Needle valve and precise tiny electric spark processing method for conical surfaces of needle valve body

A precision machining and electric spark technology, which is applied in the field of micro EDM precision machining, can solve the problems of lowering the machining accuracy of the inner cone surface, shape error of the needle valve cone surface, and difficulty in machining, so as to achieve no mechanical cutting force and improve the shape error. , The effect of high processing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

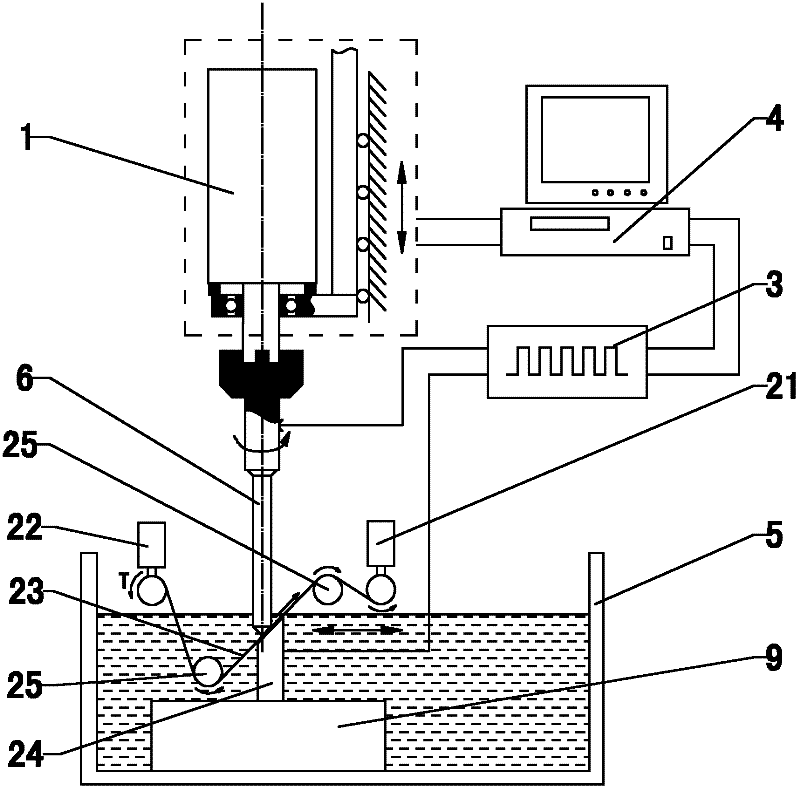

[0033] Such as figure 1 and image 3 As shown, the device of this embodiment includes a rotating spindle mechanism 1, a wire electrode wire mechanism, a pulse power supply 3, a numerical control system 4, a liquid tank 5, a needle valve 6, a needle valve body 7, a tool electrode 8 and a tooling 9; the rotating spindle mechanism 1. It can clamp the needle valve 6 or the tool electrode 8 to realize up-and-down movement and rotary movement. The whole movement process is controlled by the numerical control system 4; the wire-electrode wire-feeding mechanism includes a wire-feeding motor 21, a torque motor 22, an electrode wire 23, and a guide block 24 , guide wheel 25, wherein, wire-feeding motor 21 is active motor, drives electrode wire 23 to advance with lower speed (speed range: 0~25mm / min), and torque motor 22 outputs constant torque, keeps the tension force of electrode wire, The guide block 24 can control the cone angle of processing and transfer the electric energy of the ...

Embodiment 2

[0042] The processing device of this embodiment is different from Embodiment 1 in that: the shape, position and direction of the guide block 24 and the guide wheel 25, the electrode wire 23 is placed on the front end protruding part of the guide block 24 and vertically by the conversion of the guide wheel 25 on the axis of the needle valve.

[0043] Such as figure 2 As shown in b, the outer cone surface of the needle valve of the diesel engine fuel injector assembly in this embodiment includes the following steps:

[0044] (1) Roughly machine the outer cone surface at the top of the needle valve 6 in advance;

[0045] (2) Winding the electrode wire 23 on the EDM wire electrode wire running mechanism, connecting the pulse power supply 3 negative pole for EDM with the guide block 24;

[0046] (3) Install the needle valve 6 in the rotating spindle mechanism 1, and connect the positive pole of the pulse power supply 3 for EDM with the needle valve 6;

[0047] (4) Inject the wo...

Embodiment 3

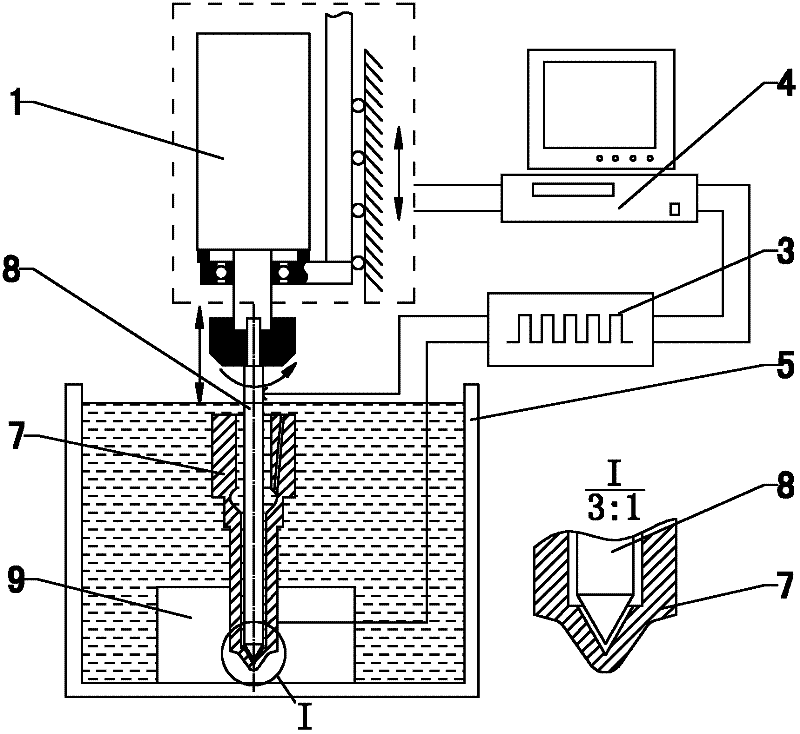

[0051] The processing device of this embodiment differs from that of Embodiment 1 in that: the wire-feeding mechanism is removed, and the tooling 9 is changed to a tooling for fixing the needle valve body.

[0052] Such as image 3 As shown, the taper surface inside the needle valve body of the diesel engine fuel injector pair in this embodiment includes the following steps:

[0053] (1) Roughly machine the inner cone surface in the needle valve body 7 in advance;

[0054] (1) Fix the needle valve body 7 on a specific tooling 9, and connect the positive pole of the pulse power supply 3 for electric sparks to the needle valve body 7;

[0055] (2) Install the pre-processed tool electrode 8 that is consistent with the shape of the outer cone of the needle valve 6 on the rotating spindle 1, and connect the negative pole of the pulse power supply 3 for electric discharge machining to the electrode;

[0056] (3) Inject the working fluid into the liquid tank 5 to ensure that the ED...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com