Flexible bulletproof compound material with novel resin matrix and processing method thereof

A bulletproof composite material and resin matrix technology, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of large decline in ballistic performance, poor yellowing resistance, poor aging resistance, etc. Achieve the effects of small drop in bulletproof performance, good bulletproof performance, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

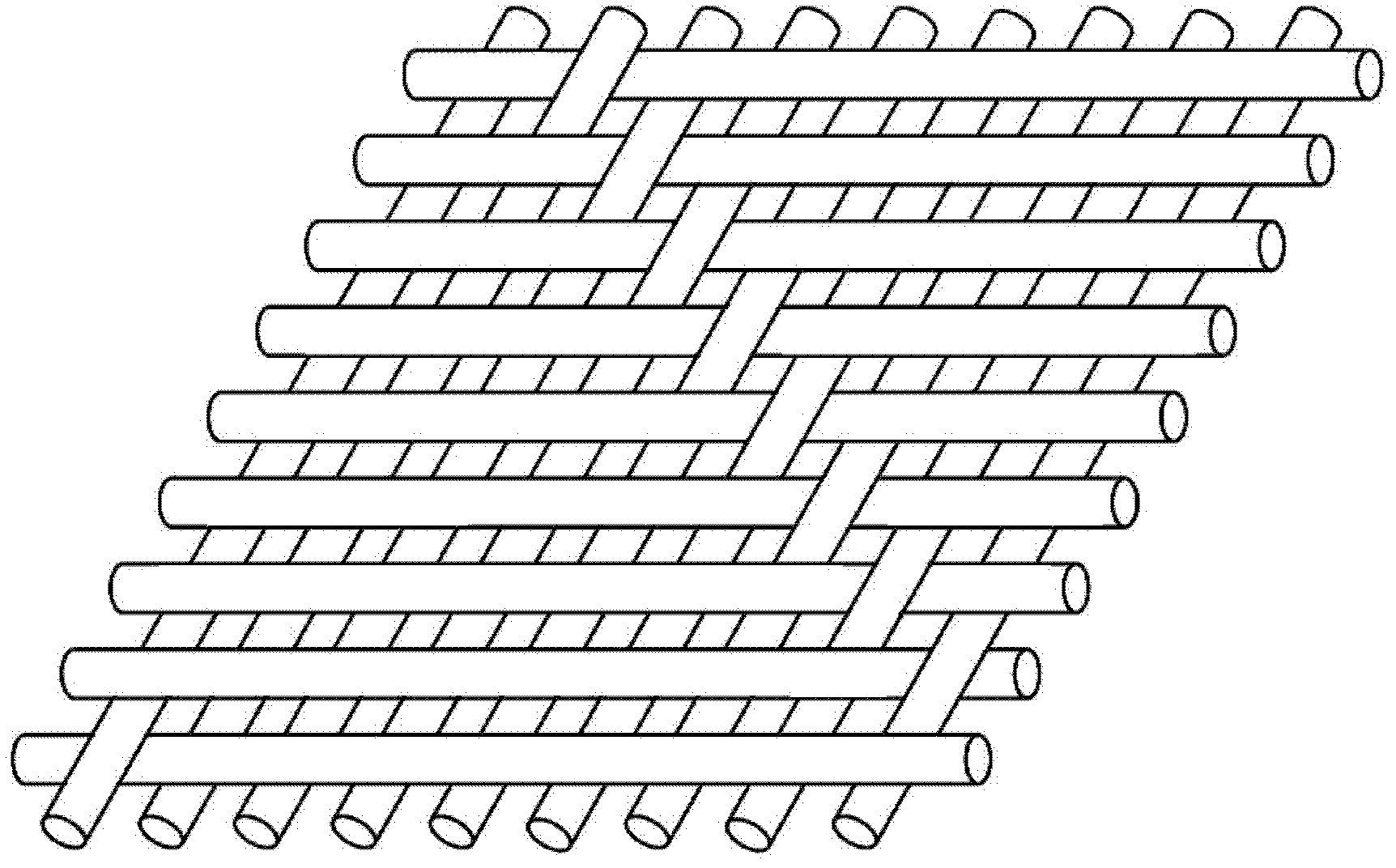

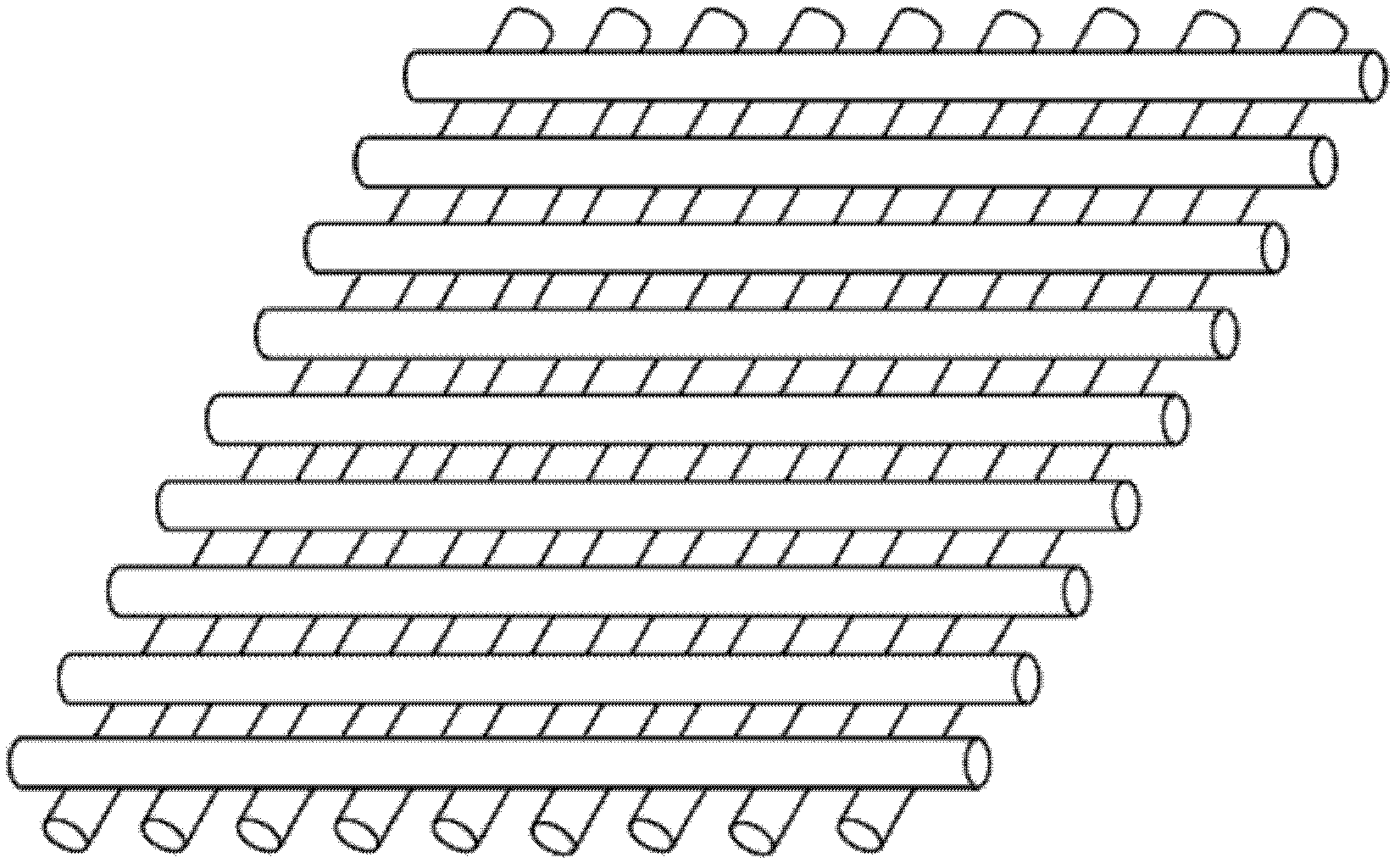

[0036] The flexible bulletproof composite material of the present invention is composed of high-strength filament fiber material (the main carrier of the projectile shock wave) and a matrix composed of resin 1 and resin 2 (the dispersion of the projectile shock wave). The high-strength filament fiber material is the main carrier of the projectile shock wave, which can consume most of the projectile shock function through its own fracture. The role of the matrix is to disperse the shock wave of the projectile, so that the shock wave propagates in the largest area, so as to mobilize more fibers to bear the shock wave, and reduce the fiber breakage caused by the repea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com