Preparation method of distiller's grain adsorbing material for heavy metal ion adsorption

A technology for heavy metal ions and adsorbent materials, which is applied in the field of preparation of adsorbent materials for discarded lees of liquor, and achieves the effects of realizing waste recycling, great practical value and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

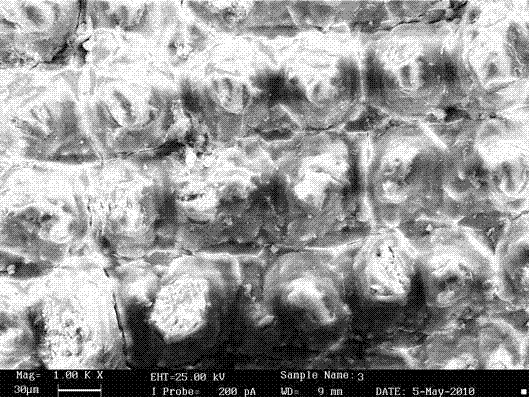

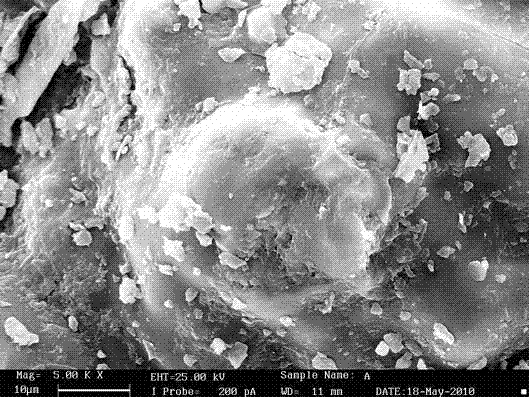

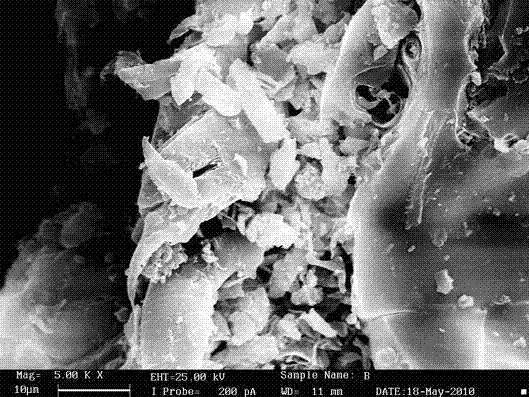

Image

Examples

Embodiment 1

[0033] Select the by-products produced by Luzhou-flavor liquor, and after natural drying, crush, pass through a 60-mesh sieve, and the under-sieve is the pre-treatment discarded grains; add 5 parts by weight (the unit can be kilograms, the same below) Add 50 parts by weight of a solution of hydrochloric acid, sodium hydroxide alkali and sodium carbonate with a concentration of 5% by mass, soak at a temperature of 60°C for 2 hours, filter, wash with 2 to 5 times the weight of water, and grind After that, the absorbent material for liquor discarded grains is obtained.

Embodiment 2

[0035] Select the by-product discarded grains produced by Luzhou-flavor liquor, after natural drying, pulverize, pass through an 80 mesh sieve, and the under-sieve is the pretreated discarded grains; 15 parts by weight of the pretreated discarded grains are added to 200 parts by weight In a solution of sulfuric acid, potassium hydroxide and sodium chloride with a concentration of 10%, soak at 100°C for 4 hours, filter, wash with 2 to 5 times the weight of water, dry at 40°C, and grind to obtain Absorbent material for liquor waste.

Embodiment 3

[0037] Choose the by-products produced by Luzhou-flavor liquor to lose grains, after natural drying, pulverize, pass through a 100-mesh sieve, and the under-sieve is the pre-treatment waste grains; add 30 parts by weight of dried distillers grains to a mass percentage concentration of 300 parts by weight It is a solution of 20% nitric acid, ammonia water and zinc chloride, soaked at 120°C for 5 hours, filtered, washed with 2 to 5 times the weight of water, dried at 50°C, and ground to obtain liquor distilled grains Adsorbent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com