Device for conveying scaffold cars

A technology of conveying device and gantry car, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as restricting automatic control of welding production line, increasing operator's labor intensity, affecting welding production efficiency, etc., and achieves improved automation. The effect of controlling level, reducing labor intensity and improving welding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

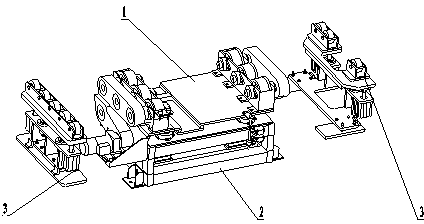

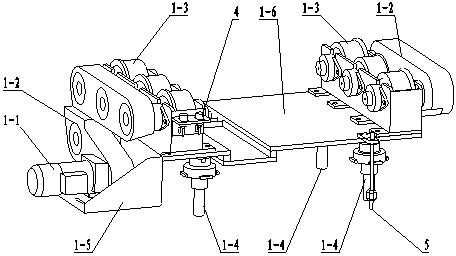

[0017] Referring to Figures 1 and 2, the composition of the present invention includes a horizontal conveying mechanism 1, a lifting mechanism 2, an auxiliary conveying mechanism 3, and a PLC control system. The horizontal conveying mechanism 1 includes a driving motor 1-1, a motor mounting bracket 1-5, The chain drive system 1-2, the rolling wheels 1-3, the guide column 1-4 and the mounting platform 1-6, the drive motor 1-1 is fixed on the motor mounting bracket 1-5, and its output shaft is connected to the chain drive system 1 -2 connection, the chain drive system 1-2 includes two symmetrical parts, respectively connected with the corresponding rolling wheels 1-3, the rolling wheels 1-3 are divided into two groups symmetrical, fixed on the installation platform Above 1-6, the guide posts 1-4 are fixed at the four corners of the bottom surface of the installation platform 1-6, and the motor mounting bracket 1-5 is fixed on the left side of the installation platform 1-6.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com