Column and sliding seat bonding face adhesive filing structure and process

A technology of combining surfaces and columns, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of time-consuming, occupying machine tool processing equipment, affecting the construction period, etc., to save installation time, reduce labor intensity, improve Ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

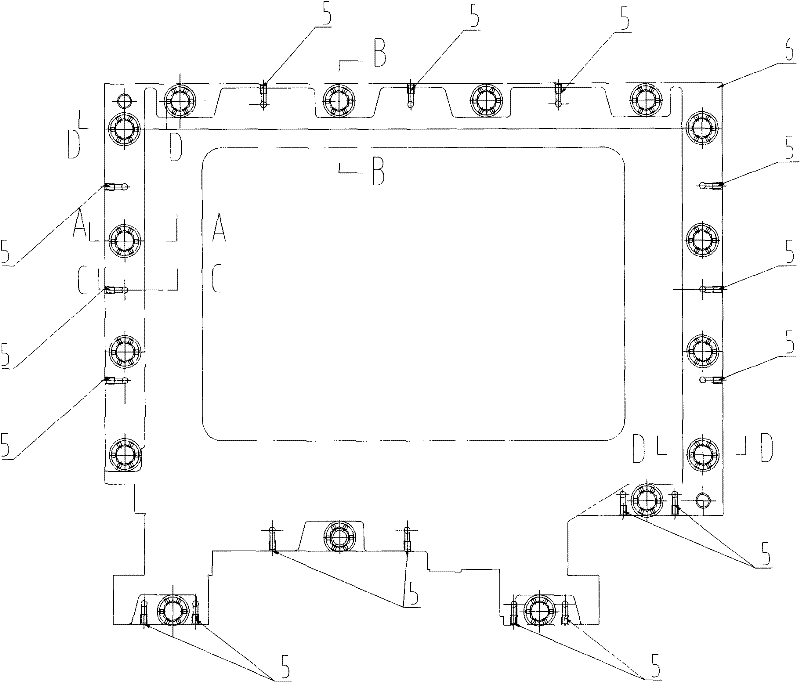

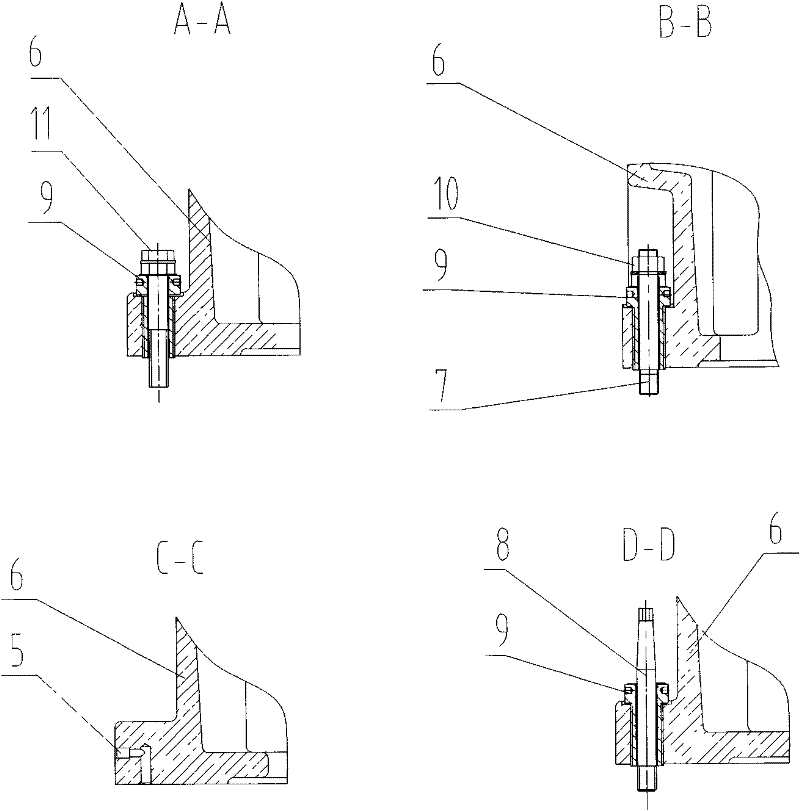

[0021] The glue-pouring structure of the joint surface of the column and the sliding seat of the present invention includes: a column, a sliding seat, a screw sleeve, a fastener, a rubber strip, a sealing ring and other components. A rubber strip 2 and a sealing ring 3 are provided on the sliding seat 1. The rubber strip 2 and the sealing ring 3 are divided into one or more areas 12, and the sealing ring 3 is arranged in the divided area 12 and is located At the hole 4 connecting and fixing the upright 6 and the sliding seat 1; each area 12 is provided with two or more glue inlet and / or glue outlet holes 5. (In the figure, the same label is used for the glue inlet and the glue outlet, that is, "the glue inlet and / or the glue outlet 5", because in practice, it does not matter which one is the glue inlet. Which are the glue outlet holes, they may be used as glue inlet holes or glue outlet holes), the glue inlet and / or glue outlet holes 5 can either be set on the column 6 ( image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com