Automatic packaging machine

An automatic packaging machine, packaging machine technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve the problem of inability to automatically measure the specified value of viscous materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0268] This embodiment describes, illustrates and explains the lifting mechanism.

[0269] see Figure 31 .

[0270] Described elevating mechanism comprises: elevating base 8, elevating driving sub-mechanism, elevating support 11; Driven by the mechanism, the elevating support 11 moves up and down.

[0271] The lifting support 11 includes a vertical structure body 11a and a horizontal frame body 11b, the bottom of the horizontal frame body 11b is fixedly connected to the top of the vertical structure body 11a.

[0272] The lifting drive sub-mechanism includes: a hand pan 7, a nut 42, a transmission component, and a locking component 10; the transmission component, which is arranged inside the lifting base 8, includes: a turbine 41, a worm 40, a screw 43;

[0273] Described hand plate 7, it is positioned at the outside of lifting base 8, and its back is fixedly connected with the front part of worm; Lifting base 8 is rotatably connected and fixedly connected with the botto...

Embodiment 2

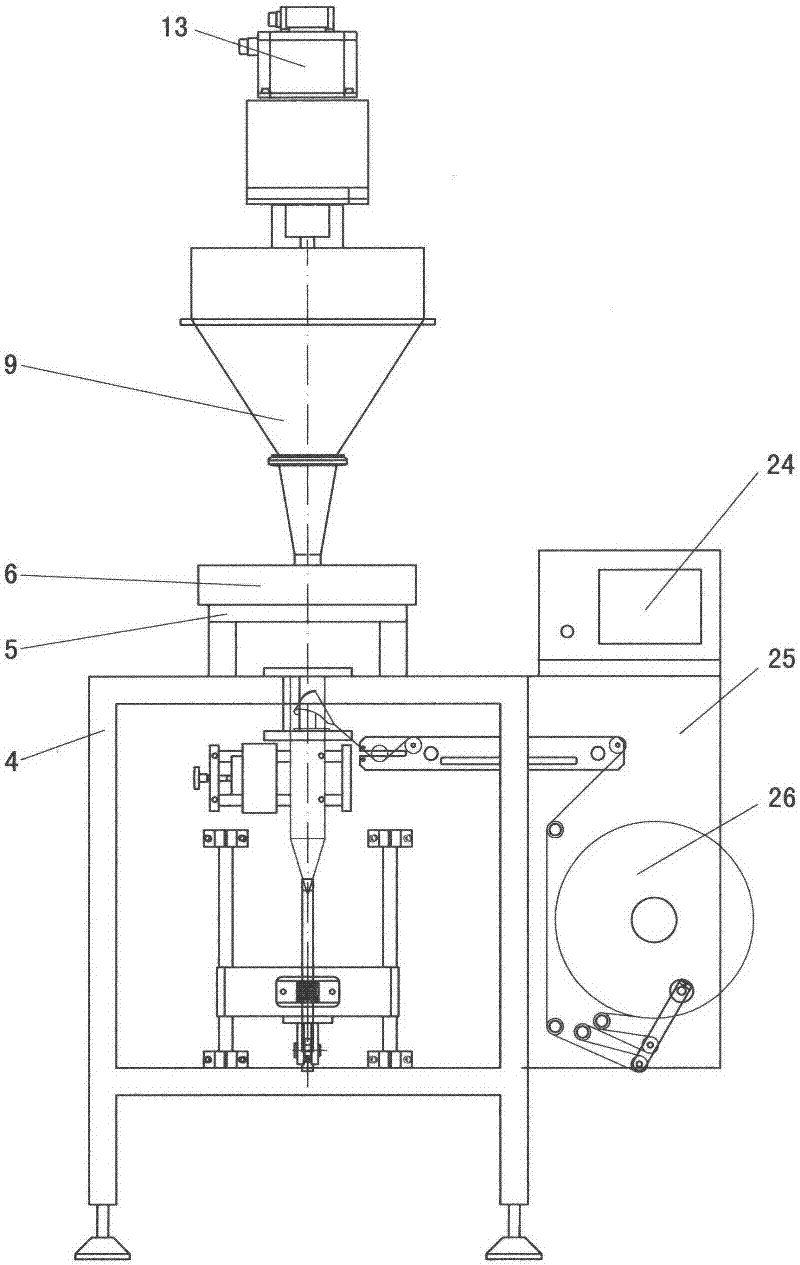

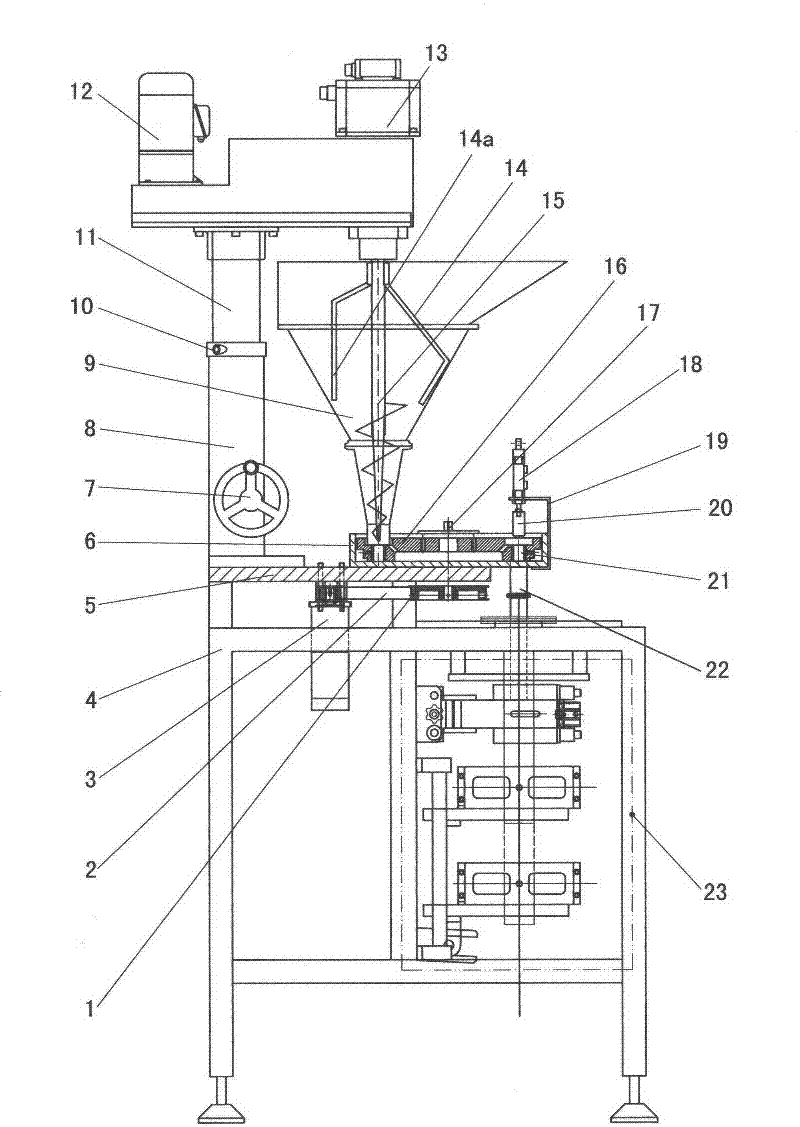

[0282] For the automatic packaging machine in this embodiment, see figure 1 and figure 2 . figure 1 It is the front view of the invented packaging machine. This figure is a schematic diagram, and some parts are omitted in the figure; figure 2 yes figure 1 The left view of , this figure is a schematic diagram, in which some components (such as control cabinets, etc.) are omitted.

[0283] The automatic packaging machine in this embodiment includes four categories: 1. frame 4; 2. automatic control circuit; 3. packaging equipment 23; 4. conveying equipment. The following four categories of machinery are introduced.

[0284] The first category: Rack 4.

[0285] Similar to ordinary machine equipment, this automatic packaging machine also needs a set of rack 4 systems to install various devices, equipment, mechanisms and components, and so on.

[0286] The second category: automatic control circuit.

[0287] Such as figure 1 As shown, the automatic packaging machine includ...

Embodiment 3

[0352] In the second embodiment above, an automatic packaging machine of the present invention is introduced from the perspective of hardware.

[0353] In the third embodiment, the automatic packaging machine in the second embodiment is taken as an object, and the height adjustment of the lifting support 11 is described and explained.

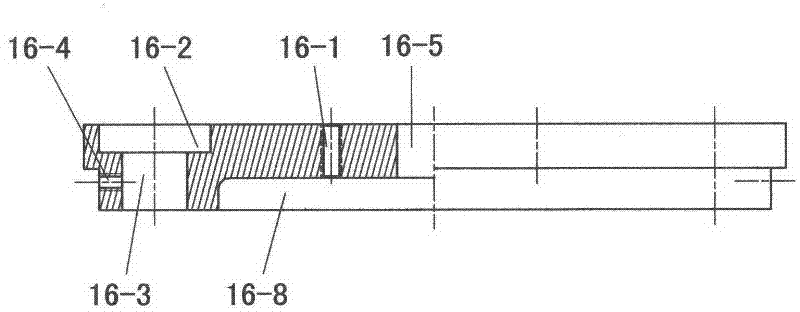

[0354] In daily production, if the variety or specification of the product is changed, the measuring cup 21 may need to be replaced, so that the lifting bracket 11 needs to be raised, and thus the hopper 9, the stirring rod 14 and the feeding rod 15 are jointly raised, etc., Then disassemble the rotating disk 16, replace the measuring cup 21, restore the installation of the rotating disk 16, finally make the lifting bracket 11 drop to a suitable height, and fix it by the locking part 10.

[0355] Below, combine Figure 15 The situation shown will be described. exist Figure 15 Among them, the hopper 9 is in the shape of a large top and a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com