Method for preparing cuprous oxide (Cu2O) with hierarchical flower-like structure

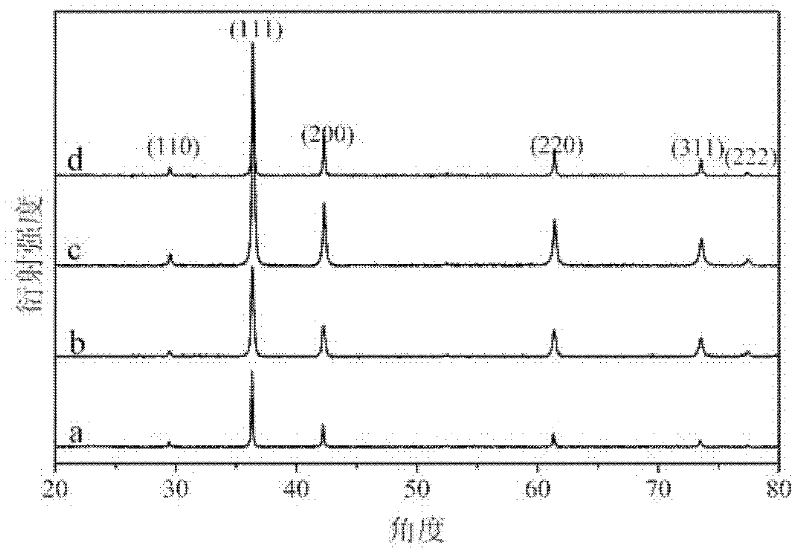

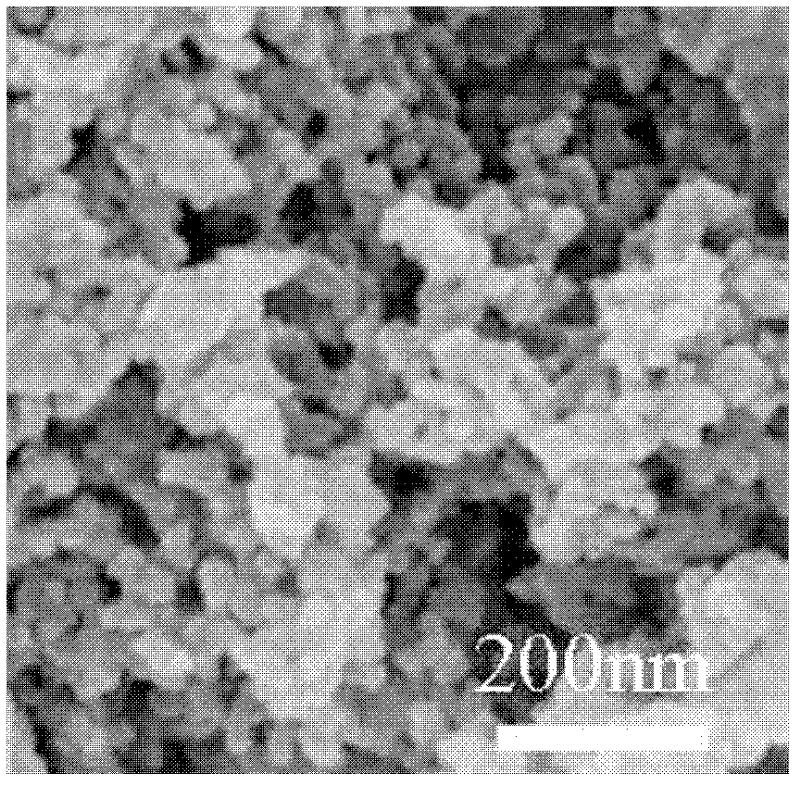

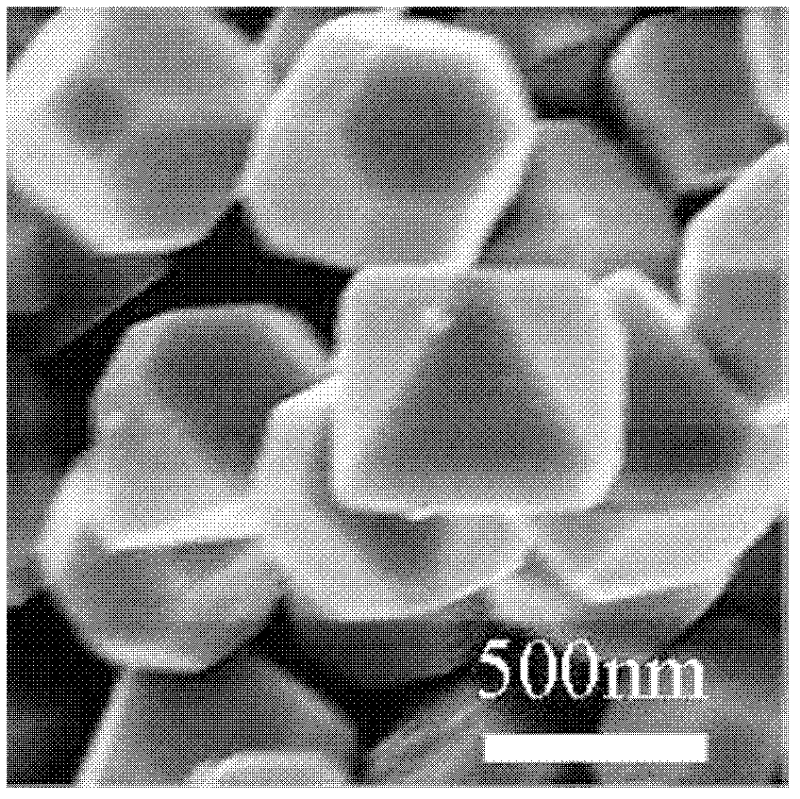

A cuprous oxide, flower-like structure technology, applied in the field of preparation of nano-cuprous oxide, can solve the problems of small specific surface area and low roughness factor, and achieve increased specific surface area, obvious pore size distribution, high crystallinity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Embodiment 1: This embodiment is a method for preparing cuprous oxide with a hierarchical flower-like structure, which is specifically completed according to the following steps:

[0011] 1. Preparation of copper salt solution: completely dissolve copper salt in water at room temperature, and configure it into Cu 2+ A solution of copper salt with a molar concentration of 0.014 to 0.02mol / L; 2. Activation: add a nonionic surfactant to the solution of copper salt prepared in step 1 at room temperature, and stir at 100r / min to 300r / min Stir at high speed for 10min to 90min to obtain the activated copper salt solution; 3. Reduction: Use a micro-injector to drip the reducing agent solution into the activated copper salt solution at a rate of five drops per minute, and set the solution at 20°C At ~50°C, stir at a stirring speed of 200r / min~400r / min for 150min~300min to obtain a cuprous oxide precipitate; 4. Separation and washing: separate the cuprous oxide precipitate prepar...

specific Embodiment approach 2

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the copper salt described in step 1 is copper acetate, copper nitrate, anhydrous copper sulfate, anhydrous copper sulfate or copper chloride. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the nonionic surfactant described in step two is selected from polyvinylpyrrolidone, propylene glycol polyoxypropylene polyoxyethylene ether, isomeric Alcohol polyoxyethylene polyoxypropylene ether, polyurethane polyoxypropylene polyoxypropylene ether, polyethylene glycol monooleate, stearyl ethylene urea, coconut oil reduced alcohol, cetyl alcohol, oleyl alcohol, oleic acid and hard Fatty acid. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com