Dry method processing process and device for corn

一种干法加工、玉米的技术,应用在谷物处理、农业、应用等方向,能够解决成品率低、很难分离、脱皮率低等问题,达到含砂量降低、经济和社会效益巨大、洁净度和食用品质提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

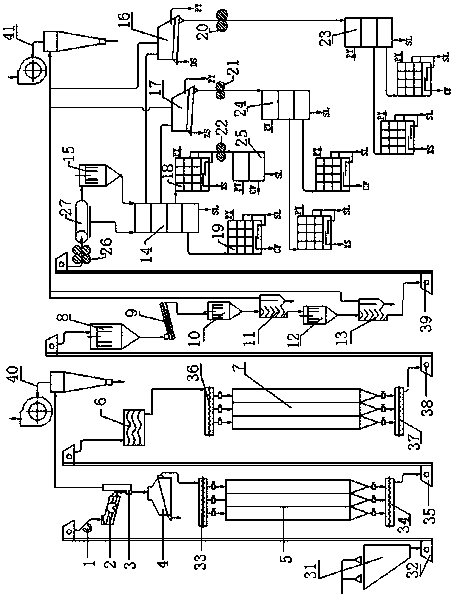

[0027] A kind of corn dry processing technology, the technological process is mainly: magnetic separation → screening → stone removal → raw corn storage → tempering → moistening corn → first stirring and peeling → watering → second stirring and peeling → first The first air selection → the third stirring and peeling → the second air selection → degerming and breaking of grits → embryo selection and grits extraction.

[0028] A device (such as figure 1 shown), the device includes a magnetic separator 1, a vibrating screen 2, a vertical suction duct 3, a destoner 4 (the destoner 4 is connected to the corn bin 5 through the first screw conveyor 33), the wool Corn bin 5 (the raw corn bin 5 is connected to the water vapor conditioner 6 via the second screw conveyor 34, the second hoist 35), the water vapor conditioner 6 (the water vapor conditioner 6 is connected to the wet corn bin 7 through the third screw conveyor 36 connection), moist corn bin 7 (moisten corn bin 7 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com