 1.0h at the end of the boring exposure, the discharge of the supernatant accounts for 18% of the pool volume, and the injection of high-salt sewage accounts for 18% of the pool volume until the concentration of chloride ions in the biochemical pool is equal to the concentration of chloride ions in high-salt sewage. Except 99%, all the other steps are identical with embodiment 1;

[0039] (3) Continuous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com