Intelligent magnetic biasing detection and processing device for inversion welding power supply

A technology of inverter welding power supply and processing device, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of reducing the dynamic response performance of the system and difficult to meet the welding process, so as to achieve easy realization and industrial application and realization Automatic processing, improve the effect of anti-disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment example the utility model is described further.

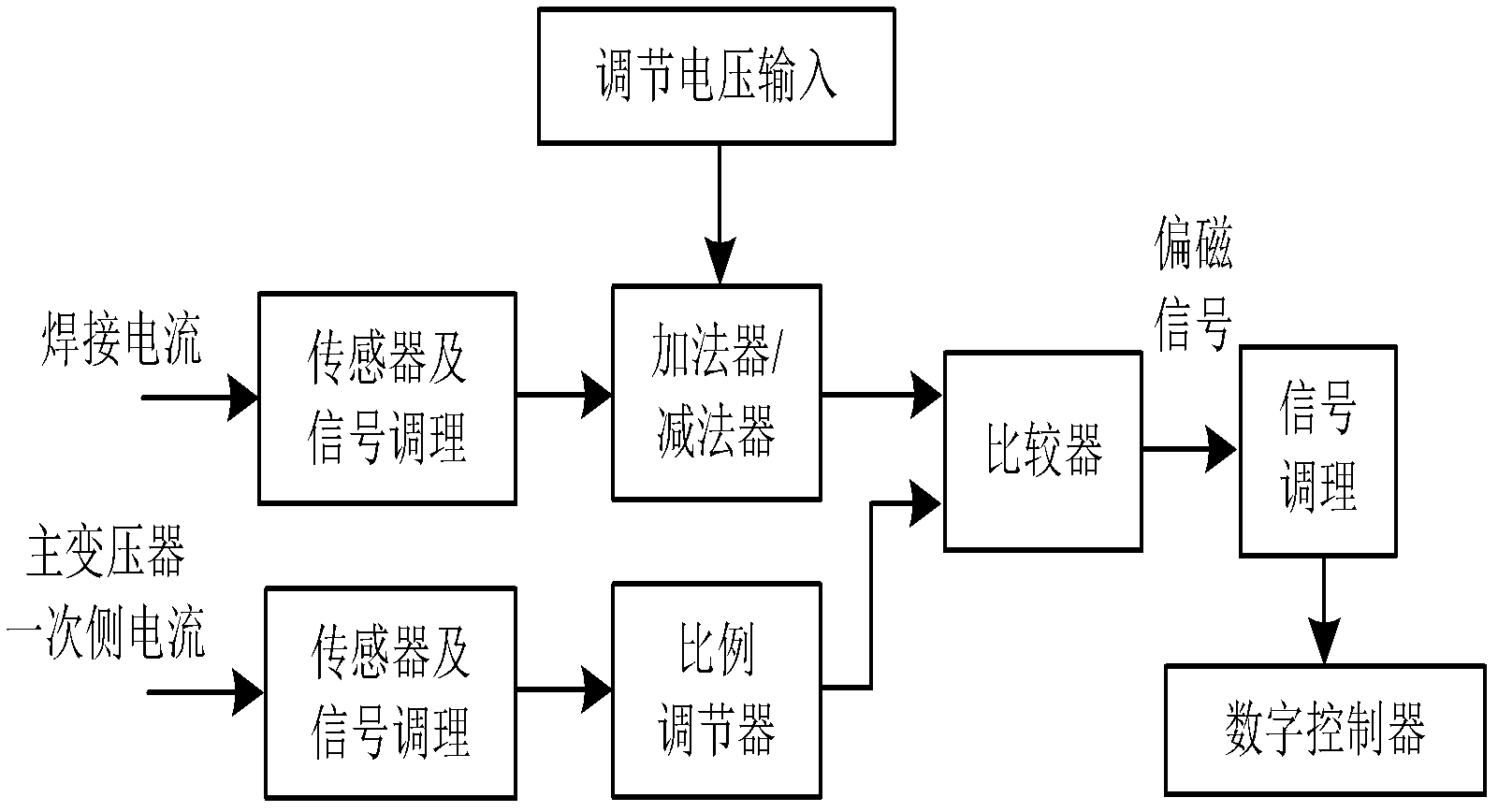

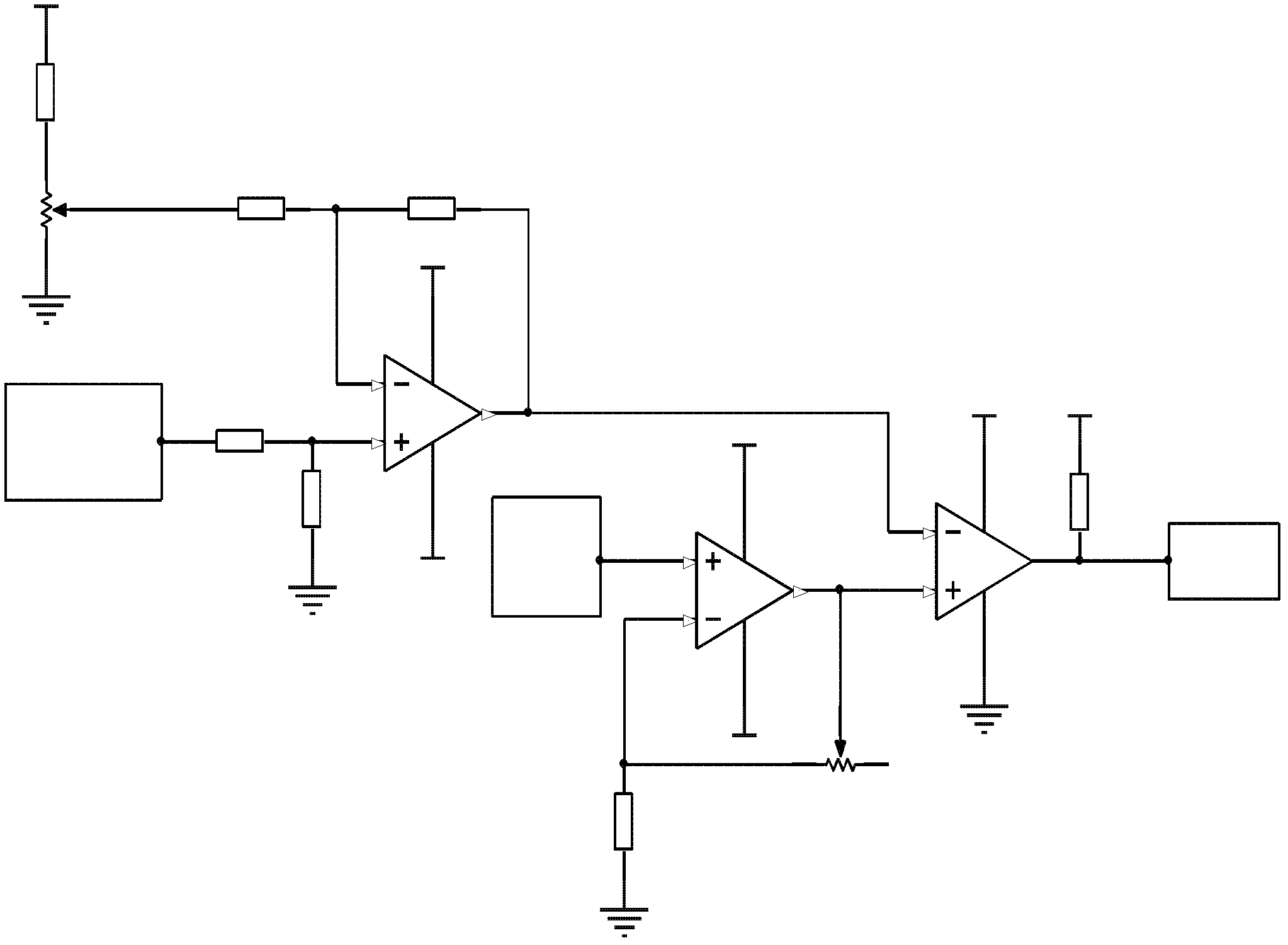

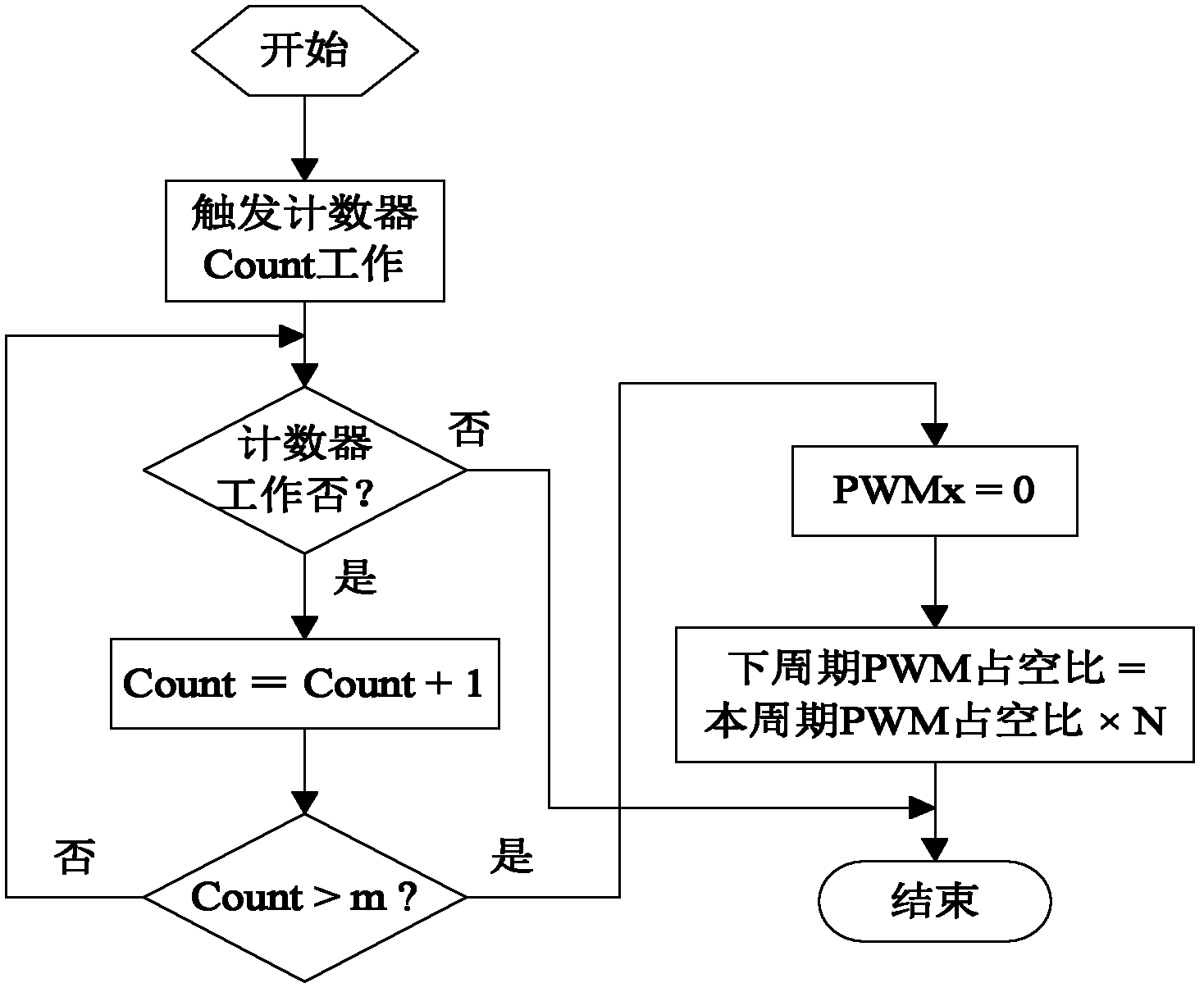

[0021] Inverter welding power supply intelligent magnetic bias detection and processing device, such as Figure 1~3 As shown, it includes a sensor and signal conditioning module, an adder / subtractor module, a proportional regulator, a comparator, a controller input signal conditioning module, a digital controller, and an adjustable voltage input module. Collect the welding current sensor and signal conditioning module, send the welding current signal processed by the sensor and signal conditioning module to the adder / subtractor module, adjust the voltage input module to send the signal to the adder / subtractor module, and the signal passes through the adder / subtractor module After being processed by the module, it is sent to the comparator; the primary side current of the main transformer is sent to the proportional regulator after being processed by the sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com